Automatic control system for quartering hammers of crawler type hydraulic excavator

An automatic control system, hydraulic excavator technology, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problem of high failure rate of hydraulic system and structural parts, exceeding the use range of the breaker, working conditions meeting the parameters of working flow, Problems such as working pressure and impact frequency are difficult to range, so as to achieve the effect of improving service life, high working efficiency and low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

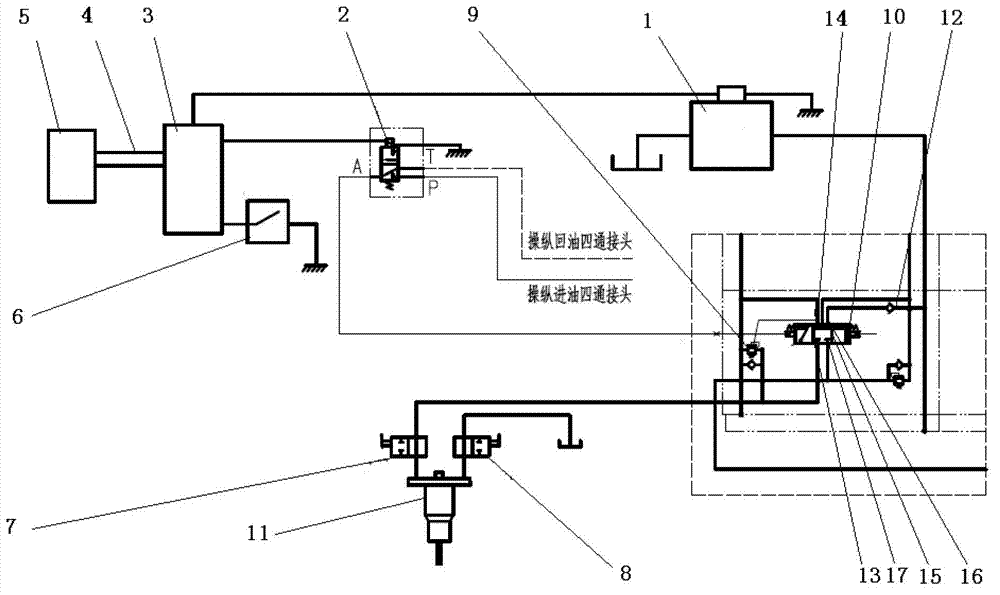

[0030] The present invention provides an automatic control system for a breaker hammer of a crawler hydraulic excavator. The system includes an electrical system, a hydraulic system, and an actuator; the electrical system mainly includes a central controller 3, a CAN bus 4, a monitor 5, a pedal Switch 6; the hydraulic system mainly includes a main pump 1, a breaker solenoid valve 2, a first ball valve 7, a second ball valve 8, an overflow valve 9, and a main valve 10; the actuator mainly includes a breaker 11; its characteristics In that: the control end of the main pump 1 is connected to the central controller 3, the oil inlet of the main pump 1 is connected to the fuel tank, and the oil outlet is connected to the first oil port 16 of the main valve through the first one-way valve 12; The breaker solenoid valve 2 is connected with the central controller 3, the T oil port of the breaker is in fluid communication with the steering oil return four-way joint, the P oil port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com