Downhole Liquid Sand Multistage Separator

A technology of separators and grit holes, applied in the direction of boreholes/well components, production fluids, settling tanks, etc., can solve problems such as clogged liquid inlet holes and separators that cannot work normally, and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

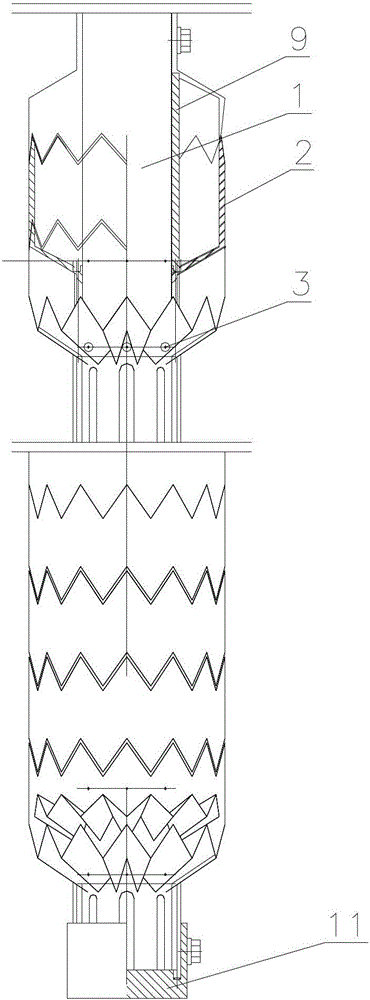

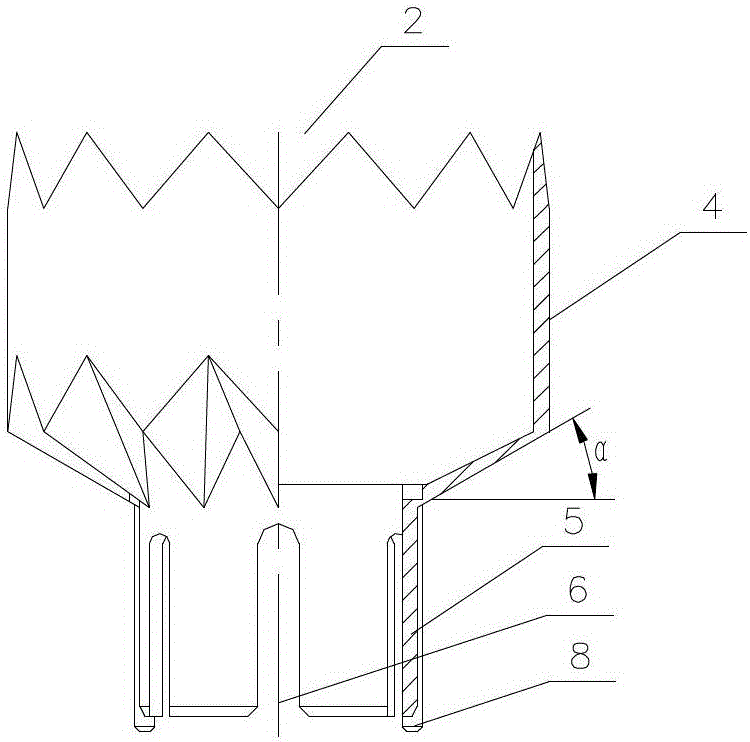

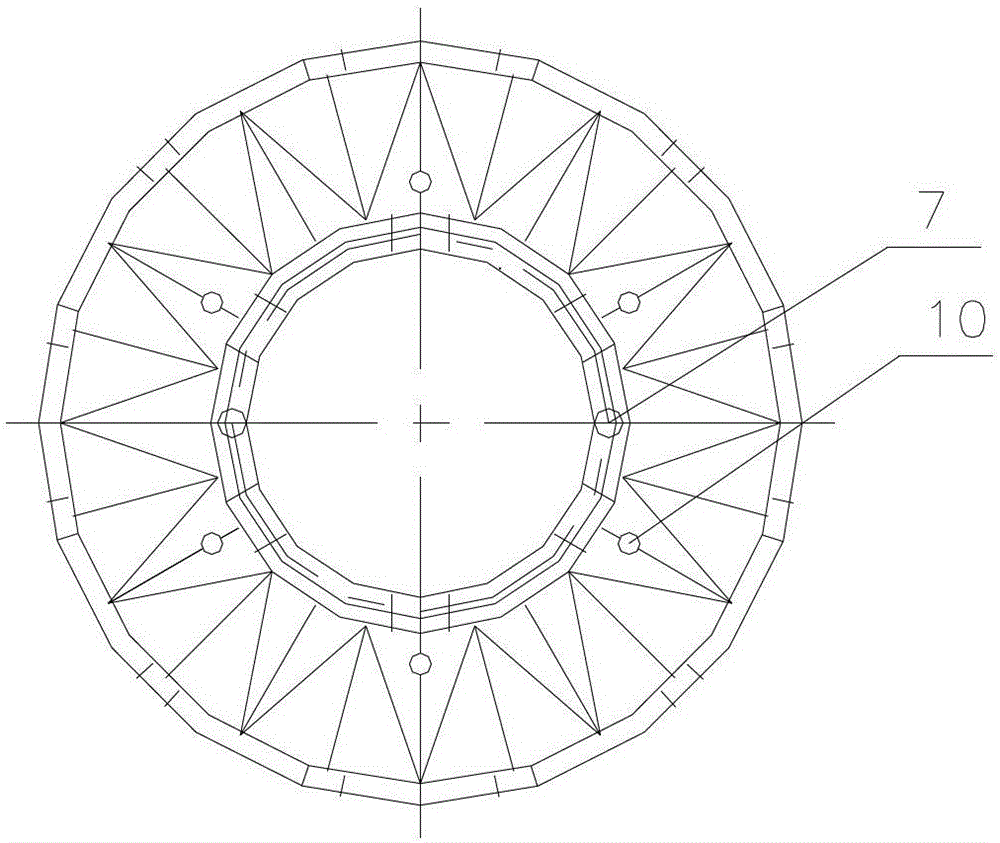

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] Depend on figure 1 combine figure 2 , 3 Shown: the downhole fluid-sand multi-stage separator of the present invention comprises a center pipe 1 and several settling cups 2 equidistantly sleeved on the center pipe 1, there are gaps between adjacent settling cups 2, and the settling cups 2 include The cup body 4 and the cup holder 5, wherein the bottom surface of the cup body 4 is polygonal, and the angle α between the outer convex edge of the polygonal surface and the horizontal line is 30°~60°, and the edge surfaces and ridge lines can make the oil droplets collide Merge and aggregate to form larger diameter oil droplets; the center pipe 1 corresponding to the annular space between the cup body 4 of the settling cup 2 and the center pipe 1 has a group of equal-diameter liquid inlet holes 3 .

[0016] The upper edge of the settling cup 2 below is a zigzag shape m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com