Silicone resin containing alkenyl and preparation method thereof

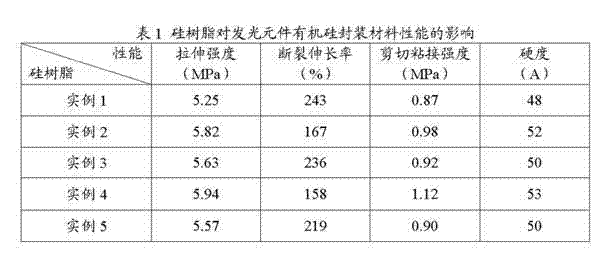

An alkenyl silicone resin, silicone resin technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of decreased luminous flux, poor heat resistance, molecular structure deformation, etc. Control, improve the mechanical strength, the effect of narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

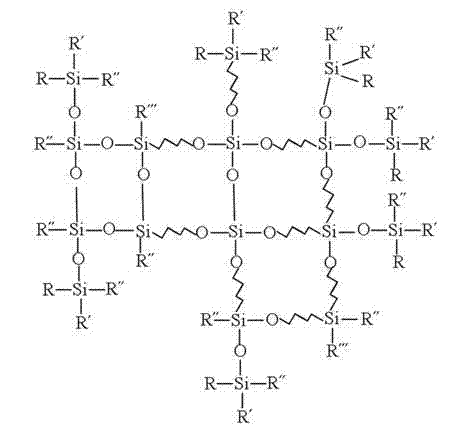

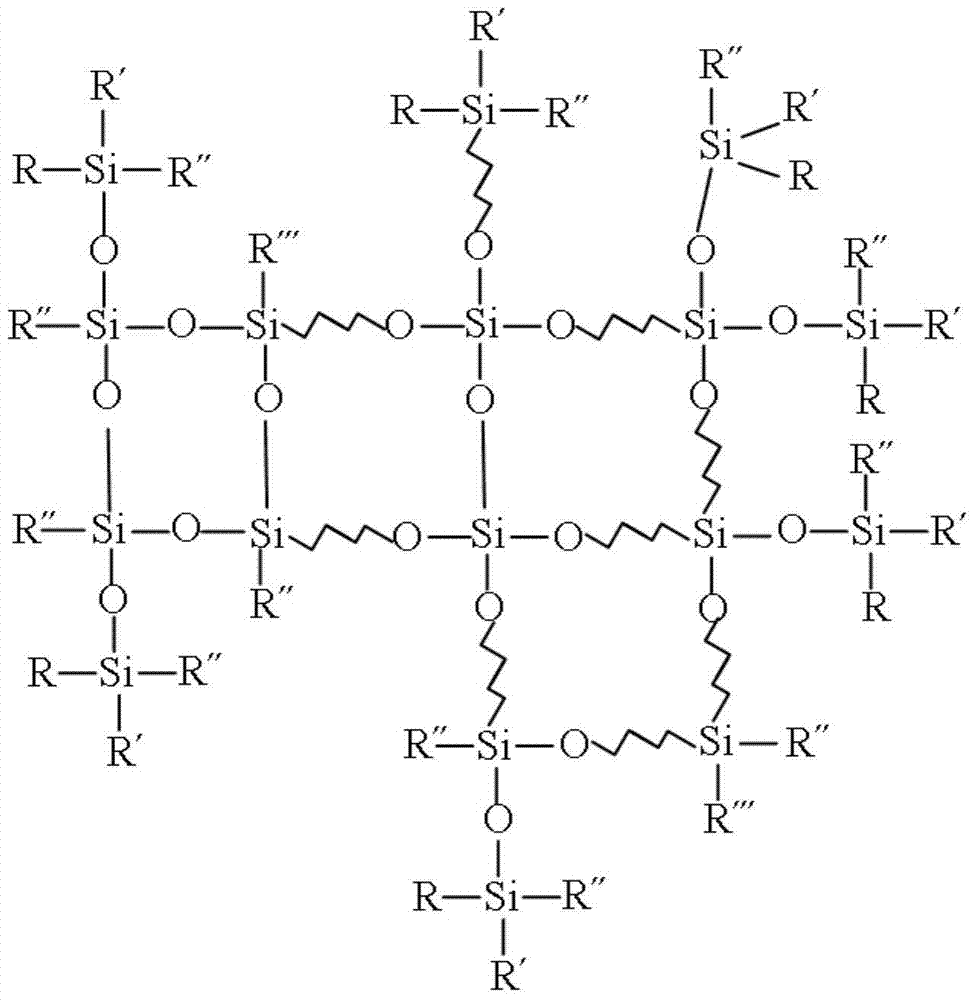

Method used

Image

Examples

Embodiment 1

[0034] Add 40 grams of distilled water, 120 grams of absolute ethanol, and 25 grams of 37% concentrated hydrochloric acid into a four-neck flask with stirring, reflux condenser, thermometer and dropping funnel, and stir to mix. Then add 130 grams of hexamethyldisiloxane (capping agent) and 39.6 grams of methylvinyldimethoxysilane, raise the temperature to 60 ° C, hydrolyze for 1 hour, and add 208.33 grams of ethyl orthosilicate dropwise under reflux (tetrafunctional organosilicon monomer), continue to stir for 1 hour of hydrolysis reaction. After the hydrolysis reaction was completed, 400 g of isododecane was added as an extractant. After the extraction reaction was performed for 3 hours, the mixture was allowed to stand for stratification, the water phase was removed, and the organic phase was washed with distilled water until neutral. The neutral organic phase was distilled under reduced pressure to remove the low boilers to obtain a colorless and transparent vinyl-containin...

Embodiment 2

[0036] Add 50 grams of distilled water, 120 grams of absolute ethanol, and 20 grams of 37% concentrated hydrochloric acid into a four-neck flask with stirring, reflux condenser, thermometer and dropping funnel, and stir to mix. Then add 150 grams of dodecamethylpentasiloxane and 12.1 grams of methylvinyldimethoxysilane, raise the temperature to 70 ° C, hydrolyze for 1.5 hours, add 208.33 grams of methyl orthosilicate dropwise under reflux, and continue stirring Hydrolysis reaction 2.5h. After the hydrolysis reaction was completed, 100 g of isohexadecane was added as an extraction agent. After the extraction reaction was completed for 0.5 h, the mixture was allowed to stand for stratification, the water layer was removed, and the organic phase was washed with distilled water until neutral. The neutral organic phase was distilled off under reduced pressure to remove low boilers to obtain vinyl-containing solid silicone resin.

Embodiment 3

[0038] Add 50 grams of distilled water, 120 grams of absolute ethanol, and 20 grams of 37% concentrated hydrochloric acid into a four-neck flask with stirring, reflux condenser, thermometer and dropping funnel, and stir to mix. Then add 55 grams of tetramethyldivinyldisiloxane and 12.1 grams of octenyl trimethoxysilane, raise the temperature to 60 ° C, and hydrolyze for 2.5 hours, add 208.33 grams of ethyl orthosilicate dropwise under reflux, and continue stirring Hydrolysis reaction 1.5h. After the hydrolysis reaction was completed, 300 g of hexamethyldisiloxane was added as an extraction agent. After the extraction reaction was completed for 0.5 h, the mixture was allowed to stand for stratification, the water layer was removed, and the organic phase was washed with distilled water until neutral. The neutral organic phase was distilled off under reduced pressure to remove low boilers to obtain octenyl-containing silicone resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com