Phosphatidylcholine high-temperature purification method

A technology for phosphatidylcholine and high-temperature purification, applied in the field of phospholipids, can solve the problems of difficulty in separation and purification of phosphatidylcholine, inconvenience in large-scale production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

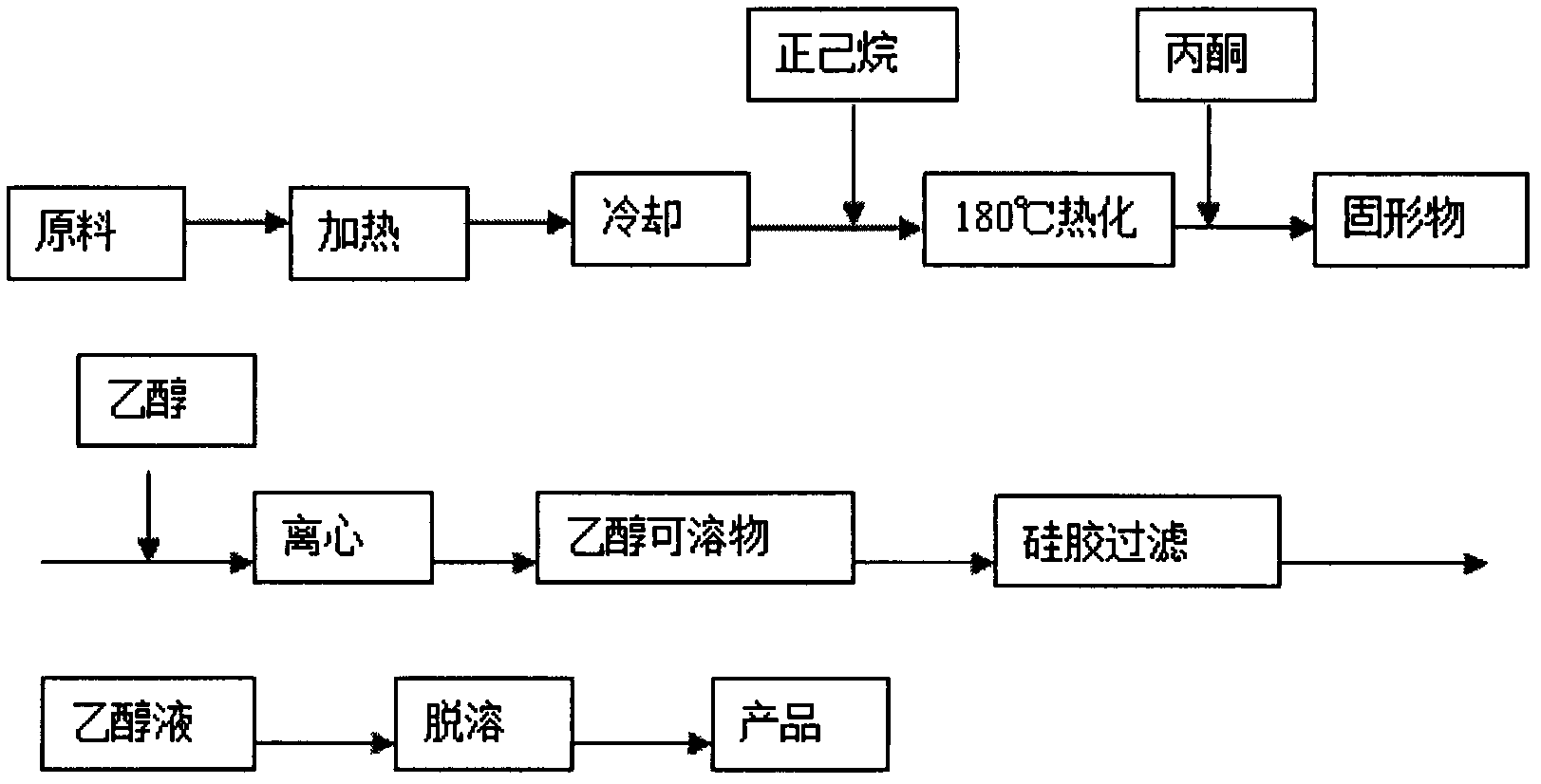

Method used

Image

Examples

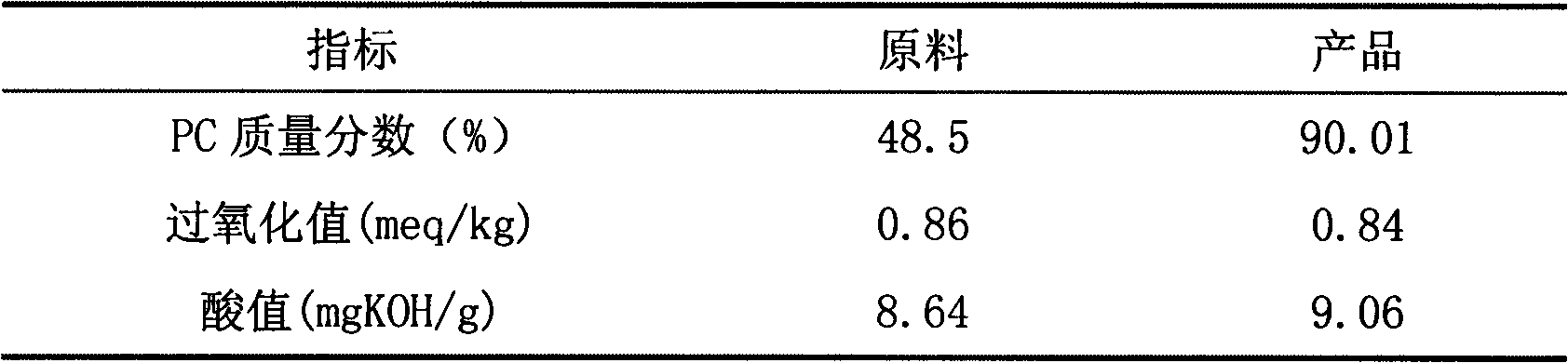

Embodiment 1

[0014] Accurately weigh 10 grams of alcohol-soluble phospholipid raw material, heat it at 100°C for 1 hour, dissolve it in 12 ml of n-hexane after cooling, vacuum rotary evaporation and thermalization in an oil bath at 180°C for 0.5 hour to obtain black phospholipid thermal product, phospholipid Add acetone to the heating material and wash until free of oil. The residue was dissolved in 20 ml of 85% ethanol, stirred for 10 minutes, and then centrifuged at 4500 rpm for 30 minutes to obtain ethanol-soluble matter. The ethanol soluble matter was added to a Buchner funnel covered with 10 g of silica gel, and eluted with 85% ethanol which was 5 times of the ethanol soluble matter, the ethanol solution was collected, and the ethanol was removed in vacuum to obtain a product with a phosphatidylcholine content of 90.01%.

Embodiment 2

