Low-rolling-resistance tire tread rubber composition

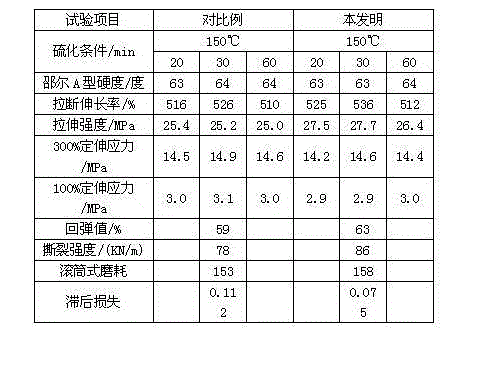

A rubber composition and technology of low rolling resistance, applied in the field of low rolling resistance tire tread rubber composition, can solve the problem of not very obvious effect, achieve unaffected wear resistance, improve tensile strength, and reduce hysteresis loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention will be further described:

[0024] The raw material components and content of the present invention can be prepared according to existing conventional techniques, and the concrete steps are:

[0025] The first stage of mixing: add natural rubber and butadiene rubber to the internal mixer GK400, press the bolt for 20 seconds, mix carbon black, white carbon black, zinc oxide, anti-aging agent 4020, anti-aging agent RD, silane coupling agent, Add protective wax to internal mixer GK400 at the same time, press the bolt for 30 seconds, lift the bolt, press the bolt to 125°C and lift the bolt, press the bolt again to 145°C and keep for 30 seconds, then discharge the glue, and thin pass twice on the open mill to remove the sheet.

[0026] The second stage of mixing: Add a section of mixed rubber, press the bolt for 35 seconds, lift the bolt and then press the bolt for 35 seconds, lift the bolt and press the bolt to 145...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com