Preparation method for ZnO / CdS / Cu2ZnSnS4 pn junction nanorod arrays

A technology of nanorod arrays and seed layers, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of small effective battery area, restricting the process of commercial application, etc., and achieve a simple and easy preparation process , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

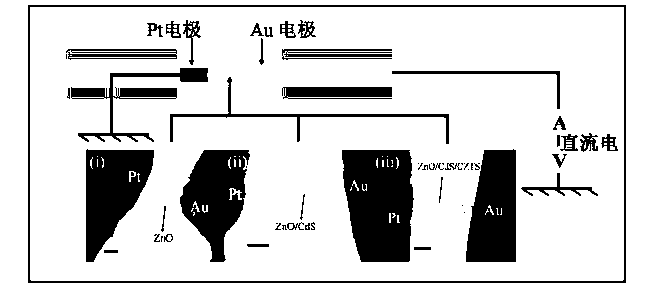

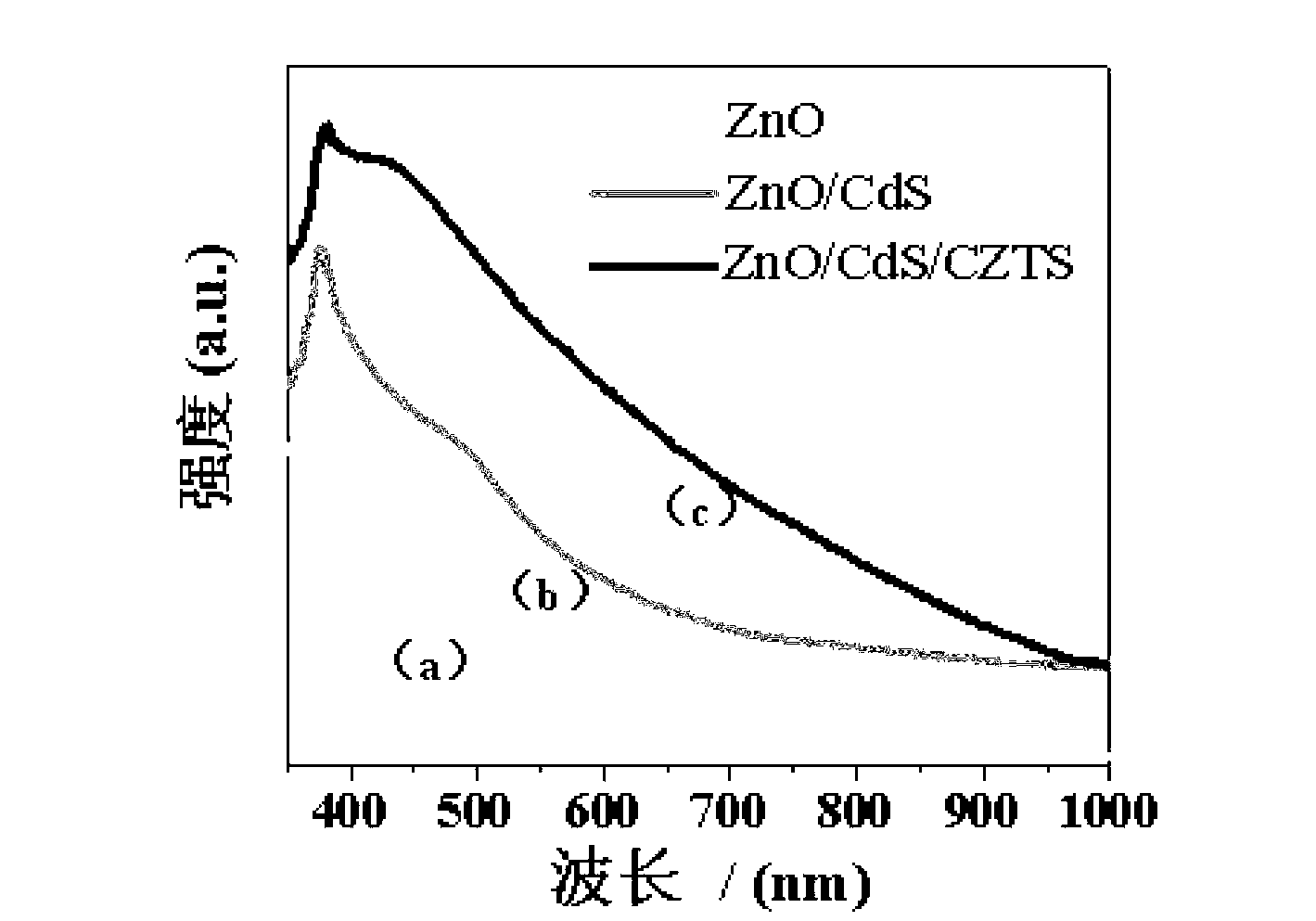

Method used

Image

Examples

Embodiment 1

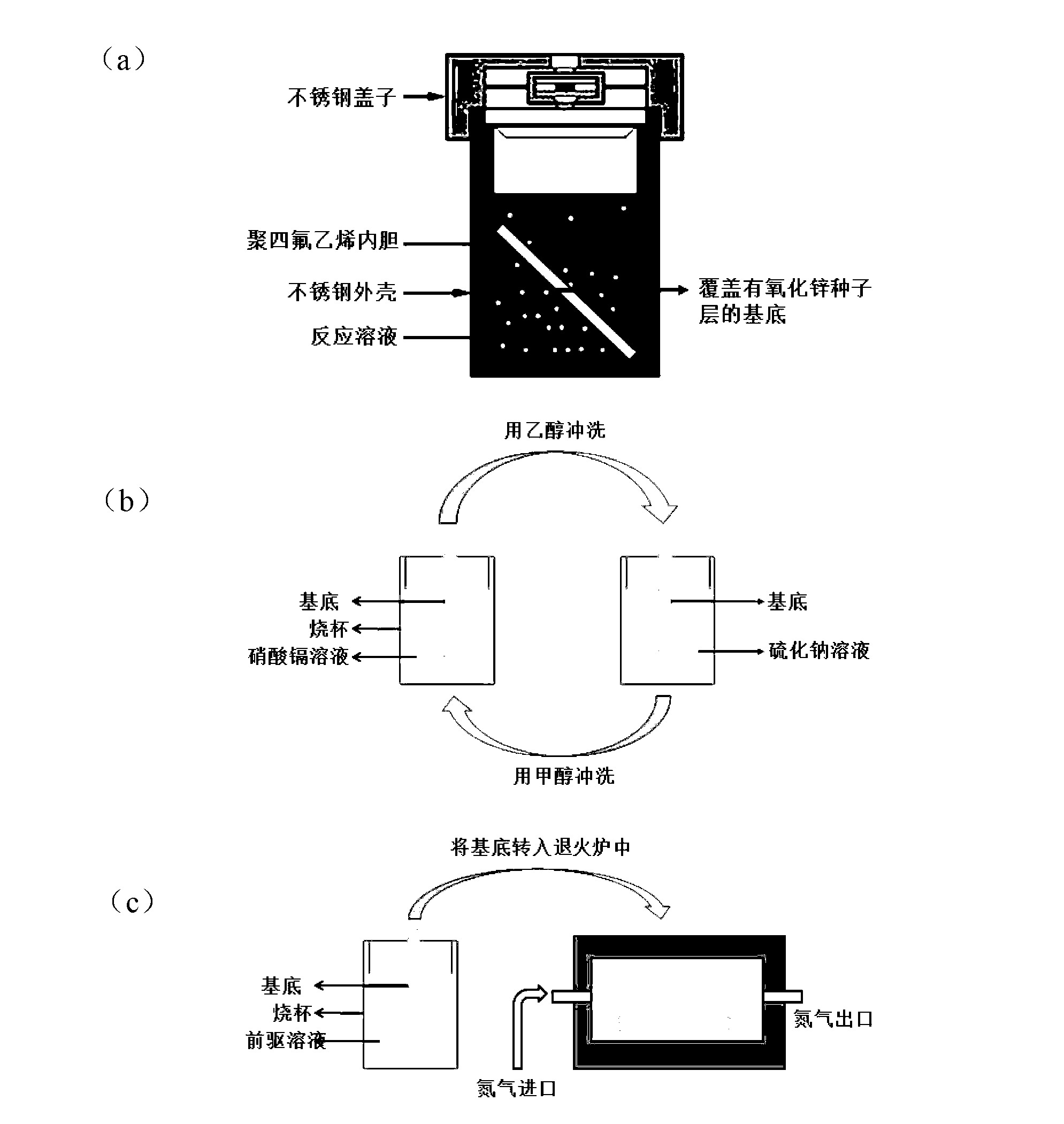

[0033] Before the hydrothermal reaction, the glass substrate was immersed in 0.005mol / L Zn(CH 3 COO) 2 2H 2 O in ethanol solution for 1 min, removed, rinsed with ethanol solution, then annealed in air at 420°C, and naturally cooled to room temperature. After the above operation was repeated 6 times, the ZnO seed layer was deposited on the glass substrate.

[0034] 0.025mol / L Zn(NO 3 ) 2 ·6H 2 The aqueous solution of O and the aqueous solution of 0.025mol / L HMTA (hexamethylenetetramine powder) are mixed at a volume ratio of 1:1, and the reaction solution and the glass substrate covered with the ZnO seed layer are simultaneously transferred into the reactor (such as figure 1 (a) shown), hydrothermal reaction at 80 °C for 12 hours to obtain ZnO nanorod arrays.

