Method for preparing aromatic amine from mixed nitrochlorobenzene

A technology of nitrochlorobenzene and nitroaniline, which is applied in the field of preparing aromatic amines, can solve the problems of short process flow, high separation cost, and large amount of three wastes, and achieve low energy consumption, lower production costs, and less generation of three wastes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

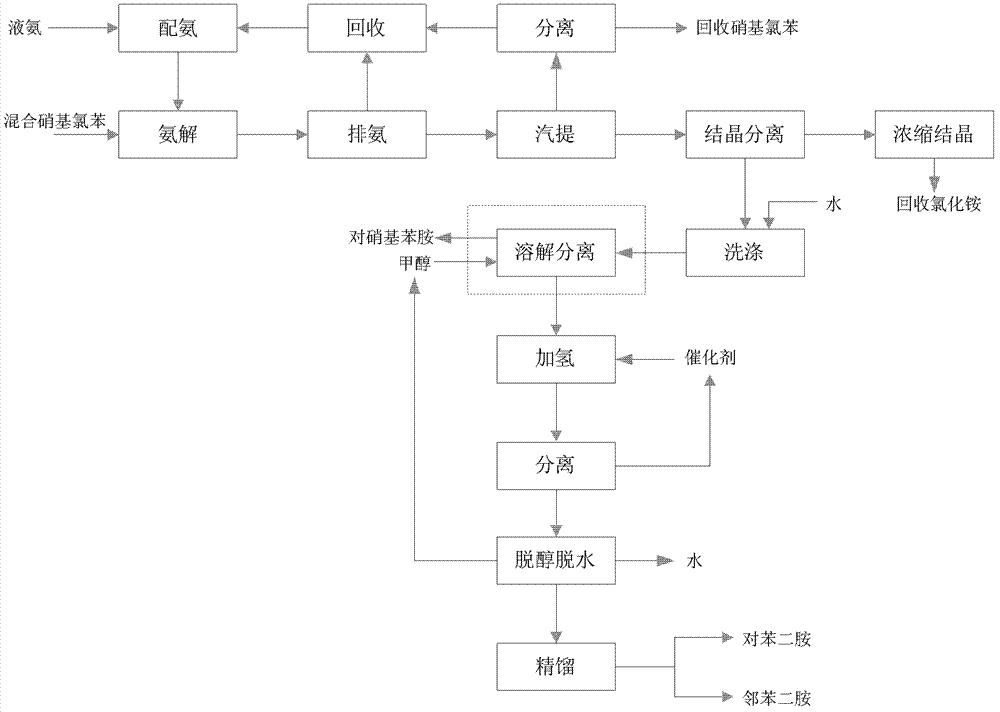

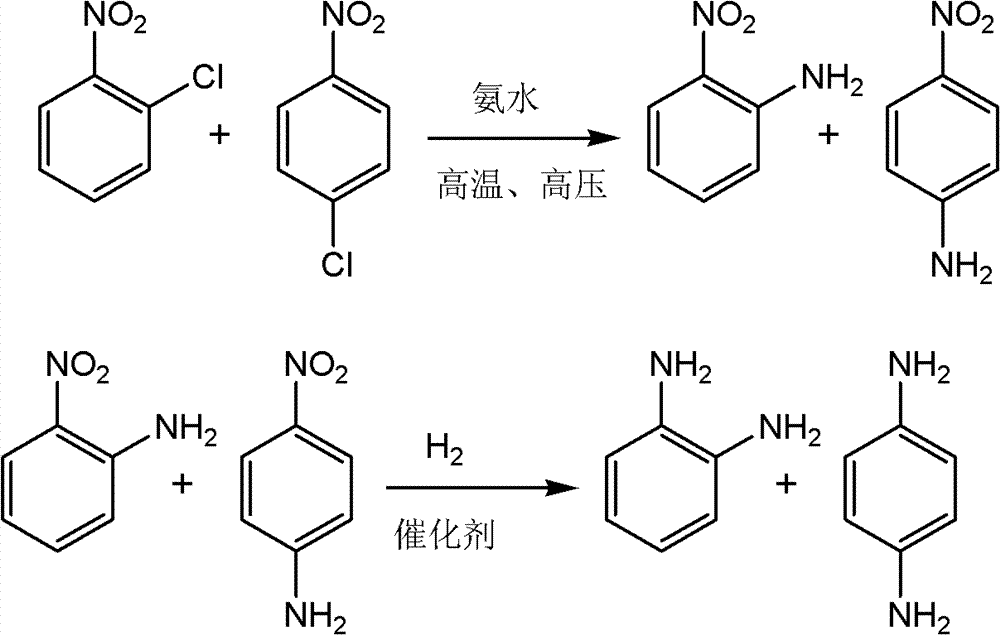

Method used

Image

Examples

Embodiment 1

[0023] 615kg of molten mixed nitrochlorobenzene (made by chlorobenzene through mixed acid adiabatic nitration, contains trace impurities, wherein the mass content of p-nitrochlorobenzene is 65.3%, the mass content of o-nitrochlorobenzene is 33.2%, and the mass content of m-nitrochlorobenzene chlorobenzene mass content is 0.8%) pumped into 3M 3 In a stirred reactor, mix it with 2220kg of 30% (w / w) ammonia water from the ammonia distribution tank under stirring, raise the temperature and control the temperature at 170-185°C and the pressure at 3.5-4.9MPa. Decomposition reaction for 10 hours, then lowered to about 145°C and began to discharge ammonia, the discharged gas was absorbed by water, used to prepare raw ammonia water for ammonolysis, the reactor material after ammonia discharge was pumped into the stripping tower, and stripped with 0.5MPa steam, Ammonia and nitrochlorobenzene are recovered by condensation at the top of the tower. The material after stripping was cooled,...

Embodiment 2

