Device for cutting gel paste

A technology of cutting device and gel paste, which is applied in the direction of metal processing, etc., can solve the problems of high cost, waste of time and manpower, difficulty in controlling precision, etc., and achieve the effects of reducing production cost, improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

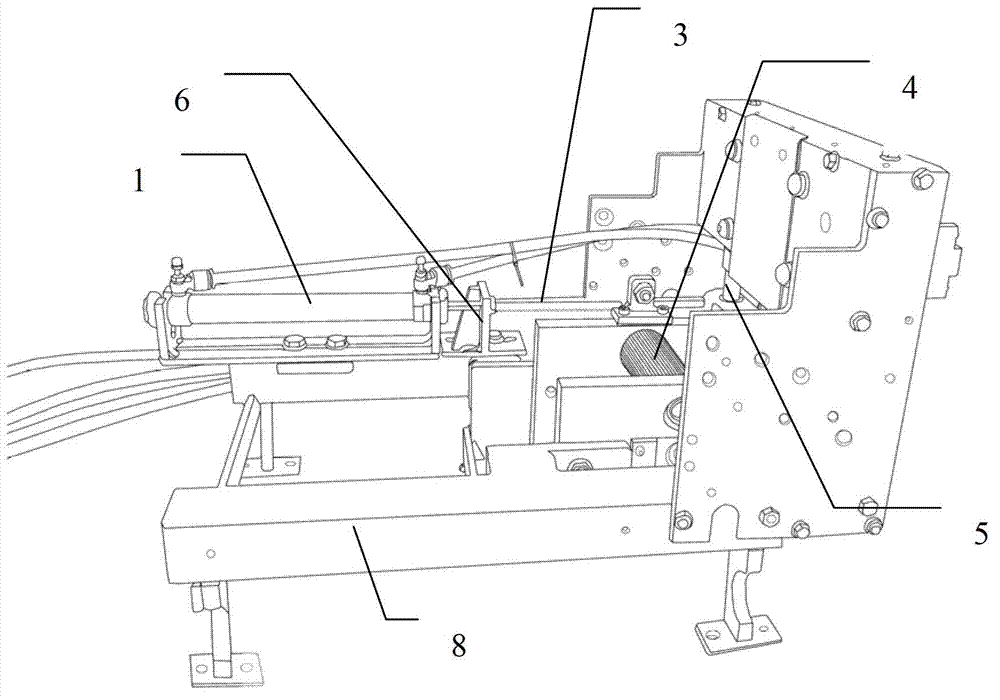

[0019] In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the drawings required in the description of the embodiments or the prior art will be briefly introduced below.

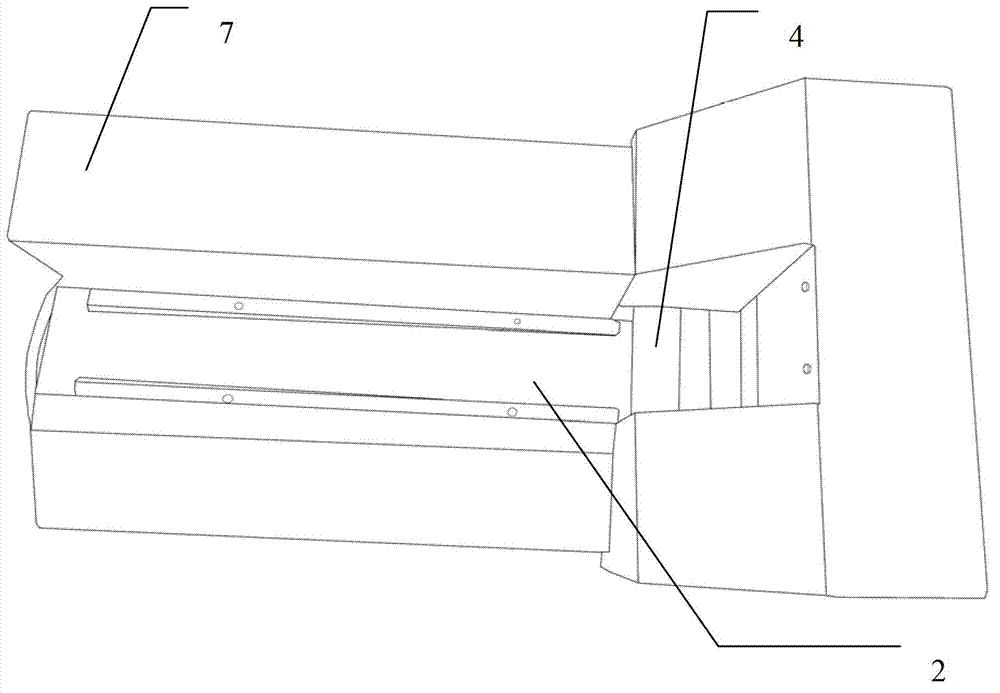

[0020] Such as figure 1 with figure 2 Shown, the invention provides a kind of cutting device of gel ointment, comprising:

[0021] The conveying device includes a first cylinder 1 and a conveying trough 2, the first cylinder is arranged on the second half of the guide rail 3, the lower surface of the first half of the guide rail is provided with gear teeth, and the front end of the conveying trough is provided with a cylinder Body rolling member 4, one side of the cylindrical rolling member is fixed with a flywheel (not shown in the figure), the flywheel is meshed with the front half of the guide rail through gear teeth, and the flywheel makes the gear teeth move forward Drive the cylindrical rolling member to rotate, and when the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com