A steel plate high-strength concrete composite connecting beam

A high-strength concrete and concrete technology, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve problems such as concrete compression damage, avoid exposure of cracks, expand the scope of work, and facilitate and fast construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

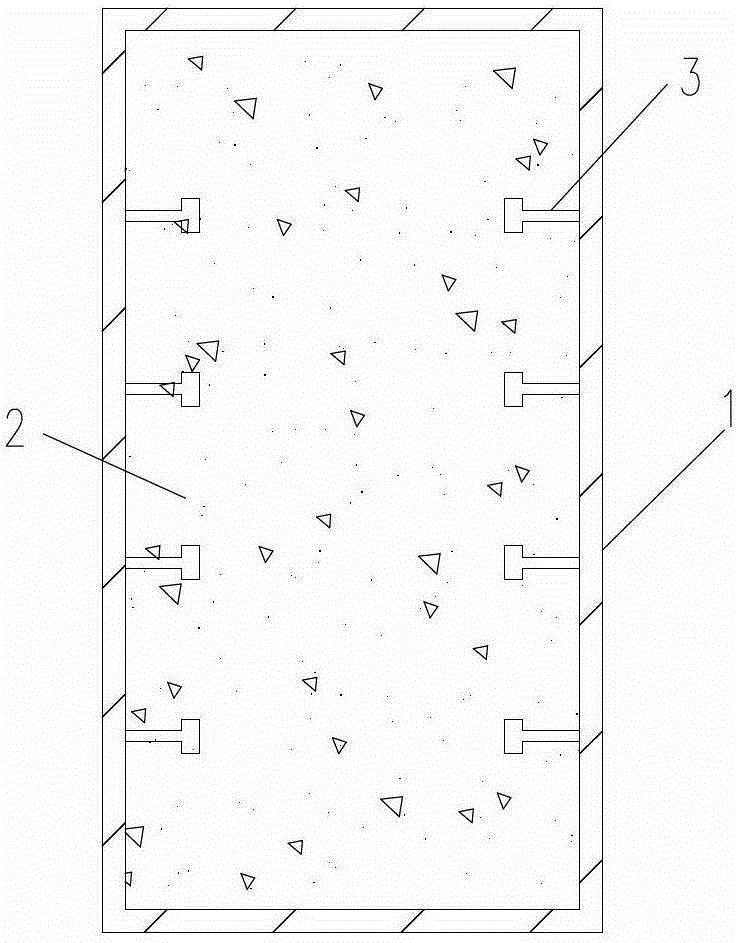

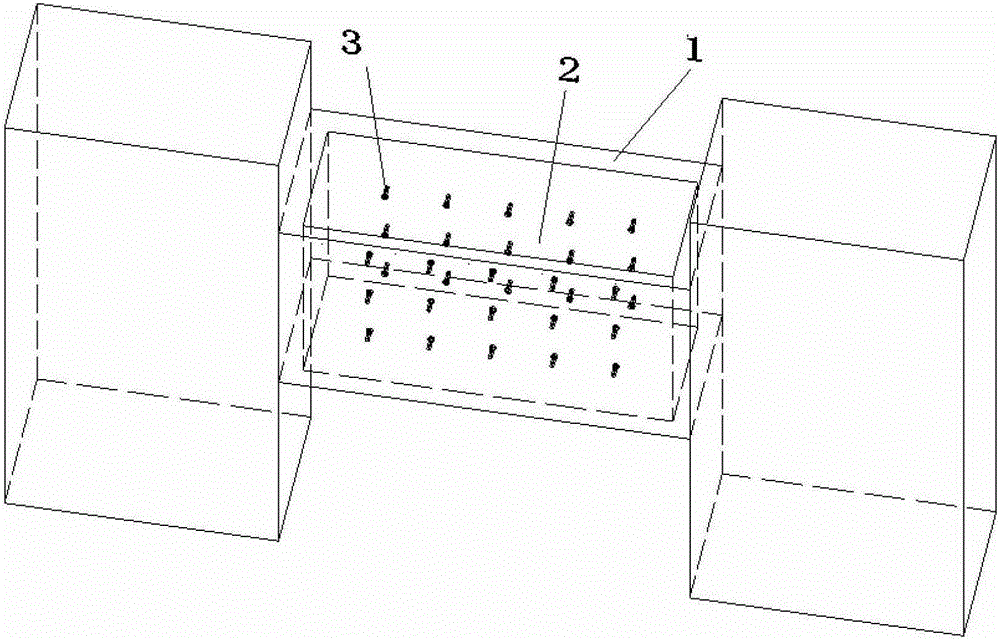

[0021] A new type of steel-concrete composite coupling beam with steel plates set on both sides, that is, the outer steel plate-concrete composite coupling beam, the concrete coupling beam is poured inside the outer steel plate, and the concrete and the steel plate are strengthened by studs. The studs are welded on the inner side of the double-layer steel plate, perpendicular to the steel plate, and arranged in several rows evenly along the height direction of the steel plate. The outer covering steel plate is enclosed by four steel plates on four sides to form an outer covering formwork, and the concrete is wrapped in the covering formwork. The concrete adopts high-strength concrete (above C6).

[0022] This new type of composite coupling beam provides flexural strength and shear strength by arranging steel plates on the outside of the coupling beam instead of closely matched longitudinal and transverse steel bars, which is beneficial to exert the ductility of the structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com