Closed type plane phase change hot accumulating tank heating system

A phase change heat storage and heating system technology, applied in heating systems, household heating, space heating and ventilation, etc. Complexity and other problems, to achieve the effect of convenient equipment installation and site requirements, stable temperature, and convenient transfer of installation sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

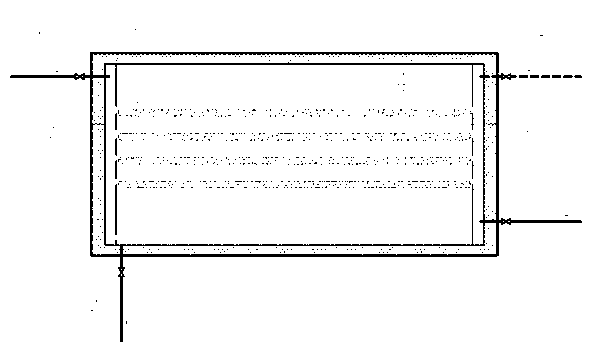

[0023] Example 1: Such as figure 1 As shown in the figure, the heating system of the closed flat plate phase-change heat storage tank is to install two detachable slotted plates 2 in the hot water storage tank 1, and the walls on both sides of the hot water storage tank 1 and the slotted plates 2 are enclosed. The diversion groove 3 is formed, the diversion groove 3 is connected with the inside of the heat storage tank, the phase change heat storage plate 4 is fixed on the card slot plate 2, the heat storage tank 1 is provided with an insulation layer 5, and the bottom of the heat storage tank 1 Install the heat exchange pipe 6 of the water tank, the heat exchange pipe 6 of the water tank is connected with the heating heat source 10, the water storage tank 1 is respectively connected with the water injection pipe 7, the hot water supply pipe 8, the water return pipe 9, and the drain pipe 11, and the water injection pipe 7 is used for replenishment The water volume of the hea...

Embodiment 2

[0027] Example 2 :Such as figure 2 As shown, on the basis of Embodiment 1, the hot water supply pipe 8 is connected to the hot water heat exchanger 12 for heat exchange and then sent back to the hot water storage tank 1 through the return pipe 9 to continue heating, and each water pipe is equipped with a valve to adjust the flow rate. The hot water heat exchanger 12 sends heat to the heating terminal 13 through the terminal water supply and return pipe. At this time, the hot water storage tank 1 and the heating terminal 13 exchange heat indirectly, and the connection mode is a closed terminal connection.

[0028] The invention can be used in building heating, equipment heating and other occasions that need to provide stable heat.

[0029] The heating system of the closed flat plate phase change heat storage tank of the present invention has the following operation process:

[0030] (1) see figure 1 , a closed-type flat-plate phase-change heat storage tank heating system w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com