[0016] Accurately weigh 10 grams of alcohol-soluble phospholipid raw material, heat it at 100°C for 1 hour, dissolve it in 12 ml of n-hexane after cooling, and vacuum rotary evaporation and thermalization in an oil bath at 180°C for 1 hour to obtain black phospholipid thermal product; phospholipid Add acetone to the heating material and wash until free of oil. The residue was dissolved in 20 ml of 85% ethanol, stirred for 10 minutes, and then centrifuged at 4500 rpm for 30 minutes to obtain ethanol-soluble matter. The ethanol soluble matter was added to a Buchner funnel covered with 20 grams of silica gel, and eluted with 85% ethanol which was 10 times of the ethanol soluble matter, and the ethanol solution was collected, and the ethanol was removed in vacuum to obtain a product with a phosphatidylcholine content of 88.6%.

Embodiment 3

[0018] Accurately weigh 10 grams of alcohol-soluble phospholipid raw material, heat it at 100°C for 1 hour, dissolve it in 12 ml of n-hexane after cooling, vacuum rotary evaporation and thermalization in an oil bath at 180°C for 0.5 hour to obtain black phospholipid thermal product; phospholipid Add acetone to the heating material and wash until free of oil. The residue was dissolved in 20 ml of 85% ethanol, stirred for 10 minutes, and then centrifuged at 4500 rpm for 30 minutes to obtain ethanol-soluble matter. The ethanol soluble matter was added to a Buchner funnel covered with 20 grams of silica gel, and eluted with 85% ethanol which was 5 times of the ethanol soluble matter, the ethanol solution was collected, and the ethanol was removed in vacuum to obtain a product with a phosphatidylcholine content of 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com