Large-scale coal-fired boiler smoke gas flow rate soft measuring method

A flue gas flow, coal-fired boiler technology, applied in the field of boilers, can solve problems such as difficult to find front and rear straight pipe sections, corrosion measuring devices, fly ash clogging, etc., to save equipment and human resources, fast dynamic response, and accurate measurement. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

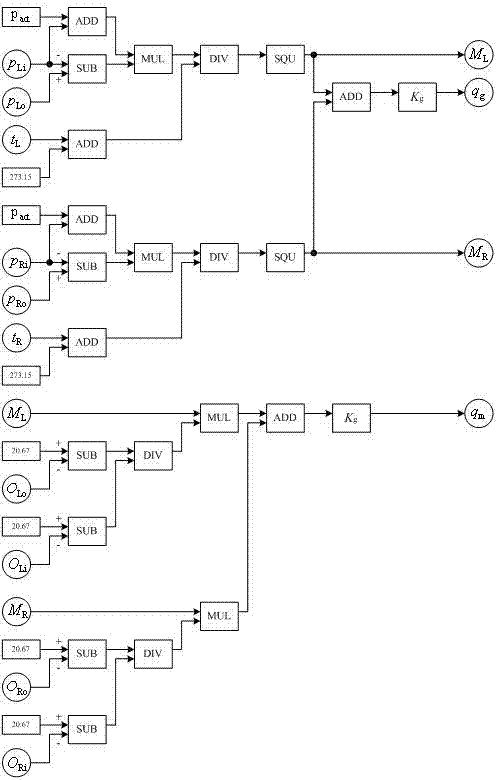

[0031] The present invention carries out according to the following steps:

[0032] (1) Flue gas flow calculation

[0033] The formula for calculating the flue gas flow at the outlet of the induced draft fan is:

[0034] (1)

[0035] in: q g is the flue gas flow rate at the outlet of the induced draft fan (Nm 3 / s); K g is the discharge coefficient (dimensionless); M L is the flue gas flow variable in the p.u. left flue (Nm 3 / s); M R is the flue gas flow variable in the p.u. right flue (Nm 3 / s).

[0036] The formula for calculating the flue gas flow at the outlet of the economizer is:

[0037] (2)

[0038] in: q m is the flue gas flow rate at the outlet of the economizer (Nm 3 / s); O Li Oxygen content of the flue gas before the left air preheater (%); O Lo Oxygen content of the flue gas after the left air preheater (%); O Ri Oxygen content of the flue gas before the air preheater on the right side (%); O Ro It is the flue gas oxygen conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com