[0035] The ZnO nanorod arrays were annealed in air at 420 °C for 20 min, and then cooled naturally to room temperature. Through the continuous ion layer adsorption and reaction method, such as figure 1 As shown ...

Embodiment 2

[0044] Before the hydrothermal reaction, the glass substrate was immersed in 0.005mol / L Zn(CH 3 COO) 2 2H 2 O in ethanol solution for 1 min, removed, rinsed with ethanol solution, then annealed in air at 420°C, and naturally cooled to room temperature. After the above operation was repeated 6 times, the ZnO seed layer was deposited on the glass substrate.

[0045] 0.025mol / L Zn(NO 3 ) 2 ·6H 2 The aqueous solution of O and the aqueous solution of 0.025mol / L HMTA (hexamethylenetetramine powder) were mixed at a volume ratio of 1:1, and the reaction solution and the glass substrate covered with the ZnO seed layer were simultaneously transferred to the reactor, and the C under hydrothermal reaction for 12 hours to obtain ZnO nanorod arrays.

[0046]The ZnO nanorod arrays were annealed in air at 420 °C for 20 min, and then cooled naturally to room temperature. Through the continuous ion layer adsorption and reaction method, that is, the ZnO nanorods are first immersed in a 0....

Embodiment 3

[0050] Before the hydrothermal reaction, the glass substrate was immersed in 0.005mol / L Zn(CH 3 COO) 2 2H 2 O in ethanol solution for 1 min, removed, rinsed with ethanol solution, then annealed in air at 420°C, and naturally cooled to room temperature. After the above operation was repeated 6 times, the ZnO seed layer was deposited on the glass substrate.

[0051] 0.025mol / L Zn(NO 3 ) 2 ·6H 2 The aqueous solution of O and the aqueous solution of 0.025mol / L HMTA (hexamethylenetetramine powder) were mixed at a volume ratio of 1:1, and the reaction solution and the glass substrate covered with the ZnO seed layer were simultaneously transferred to the reactor, and the C under hydrothermal reaction for 12 hours to obtain ZnO nanorod arrays. The ZnO nanorod arrays were annealed in air at 420 °C for 20 min, and then cooled naturally to room temperature.

[0052] Through the continuous ion layer adsorption and reaction method, that is, the ZnO nanorods are first immersed in a 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com