Multistage dry vacuum pump

A dry vacuum pump, multi-stage cylinder technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve problems such as high cost, achieve the effects of overcoming leakage, enhancing cooling performance, and enhancing cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Some preferred embodiments of the invention will be described with reference to the accompanying drawings.

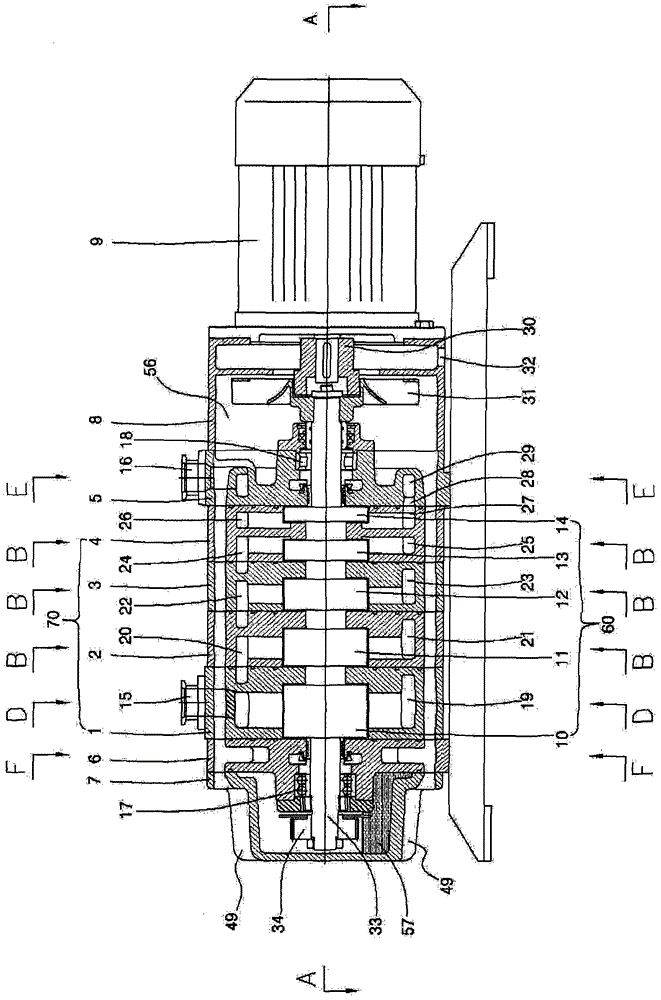

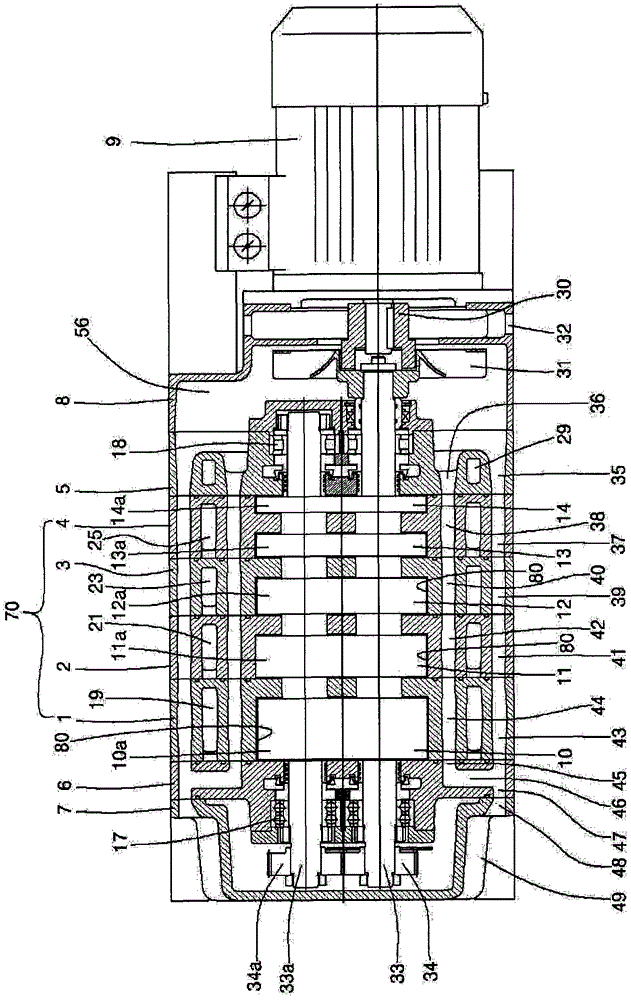

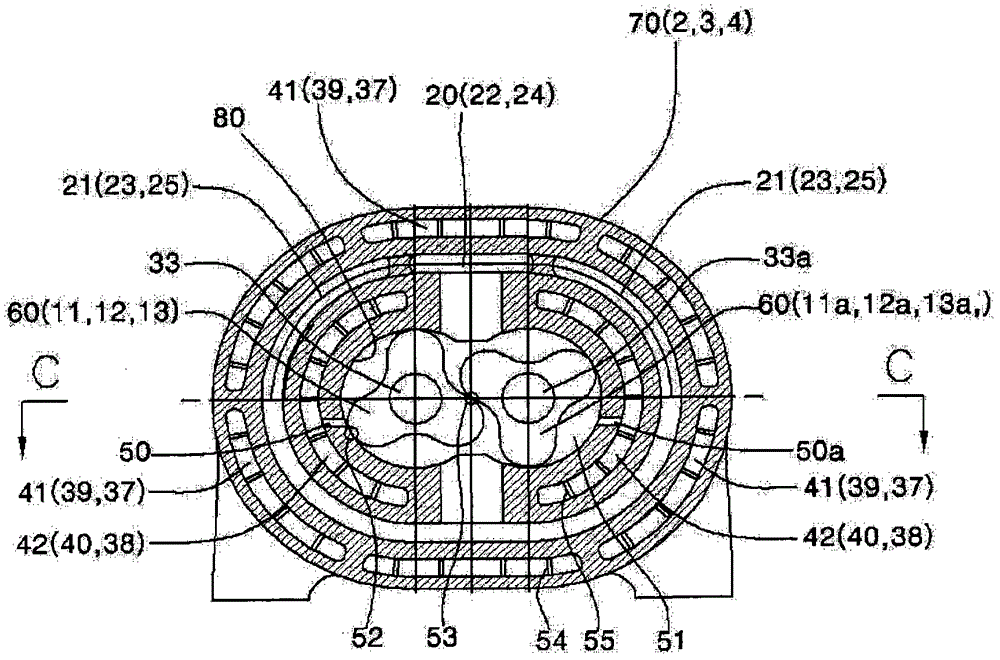

[0035] Figures 1 to 8 is a view showing a multi-stage dry vacuum pump according to the present invention, and the dry vacuum pump is a multi-stage Roots type in which a pair of pump rotors is accommodated in an inner accommodation space of each cylinder (casing).

[0036] Such as figure 2As shown, the vacuum pump apparatus includes a pair of rotors 10, 11, 12, 13, 14 and 10a, 11a, 12a, 13a, 14a, 15a (hereinafter referred to by reference numeral 60) and is rotatably supported by bearings 17 and 18 The shafts 33 and 33a, and the pair of rotors are arranged in the peanut-shaped inner housing space 80 formed in the cylinders 1, 2, 3, 4. The rotors in each cylinder 1, 2, 3, 4 (indicated by reference numeral 70) are arranged at regular intervals and mounted on shafts 33 and 33a.

[0037] The vacuum pump includes a suction port 15 arranged on the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com