Hydraulic driving system of underwater acoustical generator

A driving system and sound generator technology, applied in the direction of the transducer used underwater, can solve the problems of increasing the length and complexity of the system pipeline, the single movement form of the hydraulic drive system, the size and weight of the sound generator, etc. Compact structure, low requirements on cleanliness and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the drawings and embodiments.

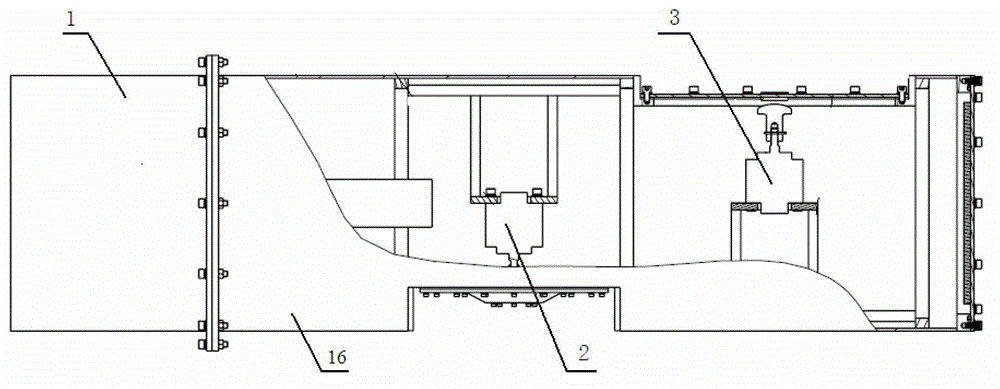

[0038] The new driving system of the sound generator for minesweeping provided by this embodiment controls two oil cylinders through a high-pressure oil source. The principle of the hydraulic driving system is as follows figure 1 As shown, high-pressure hydraulic oil is used as a power source, two independent oil cylinders are controlled as vibration output, and the sound radiating elements of two sound generators are respectively driven. In this embodiment, the sound radiating element of sound generator A is a rigid piston, and the sound radiating element of sound generator B is a diaphragm. Through the separate control of the two vibrating oil cylinders, two output types can be provided. The rigid piston is driven by the vibrating oil cylinder A to obtain the low-frequency radiation sound field, and the vibration oil cylinder B strikes the diaphragm to obtain the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com