Coal ash catch, storage and delivery system

A conveying system and storage technology, applied in the field of coal ash capture storage conveying system, can solve problems such as poor dust removal efficiency, pollutant leakage, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

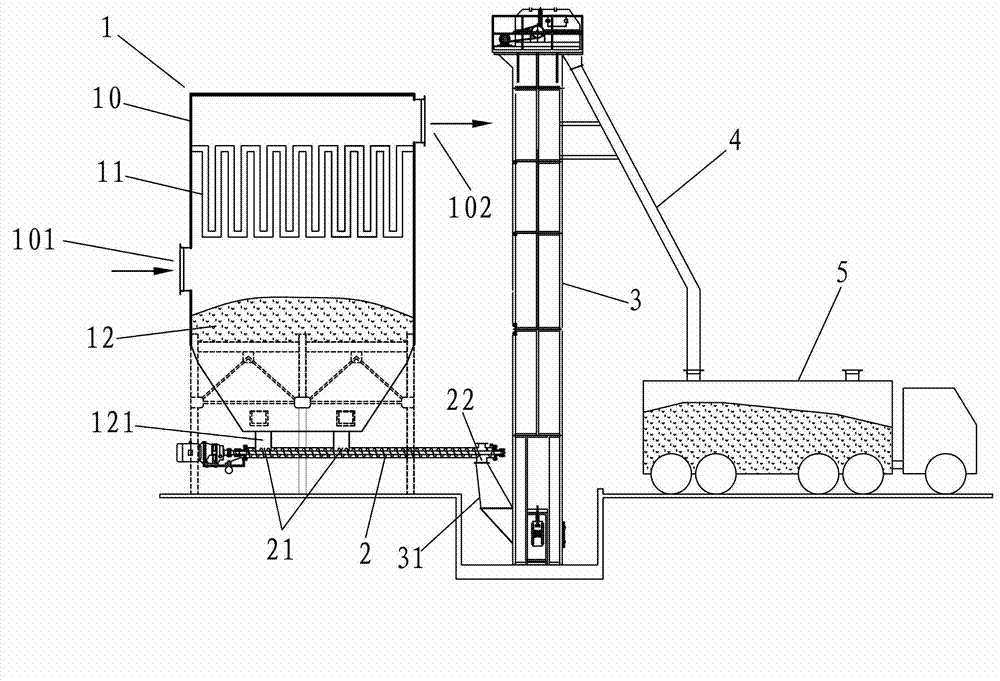

[0019] In this case, a coal ash capture storage and transportation system, such as figure 1 As shown, it includes a high-efficiency bag dust removal mechanism 1, a screw conveying mechanism 2, a lifting conveying mechanism 3, an ash conveying pipe 4 and a powder tank conveying mechanism 5, and these mechanisms are mutually hermetically assembled in one body.

[0020] The high-efficiency bag dust removal mechanism 1 includes an airtight casing 10, a high-efficiency dust collector 11 and an ash storage bin 12 installed up and down in the airtight casing 10, and the airtight casing 10 is provided with a flue gas inlet and outlet. Gas inlet 101 and flue gas outlet 102, the flue gas inlet 101 is located on the airtight casing 10 corresponding to the position between the high-efficiency dust collector 11 and the ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com