A wireless power transfer resolver suitable for high temperature and high pressure environments

A wireless power transmission, resolver technology, applied in the direction of transformer, transformer/inductor shell, transformer/inductor magnetic core, etc., can solve the problems of sliding wear, inability to apply, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the drawings and embodiments.

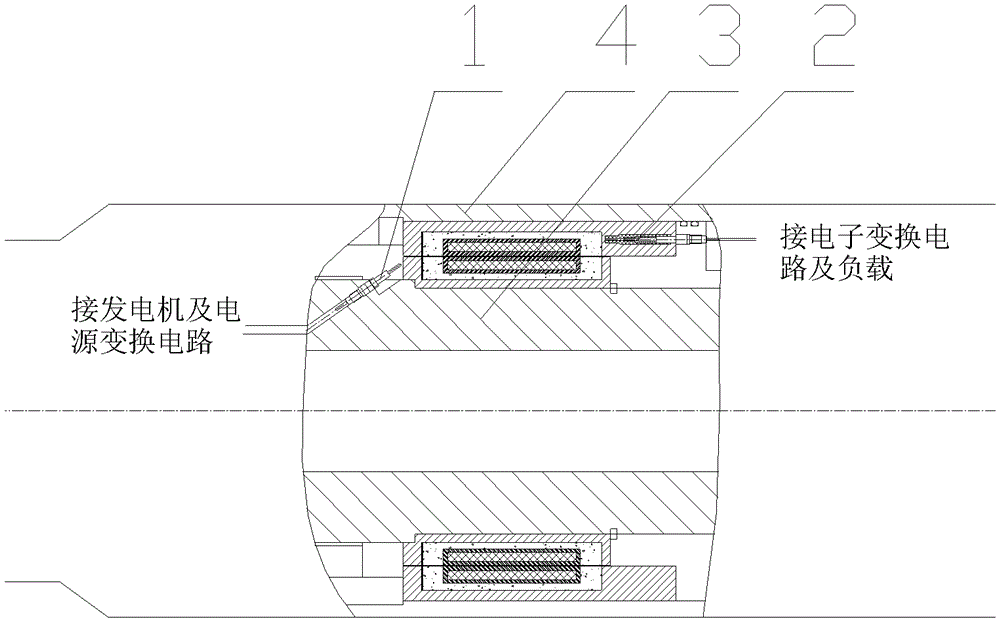

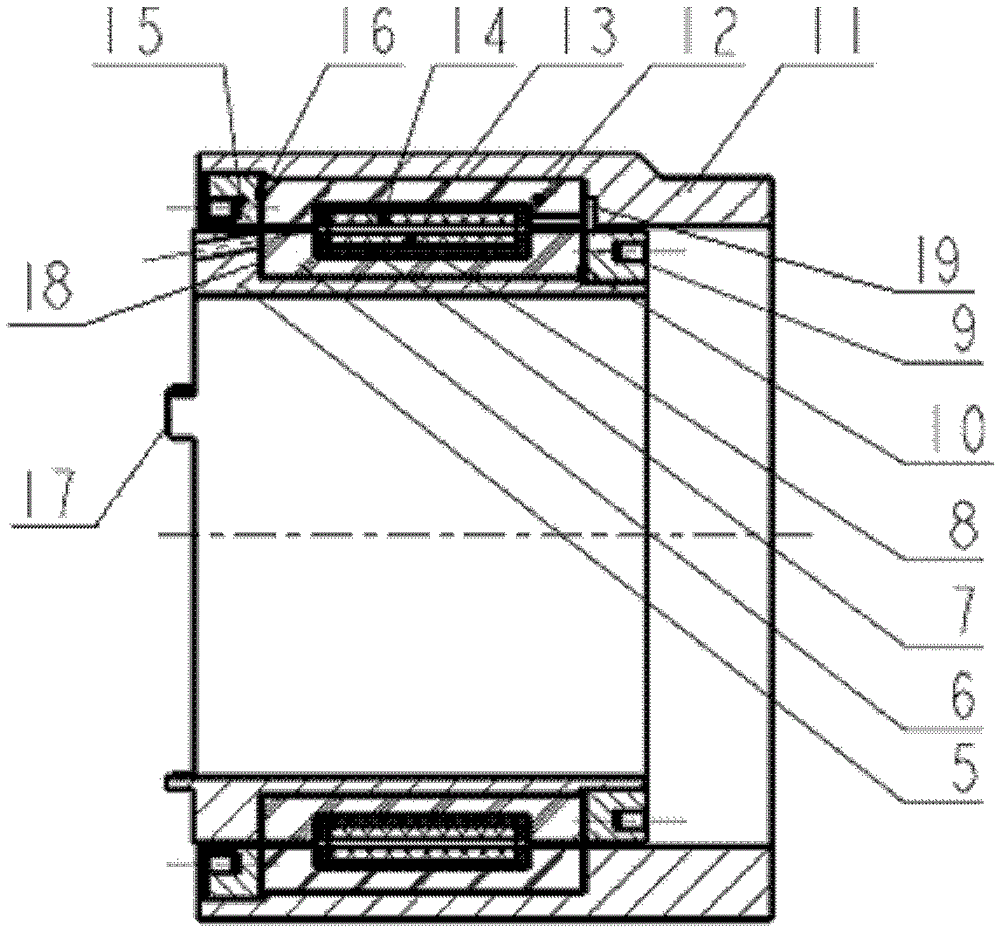

[0020] A wireless power transmission resolver suitable for high-temperature and high-pressure environments is arranged in the annular cavity between the outer tube 4 and the inner tube 3 of the automatic vertical drilling tool below the ground plane, including the passing limit card 17 and the inner tube 3 The slot on the outer wall of the outer wall is engaged with the fixed cylindrical primary side steel shell 5, which is fixed to the cylindrical secondary side steel shell 11 in the inner wall of the outer tube 4 by pins; the outer wall of the primary side steel shell 5 is provided with a first annular concave The groove adopts a "┗┛"-shaped structure with a circumferential flange at one end of the outer wall and the axial section is axisymmetric; the inner wall of the secondary side steel shell 11 is provided with a second annular groove, and one end of the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com