Reinforced concrete inspection well whole prefabricated hoisting construction method

A reinforced concrete and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of failure to install concrete inspection wells, affect the next process, and fail to guarantee quality, etc., and achieve economic and social benefits Significantly, the effect of improving construction efficiency and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

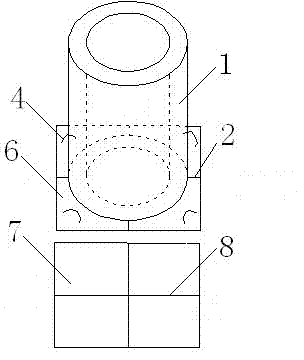

[0023] Accompanying drawing is a kind of specific embodiment of the present invention. The realization process of this invention is:

[0024] 1. Construction preparation

[0025] 1) Check the operation of vibration rods, electric welding machines, cranes, loaders, electric rust removal brushes and other equipment;

[0026] 2) Conduct construction technology disclosure and safety disclosure to the construction team, and provide relevant training;

[0027] 3) Check whether the quality of the release agent and steel bars can meet the quality requirements, and inspect the incoming goods such as the degree of agreement between the inner and outer steel formwork;

[0028] 4) Determine the control points for steel bar binding and concrete pouring and the basis for inspection and acceptance.

[0029] 2. Base plate formwork installation and reinforcement

[0030] After the base plate template is processed, apply the release agent and place it on the hardened ground with plastic fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com