Installation structure of grinding roller casing of roller type grinder

A technology for installing structure and grinding rollers, applied in grain processing and other directions, can solve the problems of inconvenient maintenance and installation, compression and explosion resistance, poor vibration and noise reduction, complex structure, etc., and achieves convenient maintenance, installation and disassembly, enhanced compression resistance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Example:

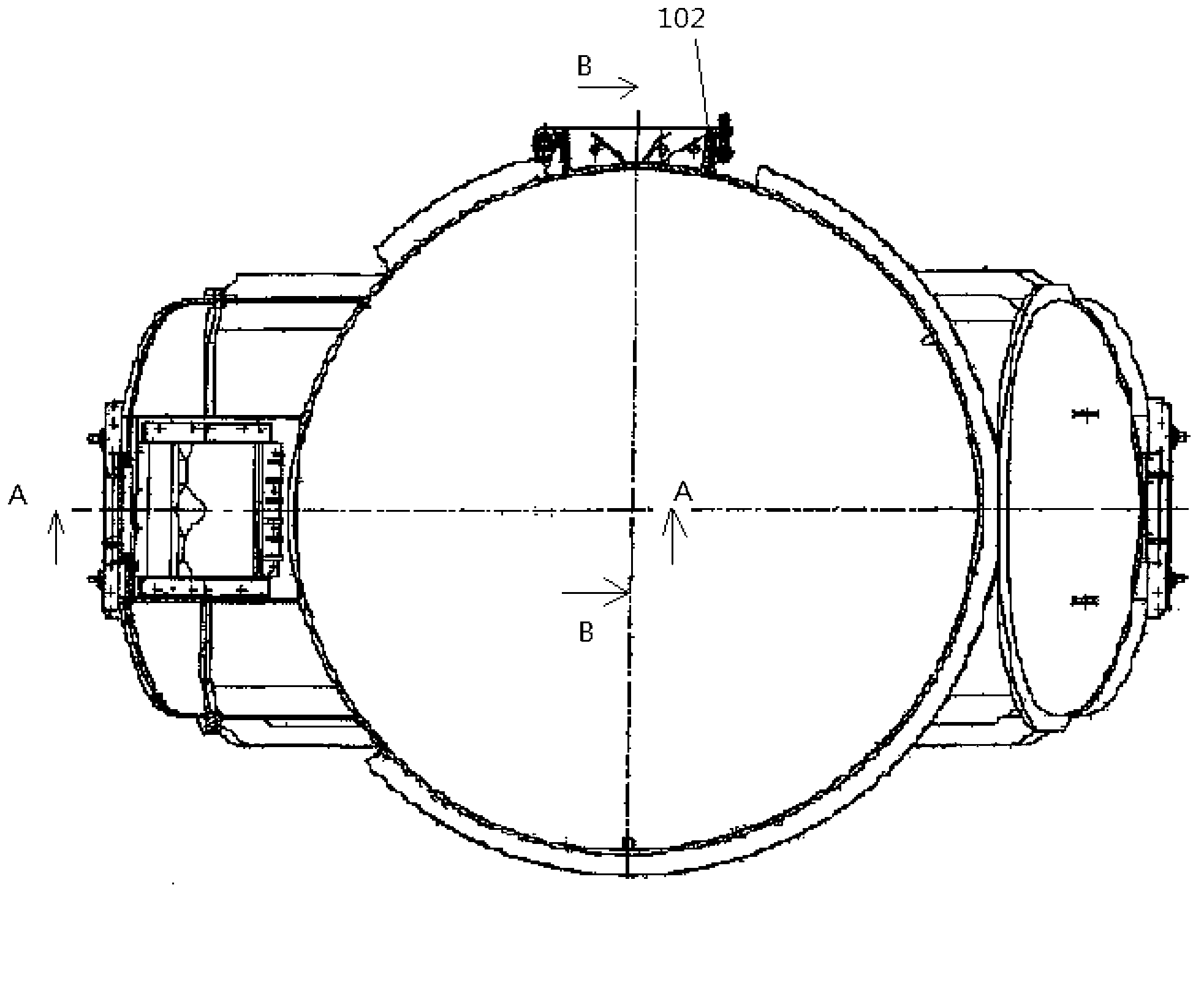

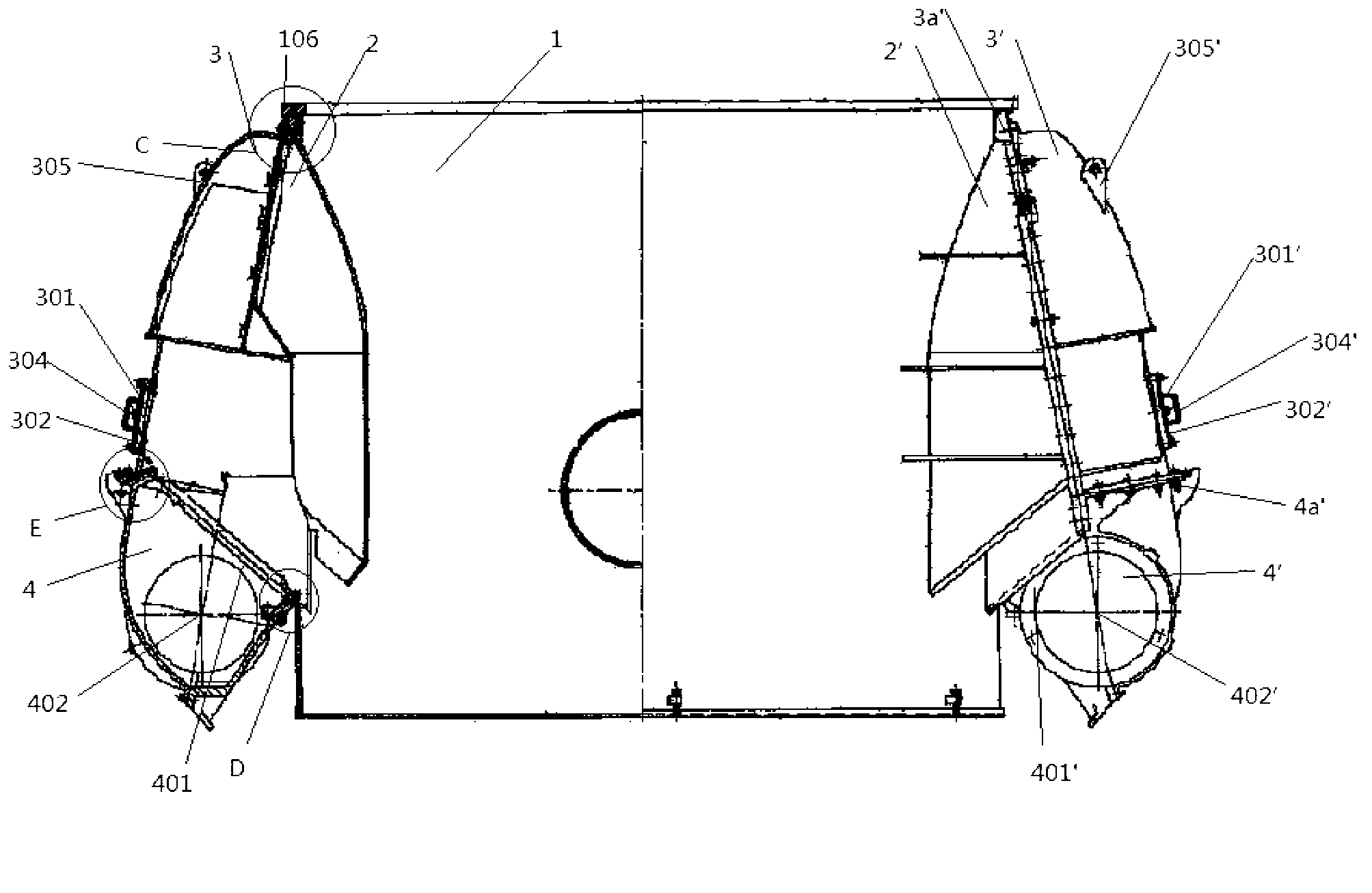

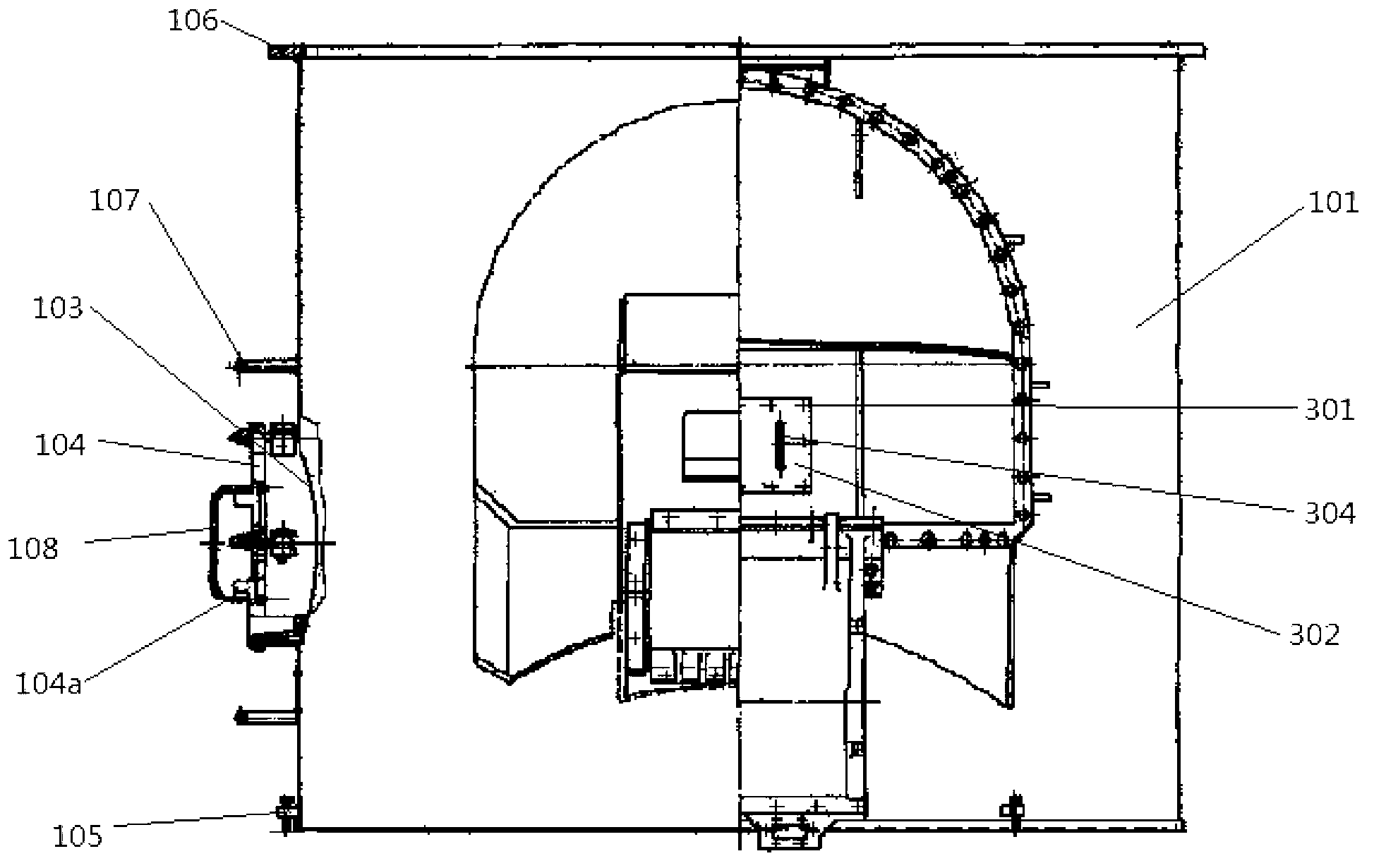

[0029] as attached Figure 1-11 As shown, a shell structure of a roller mill roller, which includes a shell body 1, the left and right sides of the shell body 1 are equipped with head installation ports 2, 2', and the head installation ports 2, 2' are equipped with grinding roller seals. The bottom of the head 3, 3', the grinding roller head 3, 3' is fixed with the pressure shaft installation part 4, 4', which is characterized in that the outer edge of the grinding roller head 3, 3' protrudes from the head fixing part 3a, 3a', threaded holes are opened on the head fixing parts 3a, 3a', and threaded holes are tapped at the corresponding positions of the outer protrusions of the head installation ports 2 and 2' on the left and right sides of the shell body 1. The roller head 3, 3' is locked in the threaded hole of the outer protrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com