A bonding machine device and a bonding alignment method

A bonding machine and bonding technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low alignment, long alignment time, and low image sensor yield, and achieve improved Yield, time reduction, and the effect of precise alignment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

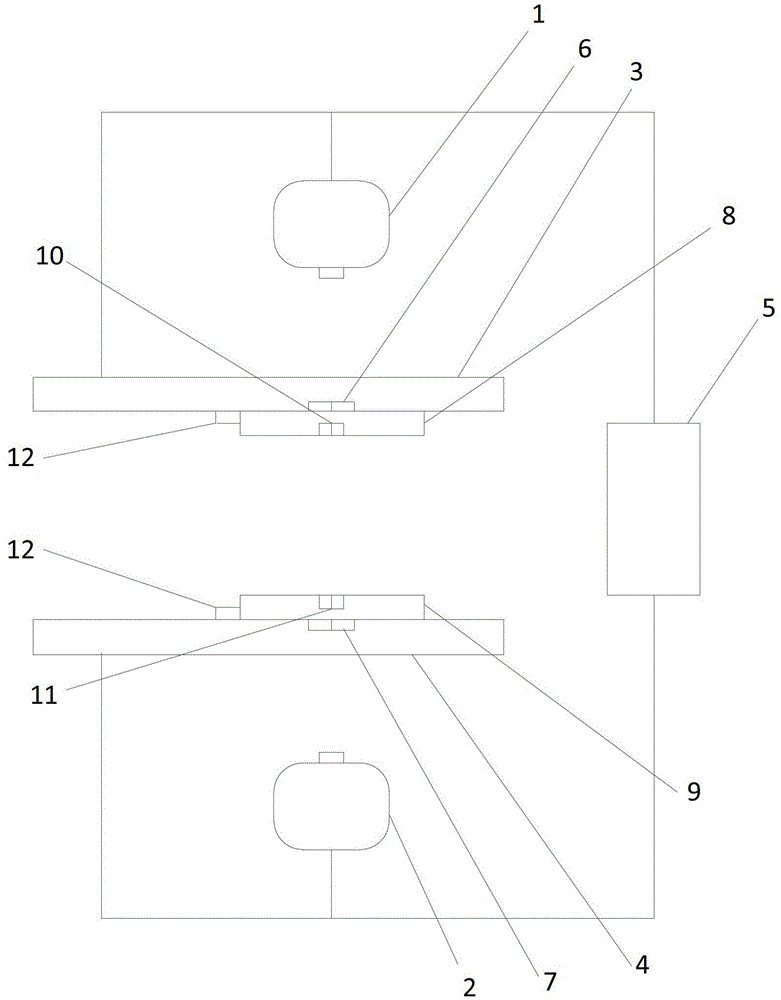

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

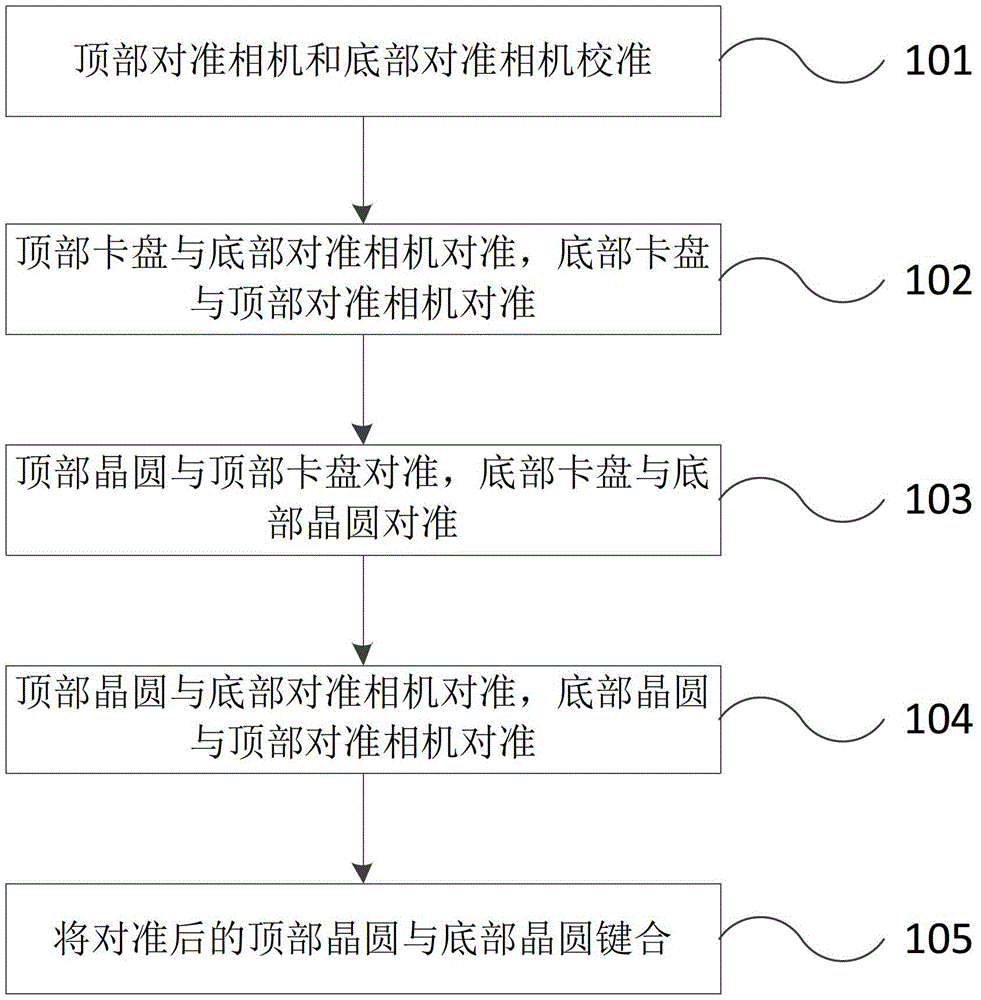

[0031] Such as figure 1 Shown, be the method flowchart of the present invention, its concrete steps are as follows:

[0032] Step 101, aligning the top alignment camera on the bonding machine table with the standard alignment mark on the bonding machine table, and aligning the bottom alignment camera with the standard alignment mark on the bonding machine table;

[0033] Step 102, move the top chuck on the bonding machine table to align the top chuck alignment mark provided on the top chuck with the bottom alignment camera, and move the bottom chuck on the bonding machine table to align the top chuck alignment mark provided on the top chuck with the bottom alignment camera. The bottom chuck alignment mark provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com