Parallel flow evaporator

An evaporator and parallel flow technology, which is applied in the direction of evaporator/condenser, heat exchanger shell, heat exchange equipment, etc., can solve the problems of not being able to guarantee the same flow rate into each pipeline and affecting the heat exchange effect, and achieve reduction Dissipation of energy, uniform flow, and the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

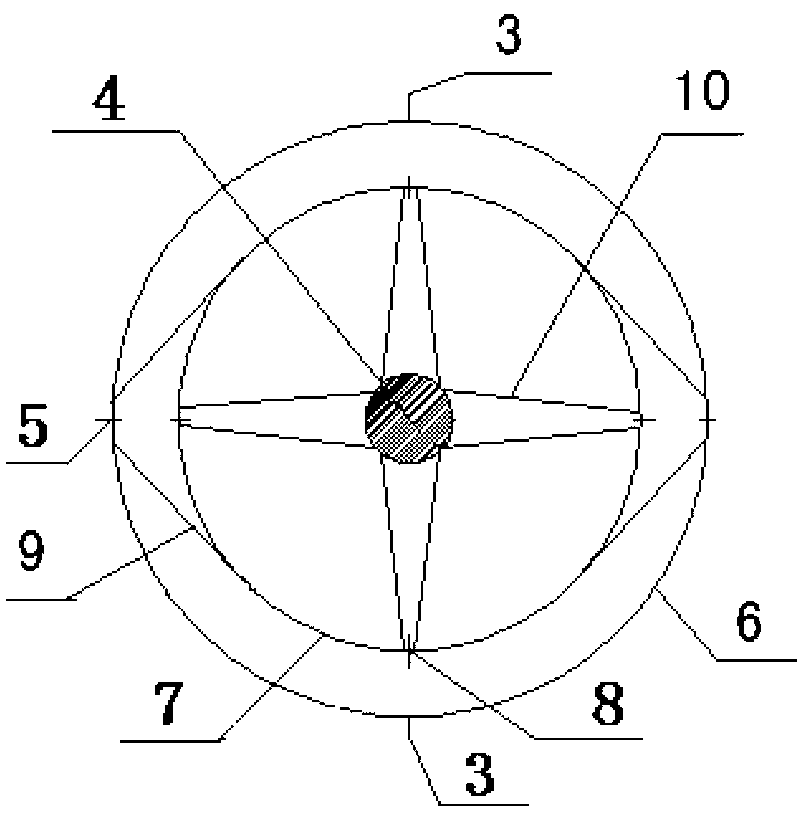

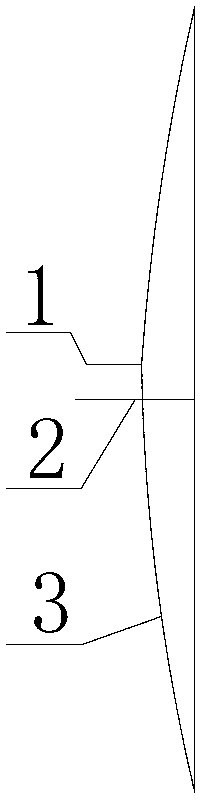

[0017] The schematic diagram of parallel flow evaporator of the present invention is as figure 1 , figure 2 As shown, it includes a liquid distributor 4, an inner circular evaporation tube 7, an outer circular evaporation tube 6, a plurality of first evaporation tubes 10, and a plurality of second evaporation tubes 9. The liquid distributor 4 is disc-shaped, The disk-shaped center of the liquid distributor 4 is provided with a liquid inlet, and the disk-shaped edge of the liquid distributor 4 is provided with a plurality of symmetrical liquid outlets. The liquid inlet of the liquid distributor 4 A liquid inlet pipe 2 is installed on the mouth, and each of the first evaporation pipes 10 is connected between the liquid outlet of the liquid distributor 4 and the liquid inlet on the inner circular evaporation pipe 7. The second evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com