Water circulation pre-heating type corncob drier

A technology of corn ear and water circulation, applied in the direction of storing seeds by drying, etc., can solve the problems of low hot air temperature and unsatisfactory preheating effect, and achieve the effect of improving uniformity and drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

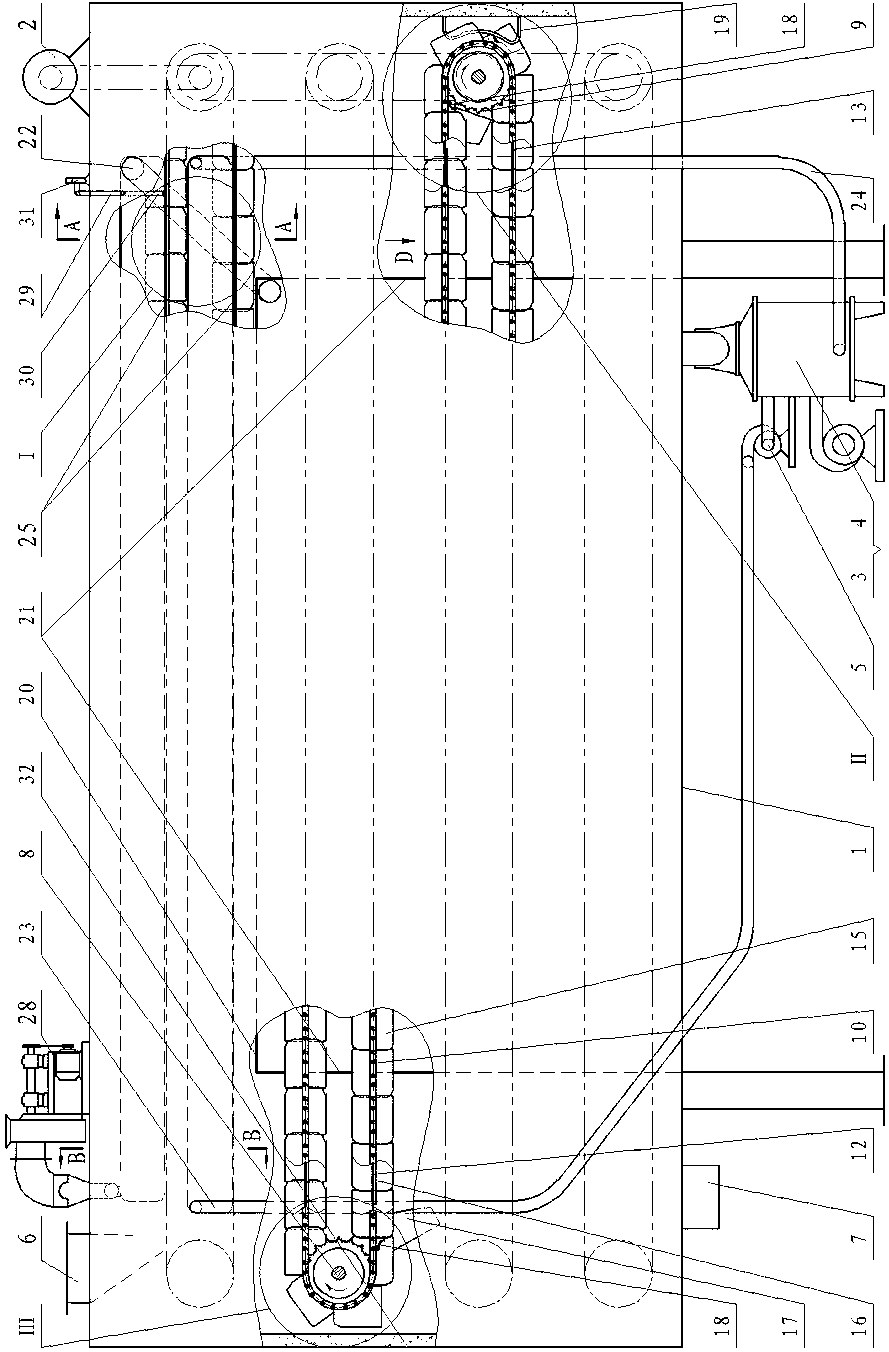

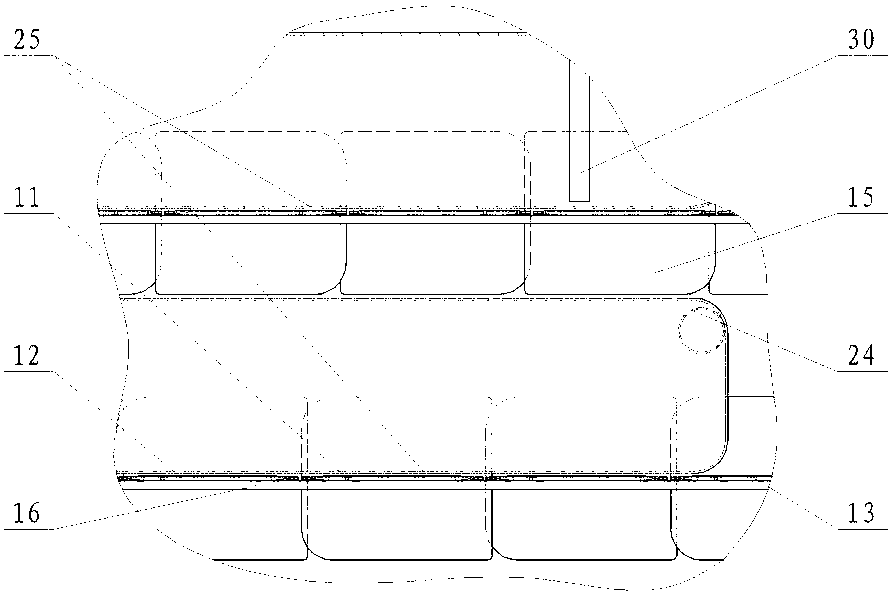

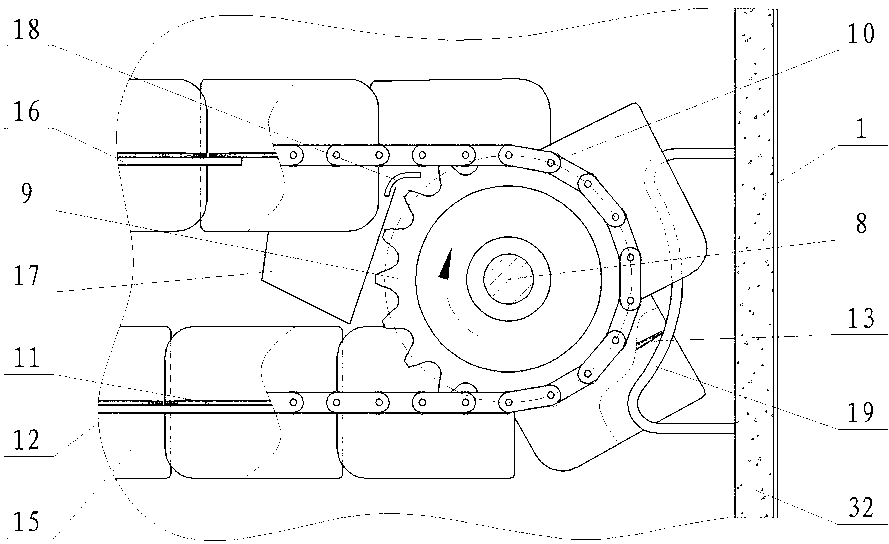

[0028] 1. Box body 2, transmission device 3, water and air heater 4, blower 5, circulating water pump 6, material inlet 7, material outlet 8, shaft 9, sprocket 10, chain 11, pin shaft 12, ventilation hole 13 , forming panel 14, hanging hole 15, baffle plate 16, guide rail 17, material guide groove 18, guide rod 19, limit rod 20, partition I 21, partition II 22, "C" shaped air duct 23, Water supply pipe 24, water return pipe 25, heat exchange box 26, "T" shaped air pipe 27, straight air pipe 28, induced draft fan 29, annular water pipe 30, straight water pipe 31, condensate water pump 32, insulation layer.

[0029] exist Figure 1~12In the shown embodiment: the top left end of the rectangular box body 1 is provided with a feed inlet 6, and the same end is provided with a discharge port 7 at the bottom of the box body 1, and the box body 1 is provided with 4 conveying devices along the length direction. The sequence numbers are Ⅰ, Ⅱ, Ⅲ, Ⅳ in turn. Both ends of the two shafts 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com