On-line pretreatment device of chromatographic gas sample and application method thereof

A pretreatment device and chromatographic technology, which is used in measurement devices, instruments, scientific instruments, etc., to ensure long-term effective operation, accurate analysis data, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

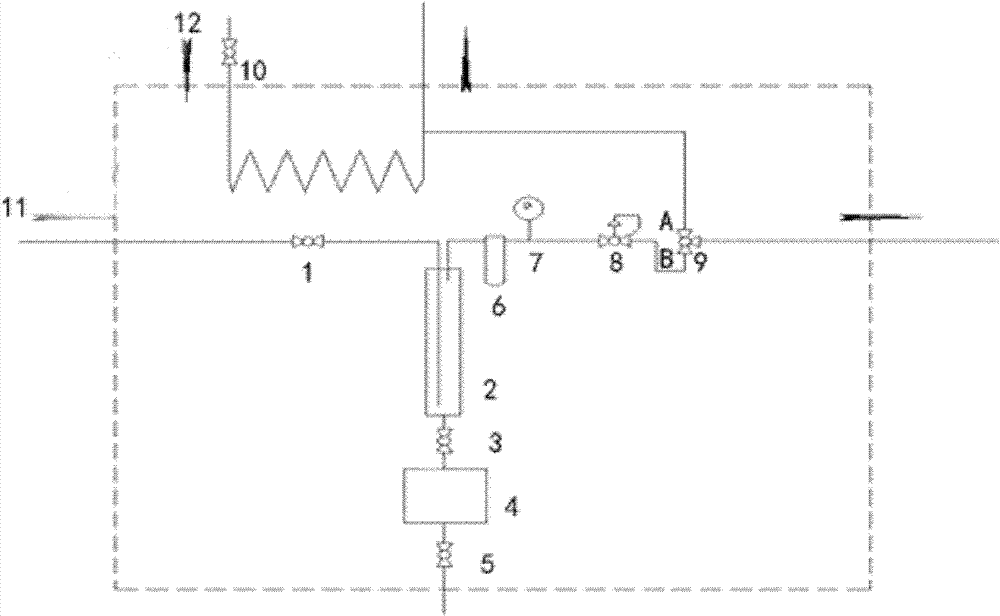

[0031] (1) Pretreatment device for online chromatographic analysis of ethylene cracking furnace sample gas:

[0032]Water and heavy hydrocarbons are entrained in the sample gas of the ethylene cracking furnace; the pretreatment device includes: a box body 11, a buffer settling tank 2, a visible drain tank 4 that can observe the liquid level, a drain valve 5, and a gas filter 6. The pressure regulating valve 8 is located behind the pressure regulating valve 8 and the cleaning switching valve 9 is used to heat the steam heating pipeline 10 of the box body 11, the box body insulation layer, and the connecting pipeline; the connecting pipeline of the pretreatment device is made of stainless steel, Its inner surface is treated with super-hydrophobic paint to form an ultra-micro-nano structure with low surface tension, and the wall surface is distributed with small protrusions of about 10 microns composed of an ultra-micro structure of about 100 nanometers; the cleaning switching val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com