Laser cutting head follow-up device

A technology of laser cutting head and follow-up device, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult assembly, inflexible movement of nozzle up and down, slow response, etc., to achieve consistent cutting and forming, improve cutting Quality and cutting efficiency, good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing

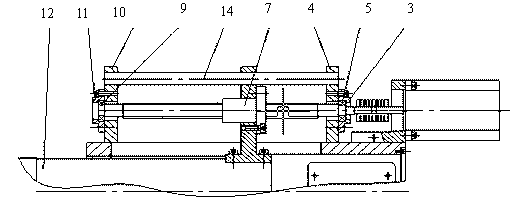

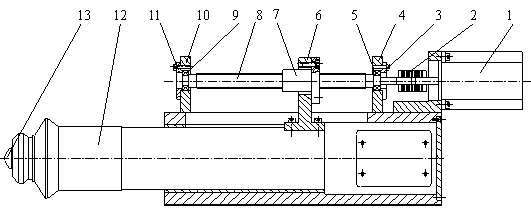

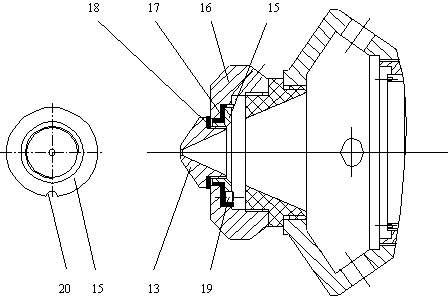

[0012] See attached figure 2 , image 3 , a laser cutting head servo device, including a stepping motor 1, a coupling 2, a bearing seat 3, a shaft end support 4, a rolling bearing 5, a nut seat 6, a ball screw nut 7, and a ball screw 8 , Rolling bearing two 9, shaft end support two 10, bearing seat two 11, sleeve 12, nozzle 13, the stepping motor 1 is connected with the ball screw 8 through the coupling 2, rolling bearing one 5 is through the shaft end support one 4 It is fixed on bearing seat 1 3, rolling bearing 2 9 is fixed on bearing seat 2 11 through shaft end support 2 10, said rolling bearing 1 5 and rolling bearing 2 9 are connected by ball screw 8, nut seat 6 and ball screw nut 7 The end faces are matched, and there is a gap in the radial direction. The front end of the sleeve 12 is provided with a nozzle 13. The nozzle 13 is isolated from the outside world through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com