Method for treating oily wastewater through ozone and electrochemical synergistic oxidization

An ozone oxidation and electrochemical technology, applied in the field of water treatment, can solve problems such as low treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

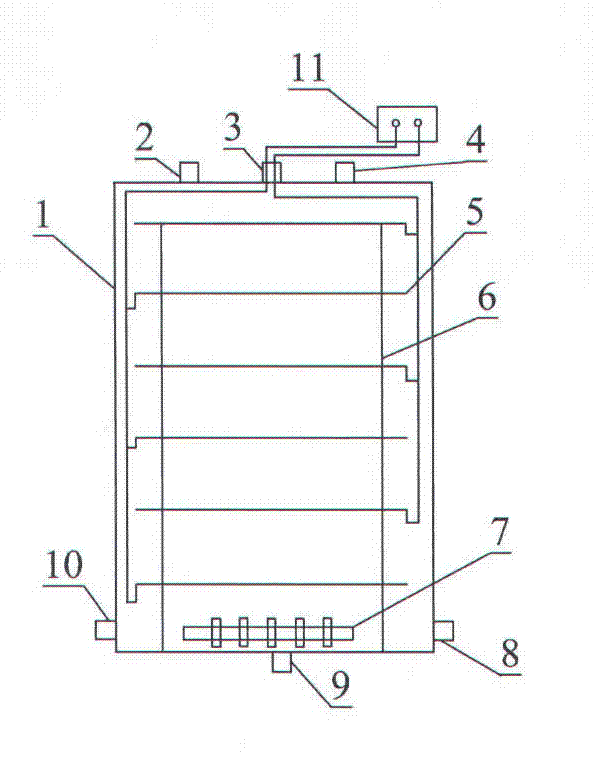

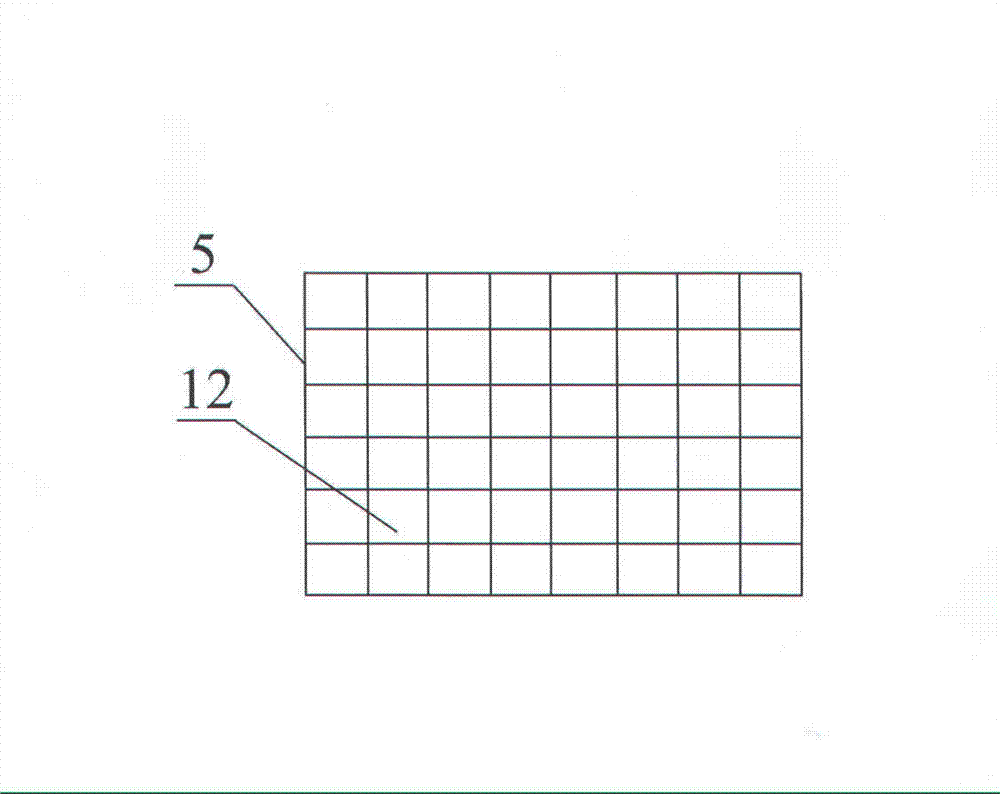

[0025] First of all, the processing device is made: a box body 1 of 400×400×400mm square is made of glass fiber reinforced plastic material, and a water inlet 2, a power line inlet 3 and a pressure relief port 4 are respectively arranged on the top of the box body 1, and a discharge port is provided at the bottom of the box body 1. The feed port 9, the two sides of the box body 1 are respectively provided with a water outlet 8 and an ozone air inlet 10, and the electrode plates 5 arranged equally are fixed by the nuts on the support column 6 in the box body 1, and the distance between the electrode plates 5 is 10mm, adjusted by the nut on the support column 6, the power line in the electrode plate 5 is a copper wire with an insulating layer, connected to the electrochemical power supply 11 through the power line inlet 3, and the power line in the electrode plate 5 is staggered up and down Connect the positive pole and the negative pole of the electrochemical power supply 11 in ...

Embodiment 2

[0028] Firstly, the processing device is made: a cylindrical box 1 with Φ=500 mm and a height of H=600 mm is made of glass fiber reinforced plastic material, and the top of the box 1 is respectively provided with a water inlet 2, a power line inlet 3 and a pressure relief port 4, The bottom of the box body 1 is provided with a discharge port 9, and the two sides of the box body 1 are respectively provided with a water outlet 8 and an ozone air inlet 10. In the box body 1, the evenly arranged electrode plates 5 are fixed by nuts on the support column 6, The distance between the electrode plates 5 is 50mm, which is adjusted by the nuts on the support columns 6. The power line in the electrode plates 5 is a copper wire with an insulating layer, which is connected to the electrochemical power supply 11 through the power line inlet 3, and the electrode plates 5 The power line in the battery is connected to the positive pole and the negative pole of the electrochemical power supply 1...

Embodiment 3

[0031] First of all, the processing device is made: a box body 1 of 200×200×200mm square is made of glass fiber reinforced plastic material, and a water inlet 2, a power line inlet 3 and a pressure relief port 4 are respectively arranged on the top of the box body 1, and a discharge port is provided at the bottom of the box body 1. The feed port 9, the two sides of the box body 1 are respectively provided with a water outlet 8 and an ozone air inlet 10, and the electrode plates 5 arranged equally are fixed by the nuts on the support column 6 in the box body 1, and the distance between the electrode plates 5 is It is 100mm, adjusted by the nut on the supporting column 6, the power line in the electrode plate 5 is a copper wire with an insulation layer, connected to the electrochemical power supply 11 through the power line inlet 3, and the power line in the electrode plate 5 is staggered up and down Connect the positive and negative poles of the electrochemical power supply 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com