Method for performing innocent treatment on carcasses

An animal carcass and processor technology, which is used in animal carcass fertilizer, biological organic part treatment, climate change adaptation, etc. Low cost and operating cost, scientifically and rationally conceived effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

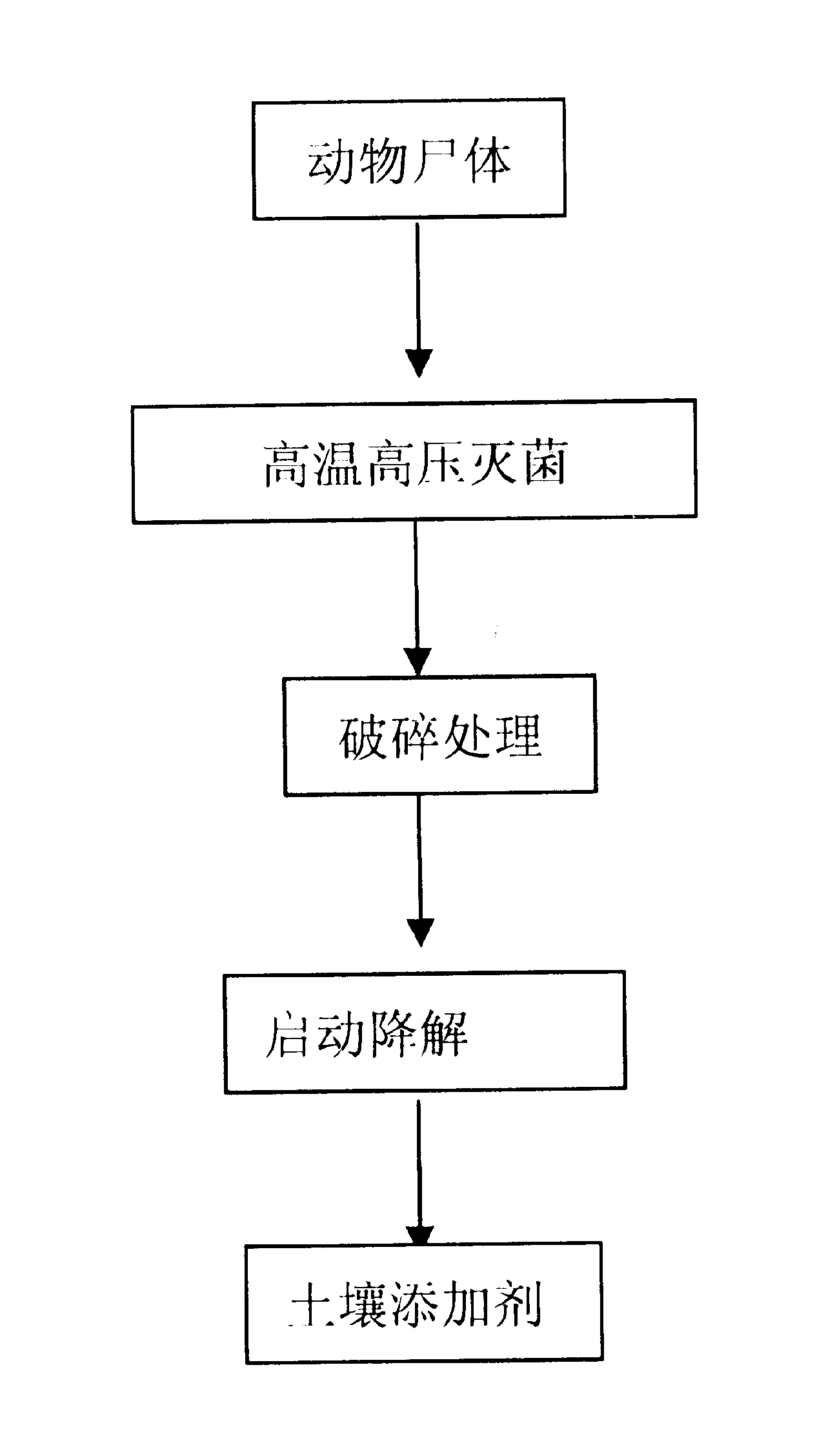

Image

Examples

Embodiment 1

[0022] (1) High-temperature sterilization: put the diseased animal carcasses (tissues) whole and in batches into a closed sterilization processor, set the temperature at 180°C, and the pressure at 5kg / cm 2 , the sterilization treatment time is 6 hours, which can effectively kill pathogenic microorganisms;

[0023] (2) Crushing treatment: the animal carcass tissue that has been sterilized and matured by high temperature is transferred to the crushing processor and crushed into fine particles of about 30mm.

[0024] (3) Start degradation: transfer the above broken materials into a horizontal drum degradation reactor, and add auxiliary materials in proportion, including sawdust, straw, rice bran, corncobs, branches and other by-products of crops, one or several mixtures. Add biological complex bacteria degradation agent. Start the drum degradation reactor to work, maintain the working temperature at 55°C-80°C, and the humidity at 40-60%. After working for 120 hours, the drum wil...

Embodiment 2

[0026] (1) High-temperature sterilization: Put the diseased animal carcasses (tissues) whole and in batches into a closed sterilization processor, set the temperature at 250°C, and the pressure at 5kg / cm 2 , the sterilization treatment time is 4 hours, which can effectively kill pathogenic microorganisms;

[0027] (2) Crushing treatment: the animal carcass tissue that has been sterilized and matured by high temperature is transferred to a crushing processor to be crushed into fine particles of about 20mm.

[0028] (3) Start degradation: transfer the above broken materials into a horizontal drum degradation reactor, and add auxiliary materials in proportion, including sawdust, straw, rice bran, corncobs, branches and other by-products of crops, one or several mixtures. Add biological complex bacteria degradation agent. Start the drum degradation reactor to work, maintain the working temperature at 60°C-80°C, and the humidity at 45-55%. After working for 120 hours, the drum wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com