Self-breathing direct methanol fuel cell

A methanol fuel cell and self-breathing technology, applied in fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of the anode being easily oxidized by air and reducing the stability of the battery, so as to prevent the anode from being oxidized , long discharge time and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

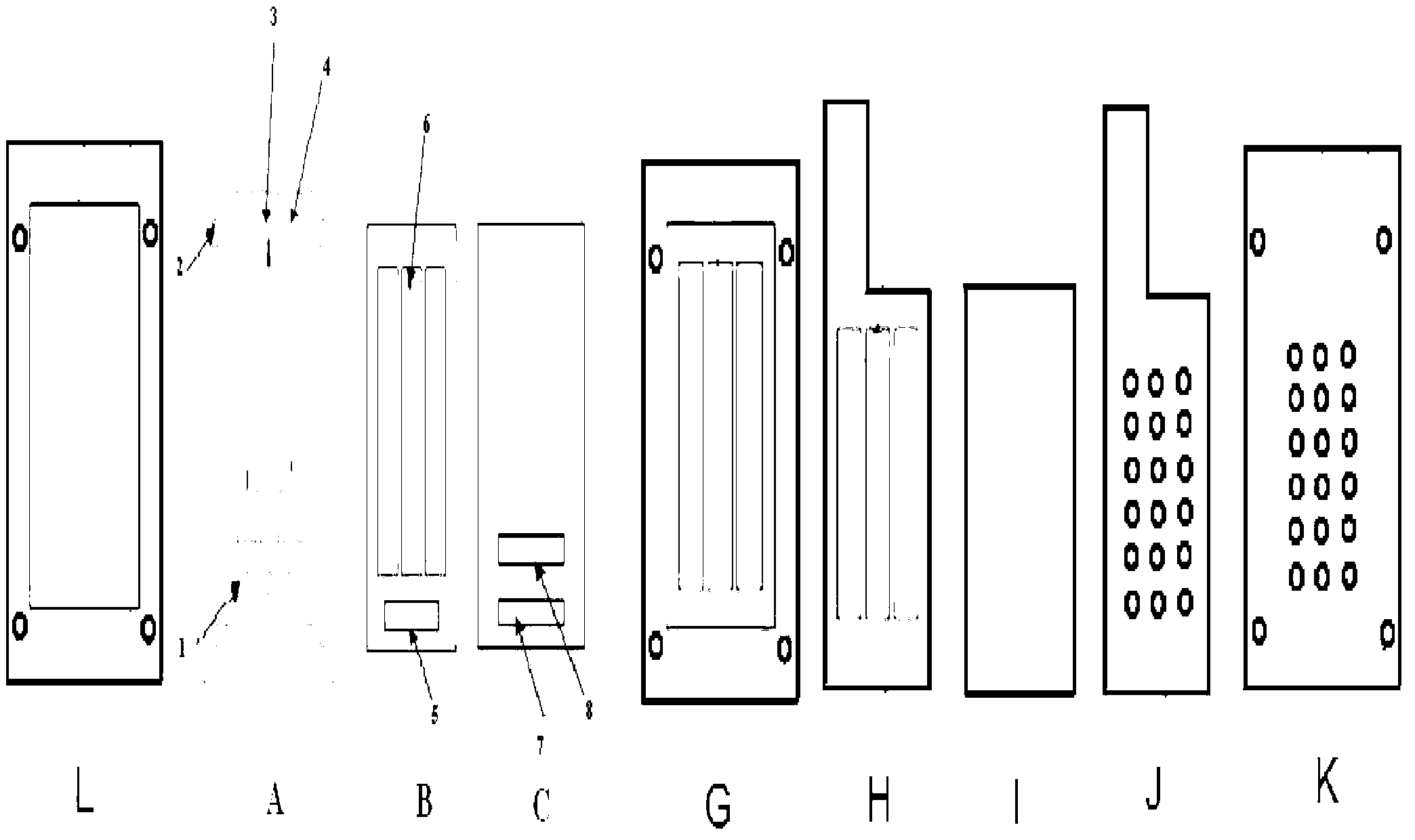

[0046] The structure of the self-breathing methanol direct fuel cell is as follows figure 1 shown.

[0047] The supporting board A is a glass fiber reinforced polyester board, the second air-permeable board B is graphite paper with a thickness of 0.8 mm, and the first air-permeable board C is a graphite board with a thickness of 0.8 mm.

[0048] The anode current collector H and the cathode current collector J are metal sheets with a thickness of 0.06 mm.

[0049] The effective work area of membrane electrode I is 2×2.5=5cm 2 .

[0050] The self-breathing direct methanol fuel cell of the present embodiment is subjected to a discharge test. When 10mL of 15M methanol solution is injected into the methanol storage tank, the self-breathing direct methanol fuel cell can operate between 0.3V and 0.4V at a current of 60 mA. Continuous discharge for 60 hours.

Embodiment 2

[0052] Ten self-breathing methanol direct fuel cells described in Example 1 were connected in series to form a stack, and 120mL of 15M methanol solution was used for the discharge test, and the discharge could be continued at 3V~4V for 50 hours at a current of 60mA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com