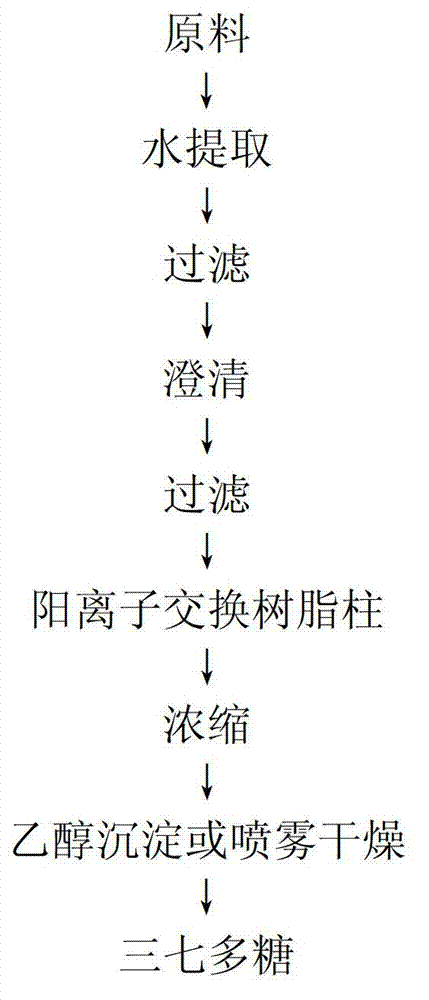

Method for reducing ash content of notoginseng polysaccharide

A technology of ash content and Panax notoginseng polysaccharide, which is applied in the field of extraction and removal of impurities of biological products, can solve the problem of not considering the influence of heavy metals and ash in Panax notoginseng extract, not considering the content of Panax notoginseng polysaccharide and ash, resin column regeneration and activation Difficulties and other problems, to achieve the effect of reducing the content of ash such as heavy metals, reducing the content of ash, and reducing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 100g of notoginseng residue dried after extracting notoginseng saponins, add 1000mL distilled water to soak for 6 hours, heat to 100°C to extract for 2 hours, filter, collect the filtrate, add 700mL distilled water to the filter residue, heat to 100°C to extract for 2 hours, filter , collect the filtrate and merge with the first extraction filtrate, add 600mL distilled water to the filter residue and heat to 100°C for extraction for 2 hours, filter, collect the filtrate and merge the previous second extraction filtrate, cool the filtrate and centrifuge to obtain the extract, heat the extract to 50 °C decompression and vacuum concentration to 600mL, heated to 60°C, stirred and added ZTC clarifier prepared with a volume of 2% volume, left to clarify for 12 hours, and then centrifugally filtered to obtain a centrifugal clarified liquid, which was added to a 732-type cation exchange resin on the column, and washed with water until there is no sugar reaction, collect th...

Embodiment 2

[0020] Weigh 100g of notoginseng residue raw material after extraction of notoginseng saponins, soak in 1000mL distilled aqueous solution for 12 hours, heat to 92°C for extraction for 2 hours, filter through 2 layers of gauze, collect the filtrate, add 1000mL to the filter residue and heat to 92°C for extraction After 1.5 hours, filter through gauze, add the filtrate to the first extract, add 800 mL of distilled water to the filter residue and heat to 92°C for extraction for 1 hour, filter through gauze, incorporate the filtrate into the previous extract, and discard the filter residue. Leave the extract to cool, and centrifugally filter to get 3000mL of filtered extract, heat to 70°C, stir and add 101 fruit juice clarifier solution with 8% volume, keep warm and stir for 30min, cool naturally, place for clarification for 12 hours, centrifugally filter, collect centrifugal clarifier liquid, added to the 734-type cation exchange resin column, and washed with water until the sugar...

Embodiment 3

[0022]Weigh 100 g of the raw material after extraction of notoginseng saponins, add 2000 mL of distilled water and soak for 24 hours, heat to 92°C for extraction for 3 hours, filter through heated 2 layers of gauze, collect the filtrate, add 1500 mL of distilled water to the filter residue, heat to 92°C for 2 hours, multiply Heat 2 layers of gauze for filtration, combine the filtrate with the first extract, add 1000 mL of distilled water to the filter residue and heat to 92°C for extraction for 1 hour, filter with 2 layers of gauze, combine the filtrate with the previous two extracts, and discard the filter residue. Heat the extract to 60°C, depressurize to -0.08MPa, collect to 500mL, heat to 60°C, stir and add 5g chitosan powder, heat and stir for 30 minutes, leave to cool for 10 hours, centrifugal filter, centrifugal filter clarified liquid is added On the D001 cationic resin column, elute with distilled water, collect the eluting solution, recover the water under reduced pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com