[0026] 650kg of molten mixed nitrochlorobenzene (made by chlorobenzene through mixed acid adiabatic nitration, contains trace impurities, wherein the mass content of p-nitrochlorobenzene is 64%, the mass content of o-nitrochlorobenzene is 34.5%, and the mass content of m-nitrochlorobenzene chlorobenzene mass content is 0.7%) pumped into 3M 3 In a stirred reactor, mix it with 2350kg of 33% (w / w) ammonia water from the ammonia distribution tank under stirring, raise the temperature and control the temperature at 160-182°C and the pressure at 4.0-4.9MPa. Decompose reaction for 10 hours, then cool down to about 145°C and start to discharge ammonia. The reactor material after ammonia discharge is pumped into the stripping tower, stripped with 0.5MPa steam, and the ammonia and nitrochlorobenzene are recovered by condensation at the top of the tower. After cooling, the material was cooled down to 35°C to crystallize, settled, and centrifuged to obtain 552 kg of mixed nitroaniline.

...

Embodiment 3

[0029] Pump 615kg of molten mixed nitrochlorobenzene (65.3% for p-nitrochlorobenzene, 33.2% for o-nitrochlorobenzene, 0.8% for m-nitrochlorobenzene) into 3M 3 In a stirred reactor, mix it with 2220kg of 30% ammonia water from the ammonia distribution tank under stirring, raise the temperature and control the temperature at 170-185°C and the pressure at 3.5-4.9MPa for 10 hours of ammonolysis reaction, Then it drops to about 145°C and starts to discharge ammonia. The discharged gas is absorbed by water, and is used to prepare raw ammonia water for ammonolysis. The reactor material after ammonia discharge is pumped into the stripping tower, stripped with 0.5MPa steam, and the ammonia is recovered by condensation at the top of the tower. and nitrochlorobenzene. The material after stripping was cooled, cooled to 30°C to crystallize, left to settle, and centrifuged to obtain 527 kg of mixed nitroaniline. The centrifuged mother liquor could be further processed to concentrate and cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com