Piezoelectric on-off valve type jetting dispensing head

A technology of piezoelectric switch and injection point, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of time-consuming, re-centering, and only two pieces of piezoelectric ceramics with exactly the same size can be used. Achieve the effect of small nozzle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

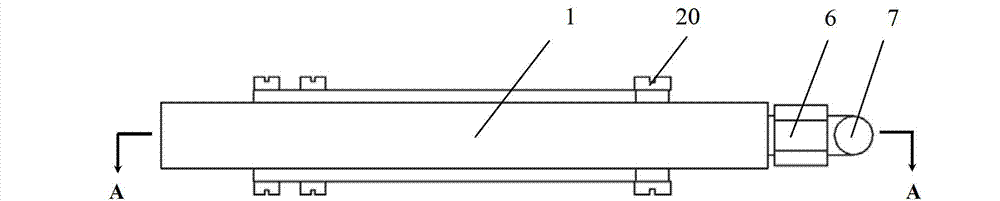

[0015] see Figure 2-5 , the embodiment of the present invention is provided with substrate 1, piezoelectric ceramics 2, pull rod 3, triangular block 5, heating block 11, block 13, nozzle 14, striker 16, flexible hinge 21 and liquid supply device; The substrate 1 is provided with In the flexible hinge 21, two piezoelectric ceramics 2 are respectively pre-tightened on the two arms of the flexible hinge 21 through a stopper 13. The front end of each piezoelectric ceramic 2 is respectively provided with a stopper 13, and the stopper 13 is fixed by a pull rod 3 on the two arms of the flexible hinge 21. On the base 1 and embedded in the block guide groove 12 on the edge of the inner frame of the base 1, the nozzle 14 is fixed on the lower front end of the base 1 through the nozzle fixing bolt 15, and has screw holes that can fix different forms of external nozzles. Both sides of base body 1 are provided with cover plate 19 respectively, and the rear ends of 2 cover plates 19 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com