sprinkler connection box

A technology of sprinkler and connection box, which is applied to building components, on-site preparation of building components, ceramic molding machines, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

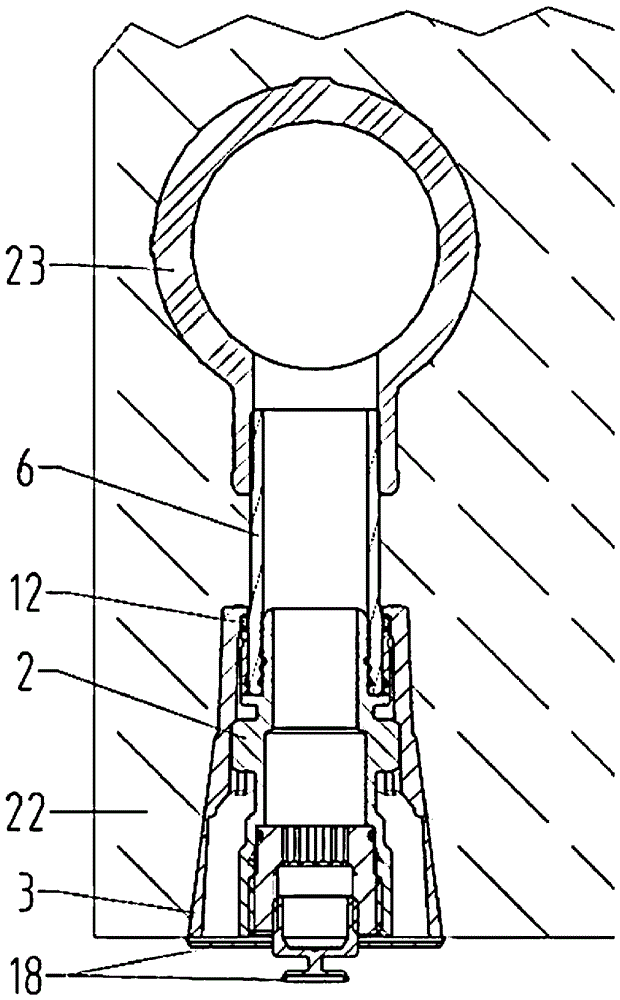

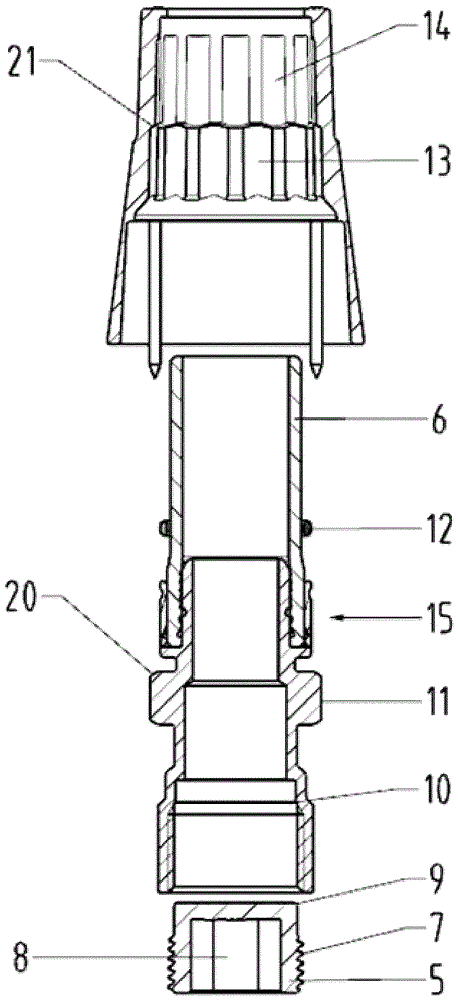

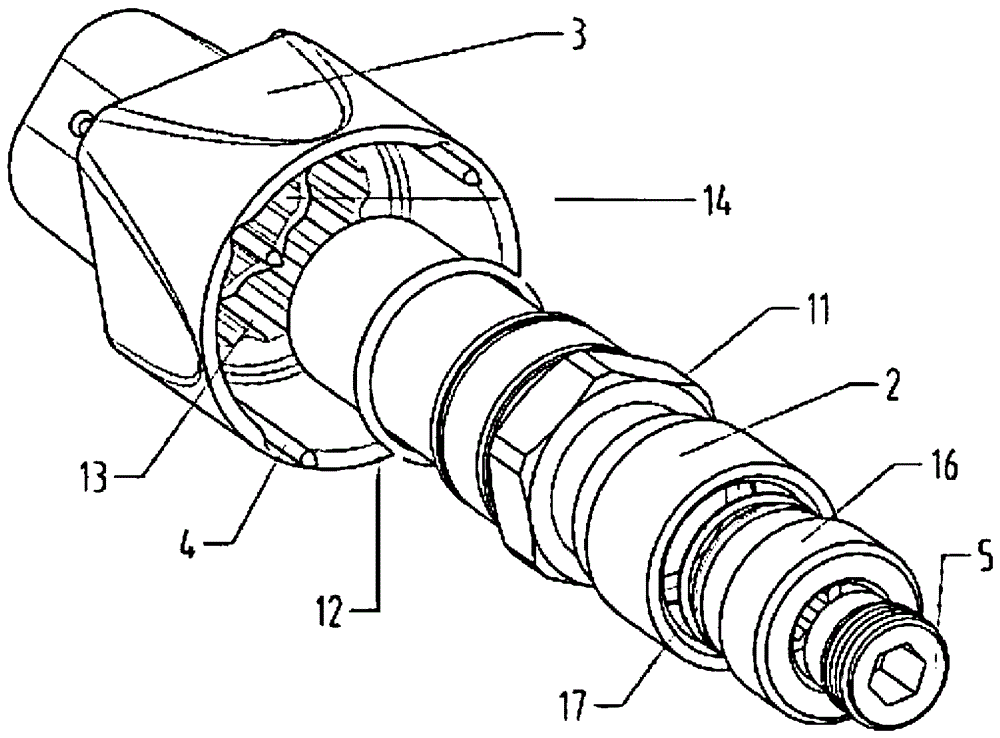

[0049] figure 1 Shown is the sprinkler connection box 1 as received when delivered pre-assembled to the installation engineer, already assembled ready to be installed in a suspended ceiling. All the installation engineer needs to do is to hammer the sprinkler connection box 1 to the cladding panel using fastening means 4, preferably nails, so that the sprinkler connection box 1 is positioned such that it is fixed in all directions. The engineer must then connect the transition piece 6 to the sprinkler pipe 23, possibly by means of a welded joint. Usually, multiple sprinkler connection boxes 1 are connected to the sprinkler pipes, so the simple installation saves a lot of assembly time. Once the sprinkler connection box 1 has been connected, a seal test can be performed directly to test the tightness of the system's seal. Since the plug 5 ensuring the tightness of the seal is already pre-assembled in the sprinkler connection box 1, the installation engineer does not need (as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com