Sealing structure for case-penetrating pipelines

A sealing structure and pipeline technology, applied in the direction of pipes, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of collision pipes, easy scratches, and increased difficulty in assembly work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

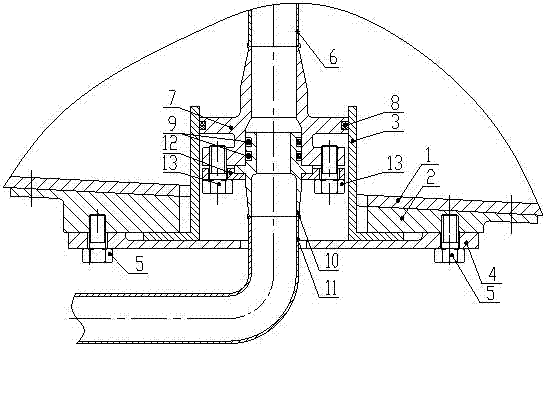

[0020] This embodiment provides a pipeline sealing structure passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a floating sleeve 3, a mounting seat pressure plate 4, bolts 5, conduits 6, and special-shaped joints 7. Expansion ring 8, sealing ring 9, movable joint 10, conduit 11, pressure plate 12, bolt 13;

[0021] Among them: the casing mounting seat 2 is welded or riveted on the casing 1, the mounting seat pressure plate 4 is fixed on the casing mounting seat 2 by 4 or 6 bolts 5, and the floating sleeve 3 is connected with the casing mounting seat 2 and the mounting seat. The pressure plate 4 has a gap fit, and can freely move 1~3mm in the circumferential direction. The expansion ring 8 is installed on the special-shaped joint 7, and cooperates with the floating sleeve 3 with a small gap. The conduit 6 and the special-shaped joint 7 are welded together, and the special-shaped joint 7 is lower than the casing. Contain...

Embodiment 2

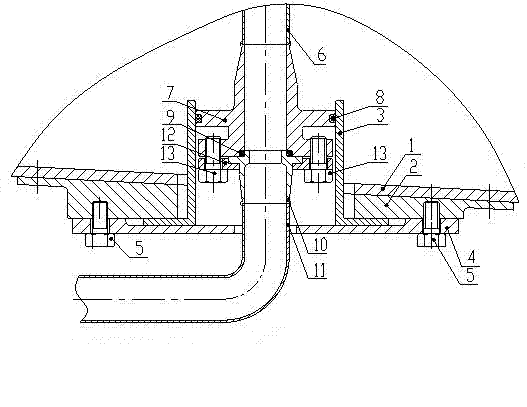

[0031] This embodiment provides a pipeline sealing structure passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a floating sleeve 3, a mounting seat pressure plate 4, bolts 5, conduits 6, and special-shaped joints 7. Expansion ring 8, sealing ring 9, movable joint 10, conduit 11, pressure plate 12, bolt 13;

[0032] Among them: the casing mounting seat 2 is welded or riveted on the casing 1, the mounting seat pressure plate 4 is fixed on the casing mounting seat 2 by 4 or 6 bolts 5, and the floating sleeve 3 is connected with the casing mounting seat 2 and the mounting seat. The pressure plate 4 has a gap fit and can freely move 1~3mm in the circumferential direction. The expansion ring 8 is installed on the special-shaped joint 7 and cooperates with the floating sleeve 3 with a small gap. The conduit 6 and the special-shaped joint 7 are welded into one body, and the special-shaped joint 7 is lower than the casing Conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com