Compact type full spectrum optical measuring head device used for reflection difference spectral measurement

A reflective differential spectroscopy, compact technology, which is applied in the field of precision testing technology and surface optical characterization, can solve the problems of inability to obtain small-sized light spots, weaken the mobile performance of equipment, and different refractive indices, so as to compress the peripheral space and promote The balance of spectral light intensity and the effect of enhancing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in combination with specific embodiments.

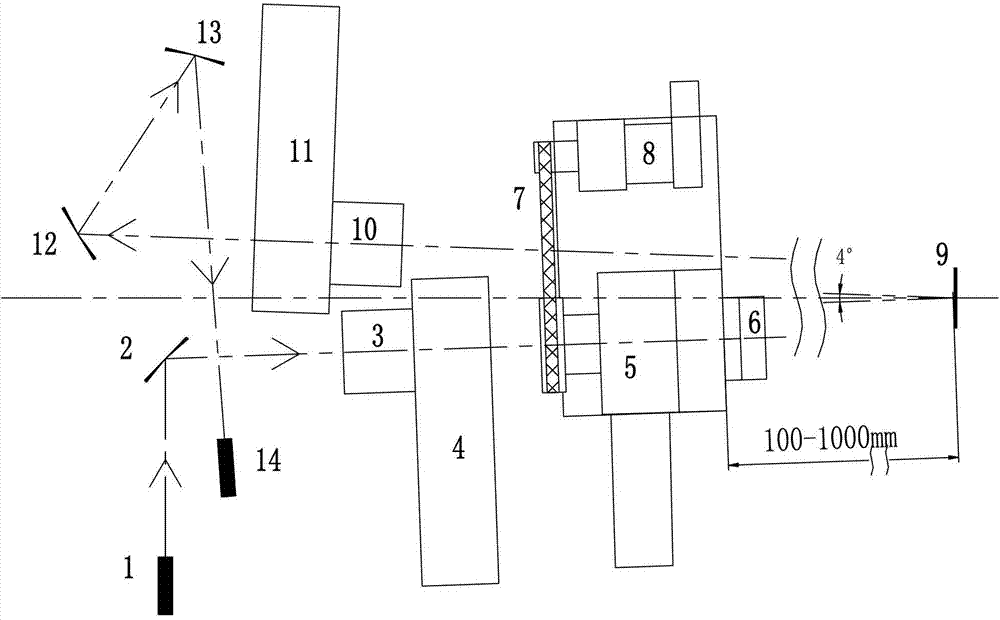

[0022] As shown in the accompanying drawings, the present invention is a compact full-spectrum optical measuring head device for reflective differential spectrum measurement, including an incident optical fiber 1, an off-axis parabolic mirror 2, a polarizer 3, a rotary compensator 6, and a polarizer device 10, a first concave mirror 12, a second concave mirror 13 and an outgoing optical fiber 14. The off-axis angle of the off-axis parabolic mirror 2 is one of 90 degrees, 60 degrees, 45 degrees and 30 degrees. The polarizer 3 and the polarizer 10 are respectively installed on a respective rotating platform, and each rotating platform is respectively connected with a stepping motor. The rotary compensator 6 includes an achromatic wave plate installed on a rotary table, and the rotary table consists of a DC continuous motor 8, a transmission belt 7, an angle sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com