Energy-saving waterproof fireproof opening cover for decorative door or window opening

A technology for door and window openings and muzzles, which is applied to fire doors, war damage prevention, window/door frames, etc., and can solve problems such as secondary heat preservation, hidden dangers of waterproof quality, unreasonable misalignment of window frames, and unstable installation of window frames, etc. , to achieve the effect of improving the quality of appearance engineering, simplifying the construction process, improving the effect and building quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

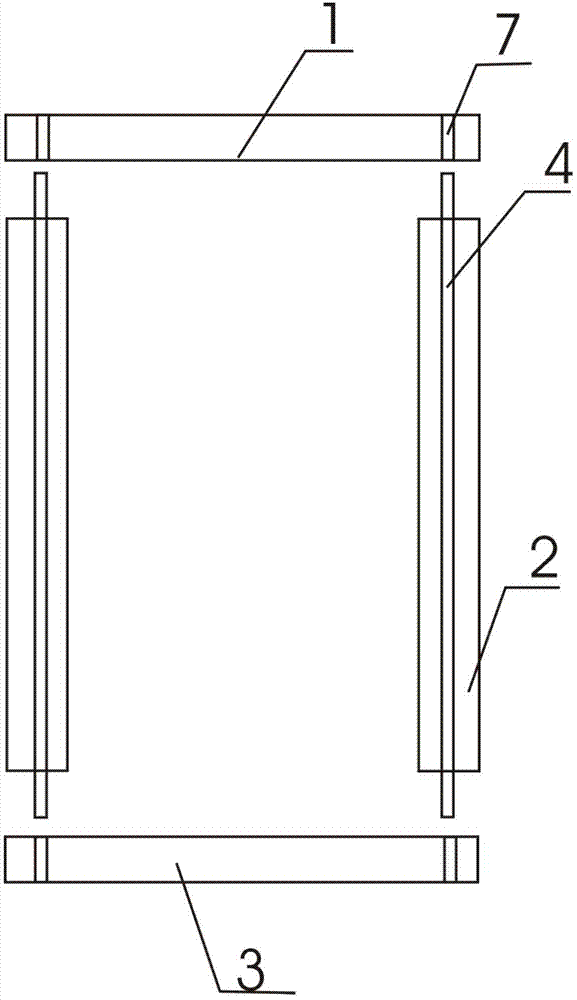

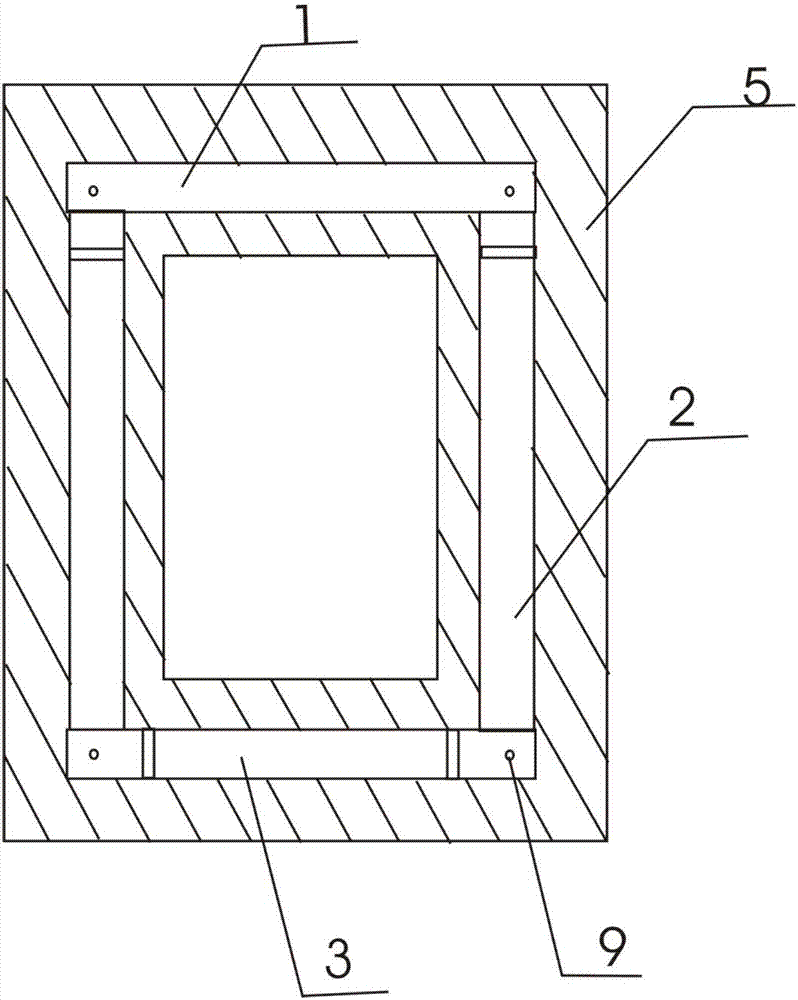

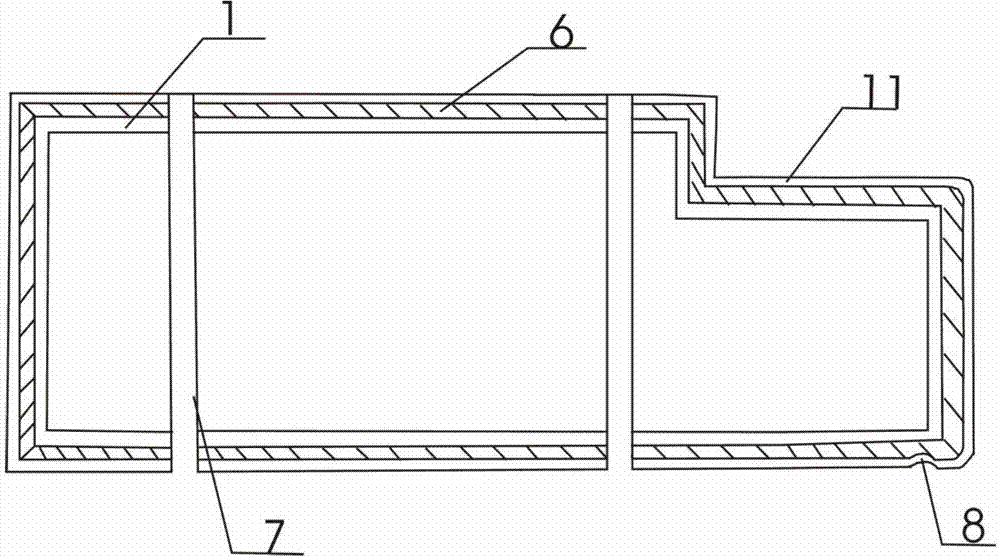

[0016] First, according to the design of the outer eaves door window of the building, the molds of the upper frame 1, the side frame 2 and the lower frame 3 are made with the thermal insulation frame; then the connection jacks are respectively set on the upper frame and the lower frame 7. Then fix the connecting member 4 in the side frame 2, set up a drip tank 8 outside the upper frame 1 and the lower frame 3, and then fix the lower frame 3 and the metal connecting seat 10 together by fixing bolts 9 , respectively manufacture the prototypes of the upper frame 1, side frame 2, and lower frame 3; spray cement-based reinforced waterproof layer 6 on the surface of the prototype; then decorate the exterior according to customer needs, or decorate the The decorative surface layer 11 is fixed on the present invention; finally, the installed and decorated assembling muzzle is temporarily fixed on the reinforcing pallet 5 which plays the roles of reinforcement, transportation, hoisting ...

Embodiment 2

[0018] when using it:

[0019] The first step is to mark the installation position of the "hole sleeve" and the position of the temporary fixing bolt hole;

[0020] The second step is to install the fixing bolts 9 on the upper frame 1 and the lower frame 3;

[0021] The third step is to clean the surface of the reserved door and window openings;

[0022] The fourth step is to push the "opening cover" fixed on the reinforcement pallet 5 together with the reinforcement pallet 5 from the inside of the building to the opening of the door and window, and then remove the reinforcement pallet 5;

[0023] The fifth step is to adjust the "hole mouth cover" and align the connecting jack 7 with the position of the metal connecting seat 10, and then temporarily fix it with the fixing bolt 9, and then insert the fixing bolt 9 into the connecting jack of the lower mouth frame 3, and then put the The fixing bolt 9 is inserted into the connection socket 7 of the side opening frame 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com