Automobile urea box and forming method thereof

A molding method and urea tank technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of difficulty in controlling the uniformity of the wall thickness of the box body, the small volume of the Adblue storage box for vehicles, and the flying of raw material surplus Edge and other issues, to achieve the effect of saving raw materials, shortening the production cycle, and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

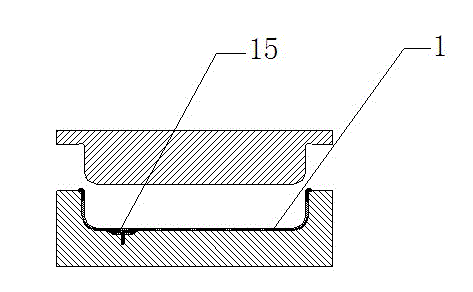

[0028] see figure 1 — Figure 6 , a method for forming an automotive urea tank, the method comprising the following steps, 1) producing an upper half shell 2 and a lower half shell 1 by an injection molding method, see figure 1 , 2 In the injection molding process, the anti-wave plate 13 and the assembly structure 16 of the surface parts of the box body can be injection molded together with the upper half shell 2, and the assembly screws 15 of the protection plate and the welding structure 21 of the sensor port can be injection molded together with the lower half shell 1 , the injection molding of the anti-wave plate 13 and the shell as a whole, firstly improves the degree of freedom in the design of the built-in components of the box, that is, the setting of the built-in components is no longer limited to the outer diameter of the box, and secondly reduces the follow-up welding work. 2) After the upper and lower half-shells are formed, assemble the built-in parts of the upp...

Embodiment 2

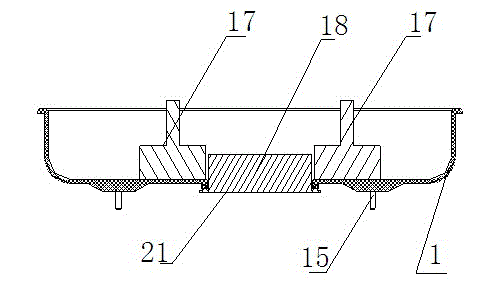

[0030] see image 3, as an improvement of the present invention, during the process of welding the built-in pump assembly 18 of the sensor port welding structure 21 to the lower half-shell 1, a baffle 17 is set on the inner wall of the lower half-shell 1, and the baffle is taken out after welding . Weld the pump assembly to the lower half shell, because the welding process needs to apply a large pressure to ensure the fusion between the two welded bodies, and the pressure is too high to easily deform the box, so the inner wall of the lower half shell Place the corresponding baffle plate 17. The baffle plate is made of metal material, thereby ensuring the stability of the shape of the shell under heavy pressure. The structural shape of the baffle plate matches the structure of the inner wall of the box. The baffles 17 are symmetrically arranged on both sides of the pump assembly 18. This method is not only simple and effective, but also saves a lot of raw materials. Traditi...

Embodiment 3

[0031] Example 3 : In step 1, the upper half shell 2 and the lower half shell 1 are produced by injection molding. In the injection molding process, the box body surface parts assembly structure 16 is injection molded together with the upper half shell 2, the anti-wave plate 13, the protective plate The assembly screw 15, the welded structure of the sensor port and the lower half shell 1 are injection molded together. The remaining steps and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com