Method for preparing calcium sulfate whisker through recrystallization

A calcium sulfate whisker, recrystallization technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve the problems of difficult industrial application and high cost, achieve resource utilization, easy The effect of low operating, investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

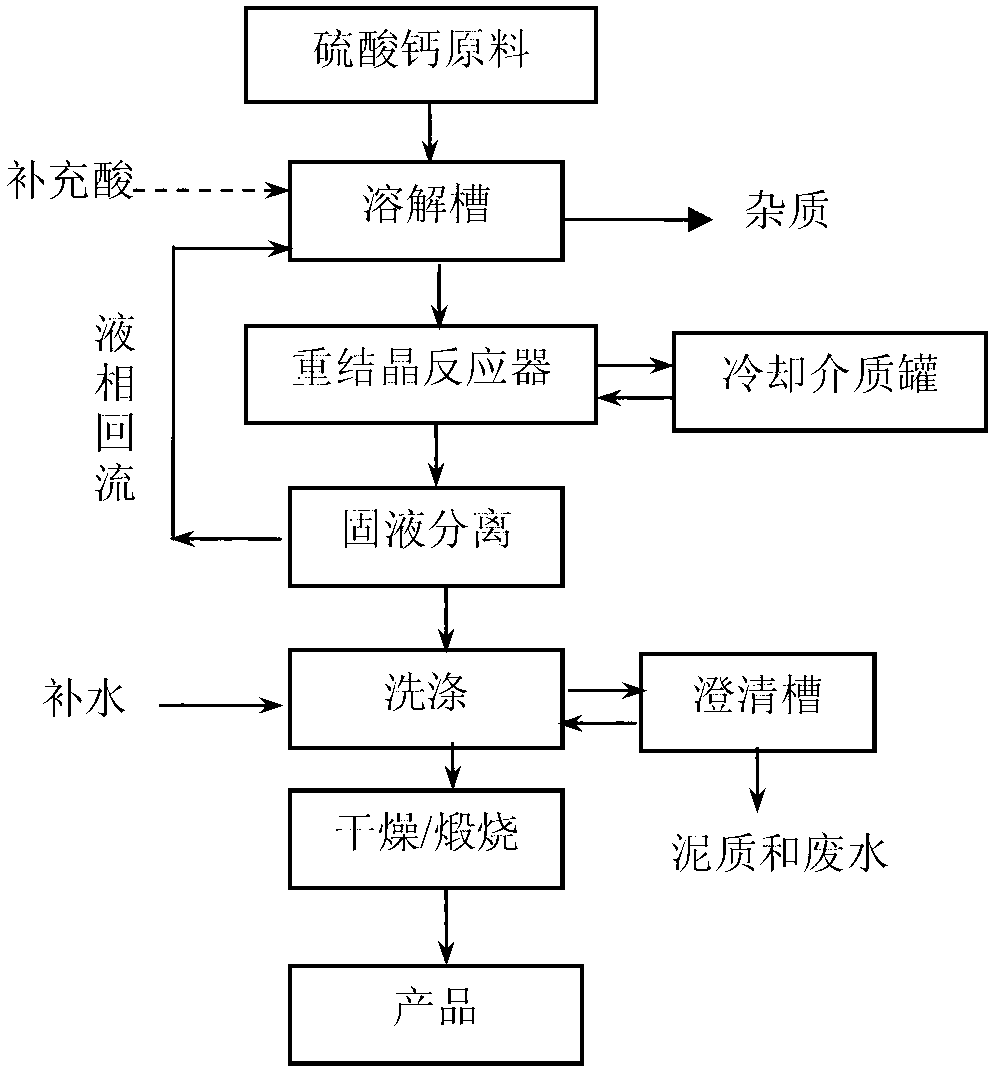

Method used

Image

Examples

Embodiment 1

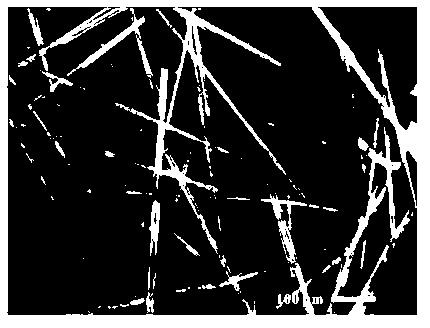

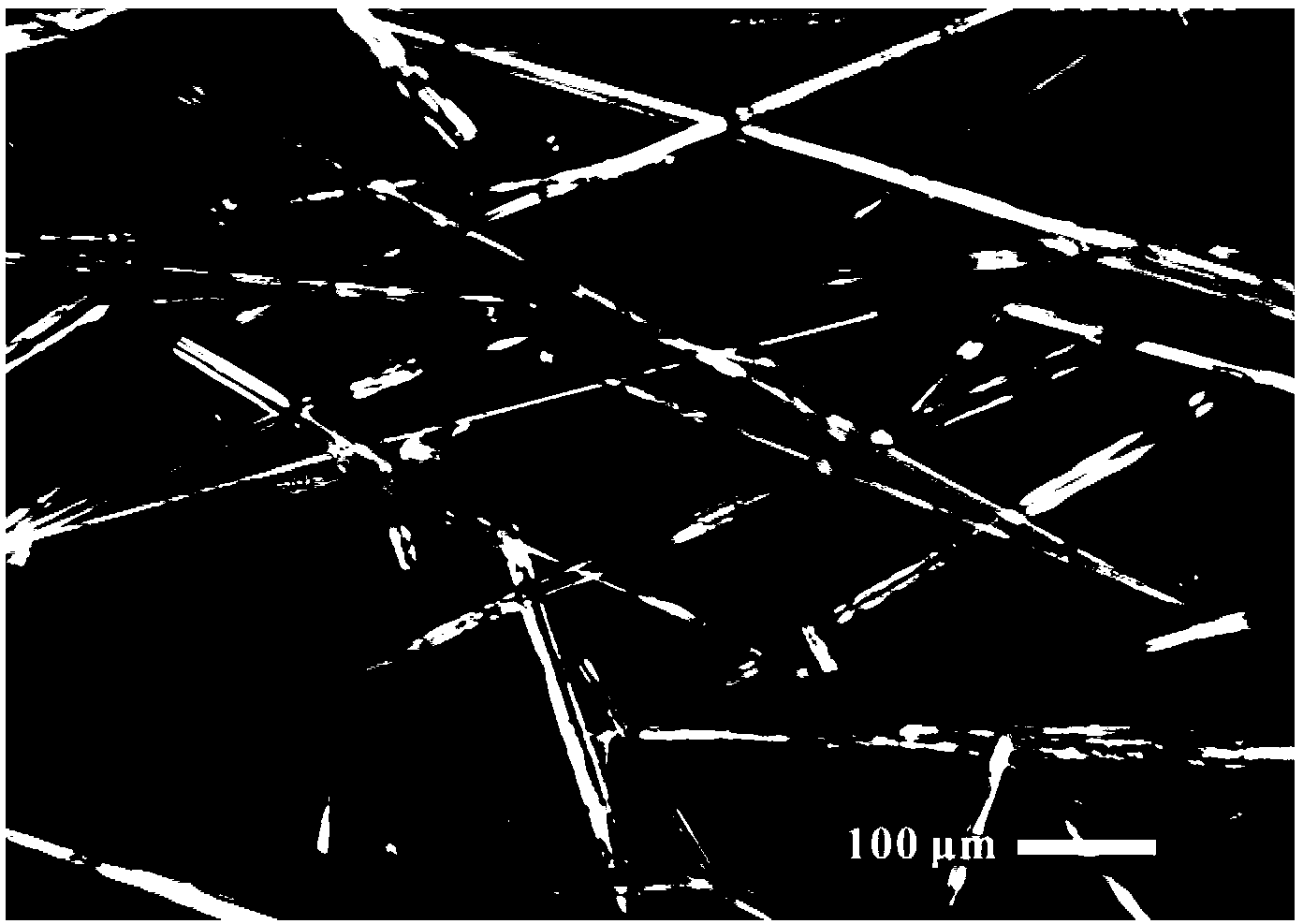

[0032] Add 110g of calcium sulfate dihydrate reagent to 1L of sulfuric acid solution with a mass percentage concentration of 14%, stir evenly, and at the same time heat to 85°C at a rate of 1.5K / min to dissolve, then stand still, and adjust the jacket cold air through the PID control system The flow rate of the suspension is reduced to 20°C at an average rate of 0.5K / min, and the temperature is maintained for 0.5h. The product is filtered and washed with water, and then dried at 60°C for 1h to obtain an aspect ratio of 50. Calcium sulfate dihydrate whiskers at ~110.

Embodiment 2

[0034] Add 6kg of gypsum ore (calcium sulfate content ≥70%) with a particle size of ≤3cm into a tank filled with 200L of sulfuric acid solution with a concentration of 25% by mass and stir, while heating at a rate of 2.0K / min to 90°C to dissolve and then reduce Stirring strength or standing still; pump the upper suspension into the crystallization reactor for stirring, adjust the flow rate of the jacket cold air through the PID control system, so that the temperature of the suspension drops to 20°C at an average rate of 1.0K / min, and maintain the temperature Aging for 1 hour; filter the product through vacuum, and wash with water to meet the quality requirements; put the separated solid phase product in an oven and dry at 60°C for 1 hour to obtain calcium sulfate dihydrate whiskers with an aspect ratio of 50~110 .

Embodiment 3

[0036] Add 1kg of desulfurized gypsum into a tank containing 100L of sulfuric acid solution with a mass percentage concentration of 35%, stir evenly, and at the same time, heat at a rate of 0.5K / min to 75°C to dissolve and let it stand; pump the upper suspension into the crystallization reactor Stir, adjust the flow of cold water in the jacket through the PID control system, reduce the temperature of the suspension to 20°C at an average rate of 1.5K / min, and keep the temperature for aging for 0.5h, filter the product and wash it with water, and then cool it at 60°C Drying for 1 hour under the hood to obtain calcium sulfate dihydrate whiskers with an aspect ratio of 50-180.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com