Luminaire mounting mechanism and recessed luminaire including the mechanism

A lamp installation and mounting board technology, which is applied to the components of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of poor adaptability of mounting holes, weakened elasticity and falling off of shrapnel devices, and achieve long service life and wide application range The effect of wide and strong support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments.

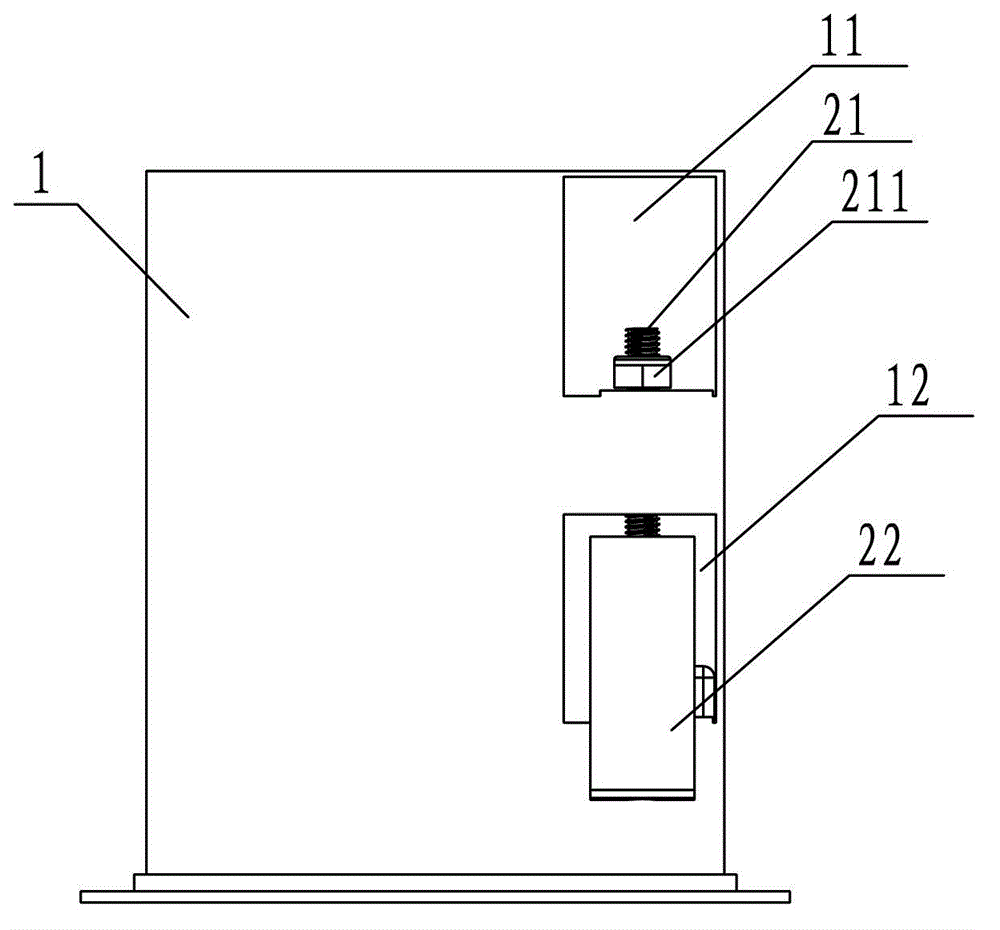

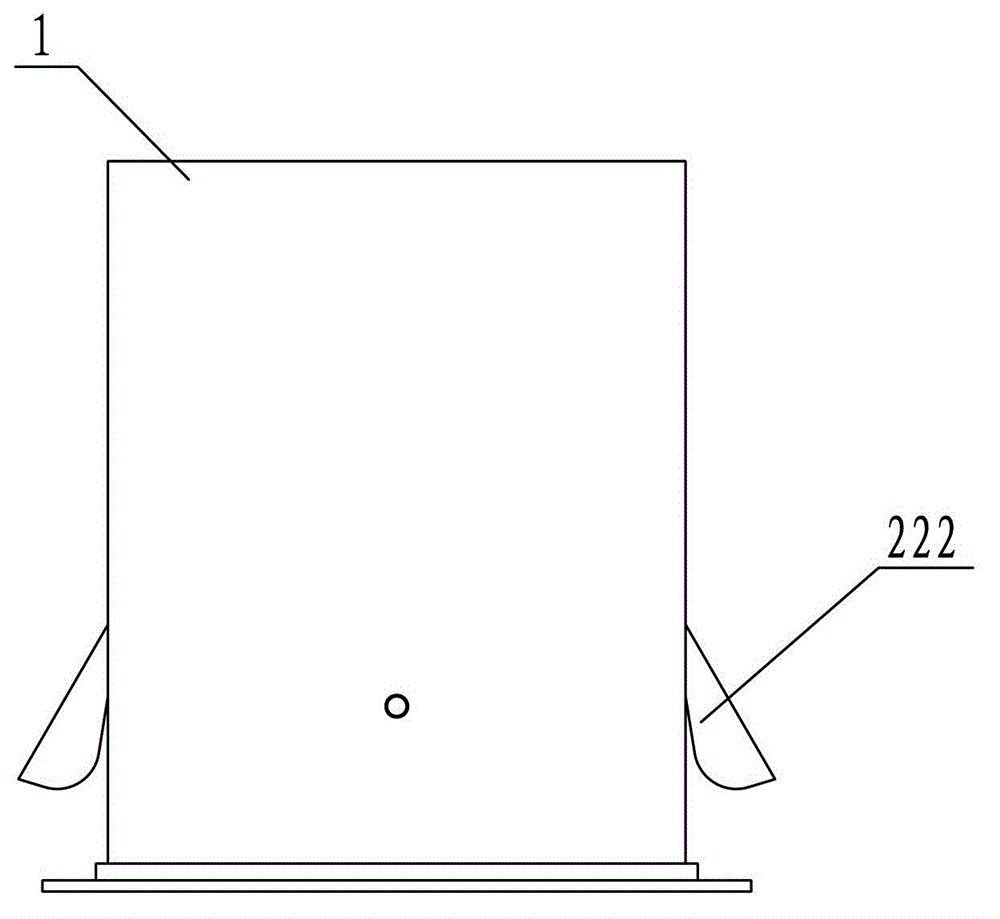

[0021] refer to Figure 1 to Figure 6 As shown, a lamp installation mechanism includes a lampshade 1 and a clamping device 2 installed on the lampshade 1 .

[0022] The left and right sides of the lampshade 1 are respectively provided with vertically arranged upper through holes 11 and lower through holes 12, and the lower edges of the upper through holes 11 and the lower through holes 12 are respectively formed with an upper mounting plate 13 extending inwardly. and the lower mounting plate 14, and the upper mounting plate 13 and the lower mounting plate 14 have mounting holes respectively. The clamping device 2 includes a screw rod 21, a supporting part 22, a transmission shaft 23, and a stopper 24. The screw rod 21 is vertically installed in the lampshade 1, and the supporting part 22 is injection-molded at one time. One end is a connecting part 221, and the other end is a supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com