Automobile hub polishing method and device

A technology for automobile wheels and polishing devices, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., to achieve the effects of improving surface quality, increasing rolling force, and refining surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

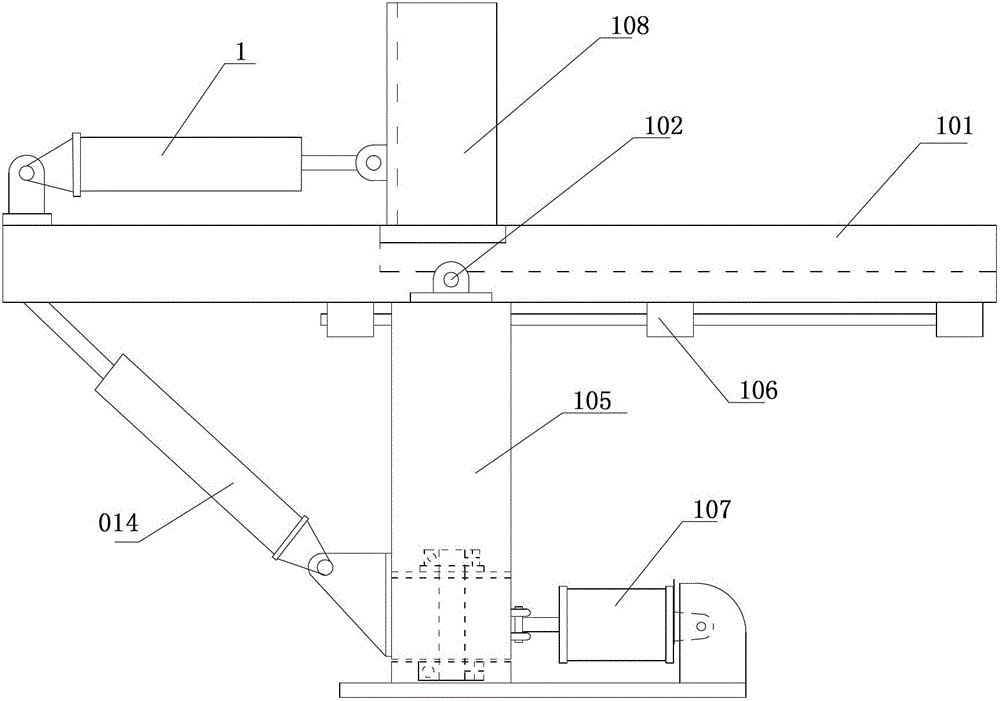

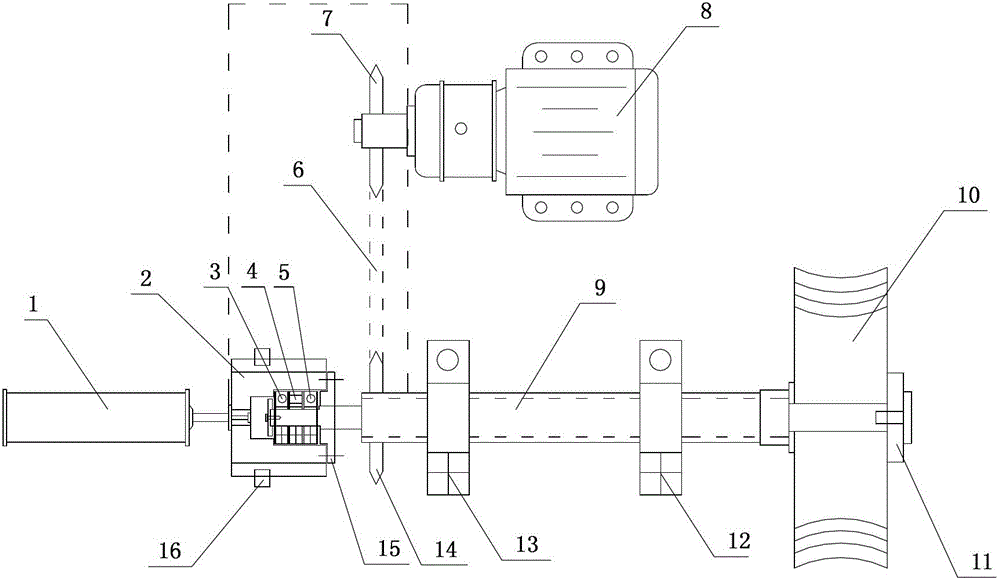

[0025] Example. A kind of automobile wheel hub polishing method, comprises the following steps:

[0026] ①Put white corundum balls of Ф1~2mm in the drum as abrasives, and the rotating shaft of the drum is perpendicular to the ground;

[0027] ② Clamp the car hub on the main shaft, and set the main shaft and the rotating shaft of the drum to cross;

[0028] ③Turn the drum and the main shaft at the same time for polishing;

[0029] ④ Replace the white corundum ball abrasive in the drum with white high-alumina ceramic ball abrasive, and continue to rotate the drum and spindle for polishing;

[0030] ⑤Remove the car hub and put it in the designated place for cleaning.

[0031] The spindle is at 60° to the axis of rotation of the drum.

[0032] The rotation speed of the main shaft is 0-50 rpm; the rotation speed of the drum is 12 rpm.

[0033] The rotation time of the step ③ and the step ④ are both 10-15 minutes.

[0034] Add water, cleaning agent and brightener to the white ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com