Integrated long-focus measuring device based on Talbot-moire technology

A measurement device and a long focal length technology, which is applied in the direction of testing optical performance, etc., can solve the problems of complex optical system measurement environment, complex measurement process, inconvenient on-site measurement, etc., to achieve simple measurement process, improve measurement accuracy, and ensure consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments.

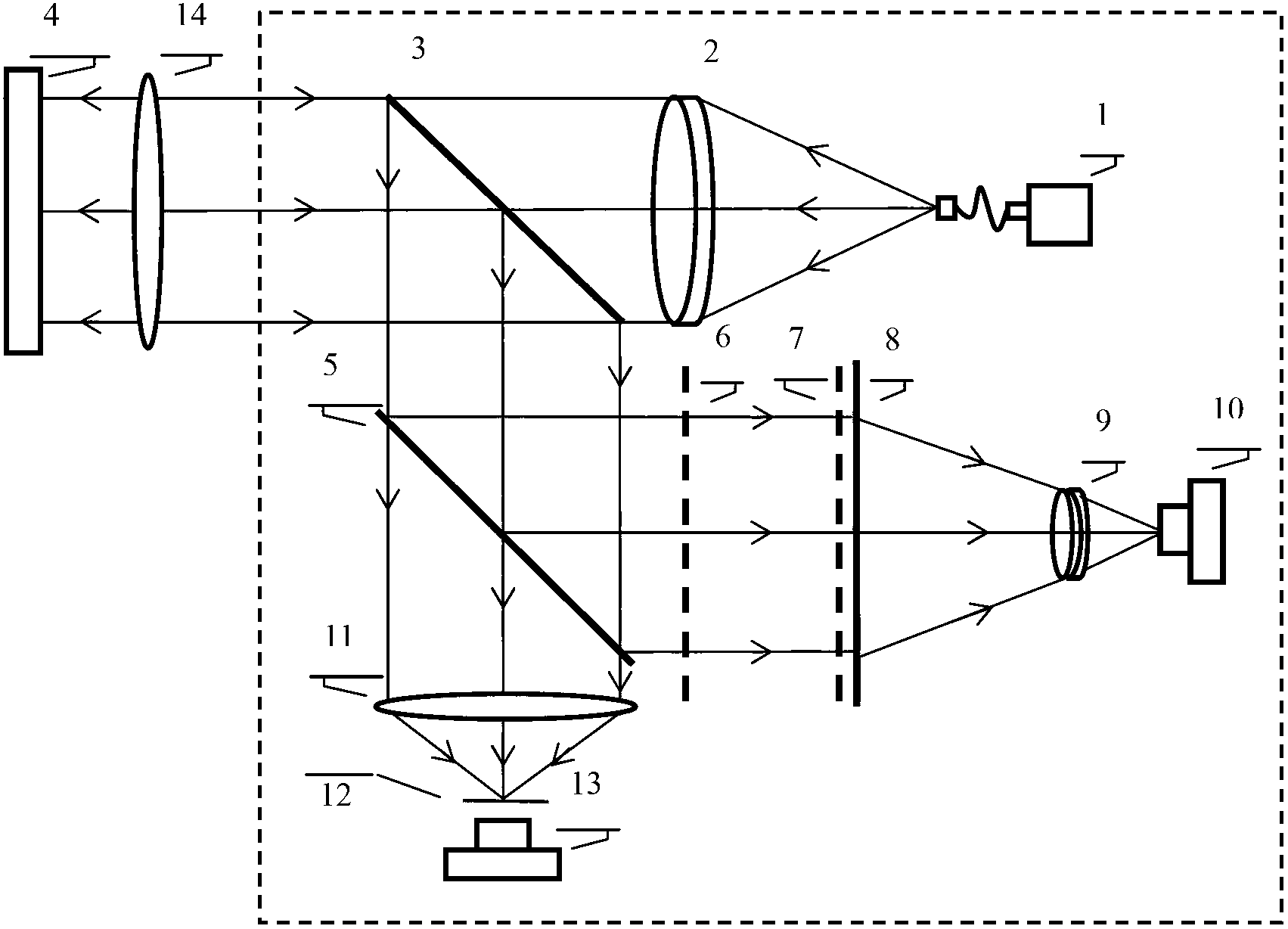

[0022] Combine figure 1 , The present invention is an integrated long focal length measuring device based on Taber-Moiré fringe technology, including a laser 1, an aspherical collimating objective lens 2, an antireflection lens 3, a plane mirror 4, a half mirror 5, The first grating 6, the second grating 7, the first scattering plate 8, the imaging lens 9, the first CCD 10, the condensing lens 11, the second scattering plate 12, the second CCD 13, and the long focal length lens 14 to be measured; the light emitted by the laser 1 After passing through the aspherical collimating objective lens 2, a collimated laser beam is formed, which is incident on the side of the anti-reflection lens 3 on which the anti-reflection lens 3 is coated with the anti-reflection coating and is completely transmitted. The transmitted light passes through the long focal length lens 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com