Production method of tire tread with low rolling resistance

A technology with low rolling resistance and manufacturing method, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve problems such as lack of good performance and inability to play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

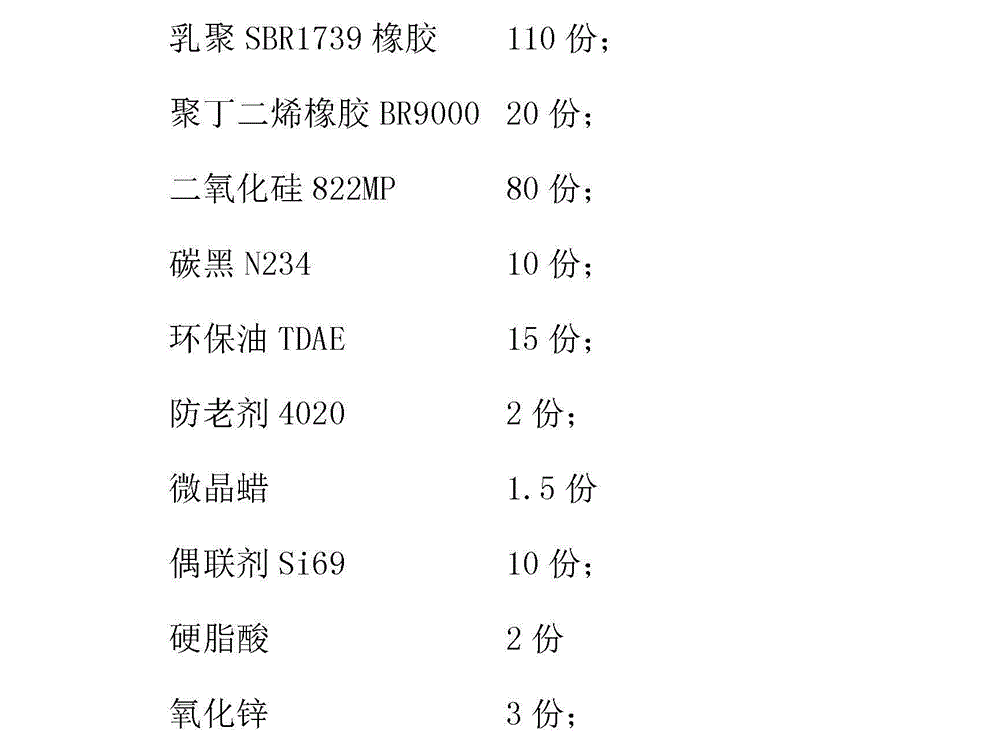

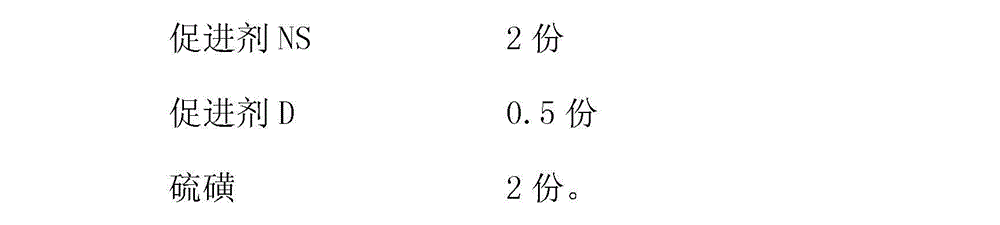

[0017] In order to facilitate the understanding of the present invention, the embodiments of the present invention are described below, and those skilled in the art should understand that the following description is only for the convenience of explaining the present invention, not as a specific limitation on its scope.

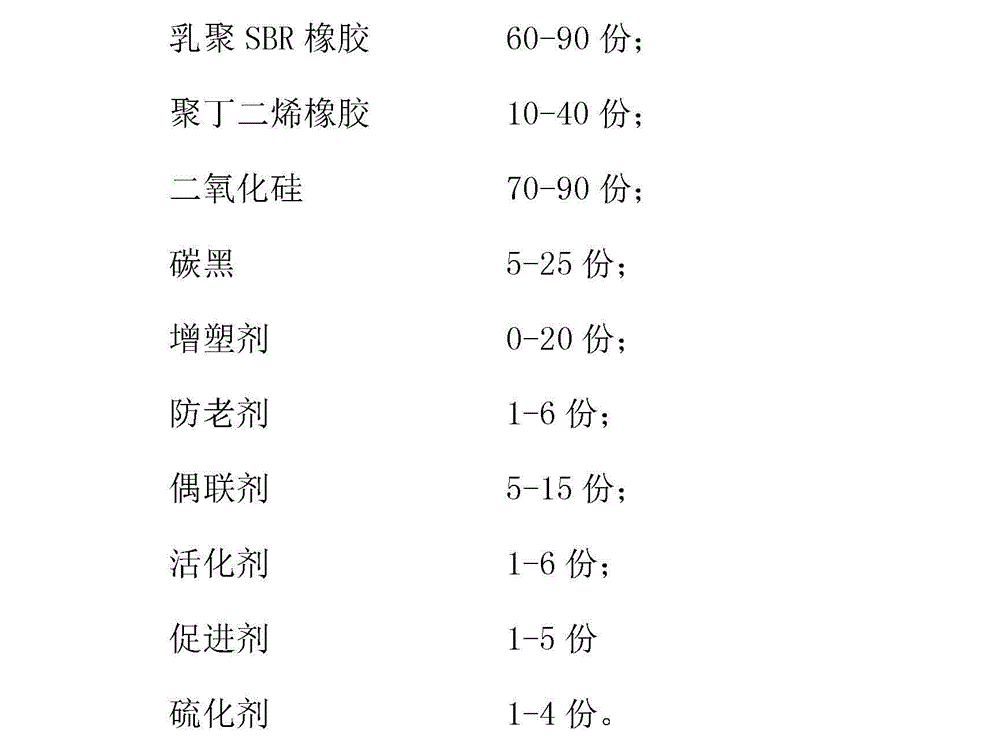

[0018] A rubber composition for radial passenger car tire tread, characterized in that its composition consists of the following components:

[0019]

[0020] Wherein, the said emulsion polystyrene butadiene rubber is mixed with one or more of the following elastomer materials: emulsion polystyrene butadiene rubber SBR1723, emulsion polystyrene butadiene rubber SBR1783, emulsion polystyrene butadiene rubber SBR1739, emulsion polystyrene butadiene rubber Rubber SBR1789, Emulsion Styrene Butadiene Rubber SBR1721, Emulsion Styrene Butadiene Rubber SBR1500, Emulsion Styrene Butadiene Rubber SBR1502;

[0021] The polybutadiene rubber is a mixture of one or more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com