Front-mounted hydraulic cylinder lifting mechanism for light and medium-duty dump trucks

A technology of lifting mechanism and dump truck, which is applied in the direction of inclined load-carrying vehicles, etc. It can solve the problems of installation accessories and large installation space, high strength requirements of the lifting mechanism, and affecting the service life of the oil cylinder, so as to shorten the loading time , Ensure safety and stability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

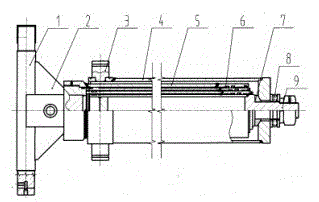

[0012] Example 1, such as figure 1 As shown, the purpose of the present invention is achieved through the following technical solutions. The present invention includes an outer protective cylinder 4, an outer cylinder 5, a movable ball joint 7, a piston rod 9, and an outer cylinder is provided with an oil inlet hole and a seal , which is characterized in that: it is also provided with a lower installation shaft 1, an upper installation shaft 3, a dirt receiving ring 6, and a reinforcement plate 2, the two ends of the lower installation shaft are connected with the frame, the middle part of the lower installation shaft is welded with a reinforcement plate, and the lower installation shaft is connected to the vehicle frame. The outer cylinder body is fastened and connected by threads, the upper mounting shaft is welded to the outer protective cylinder body, the two shaft ends of the upper mounting shaft are connected to the cargo box of the car, the movable ball hinge is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com