Method for perforating and pre-burying polyvinyl chloride (PVC) wiring tubes in concrete hollow block filled walls

A technology of hollow block and installation method, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problems that the mortar strength cannot be guaranteed to fully meet the requirements, the stability of the wall structure is affected, and the labor cost is large. , to achieve the effect of simple and reliable construction operation, ensuring accuracy and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

[0030] The concrete hollow block filling wall pre-embedded PVC electric wire pipe threading installation method of the present invention comprises the following steps:

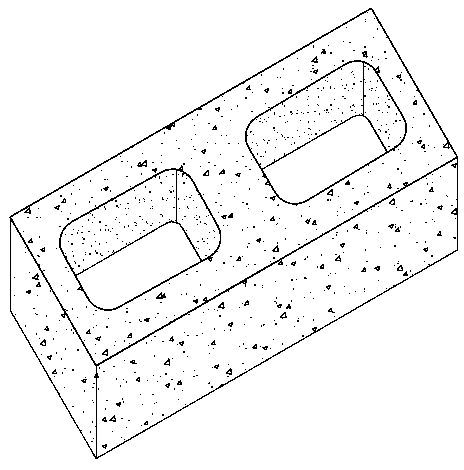

[0031] 1) First, according to the requirements of design drawings and hollow blocks (such as figure 1 Shown) the actual size, draw the wall layout diagram of the corresponding position, and locate the lead-out point of the pre-embedded PVC wire pipe in the cast-in-place slab according to the layout diagram;

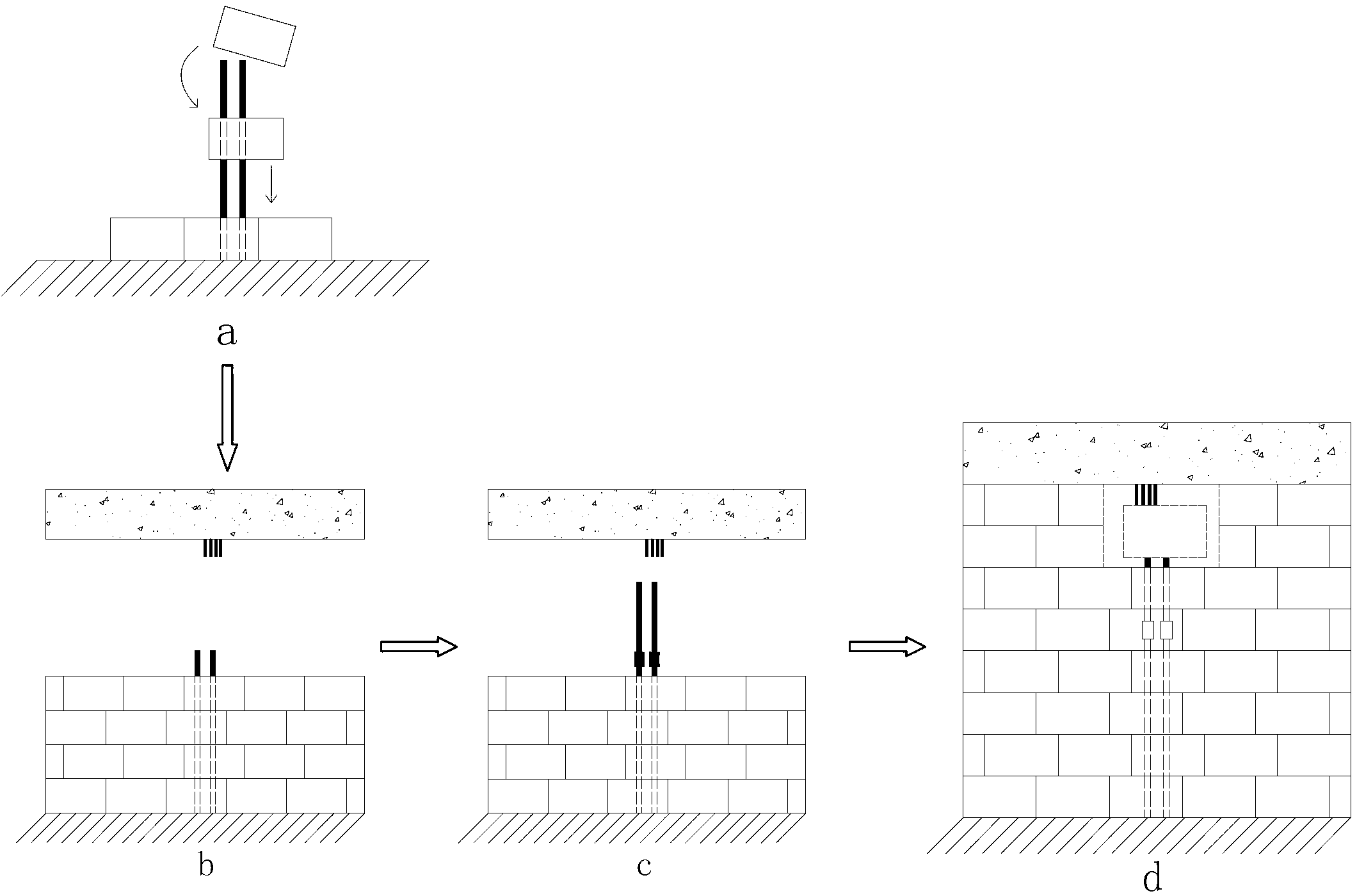

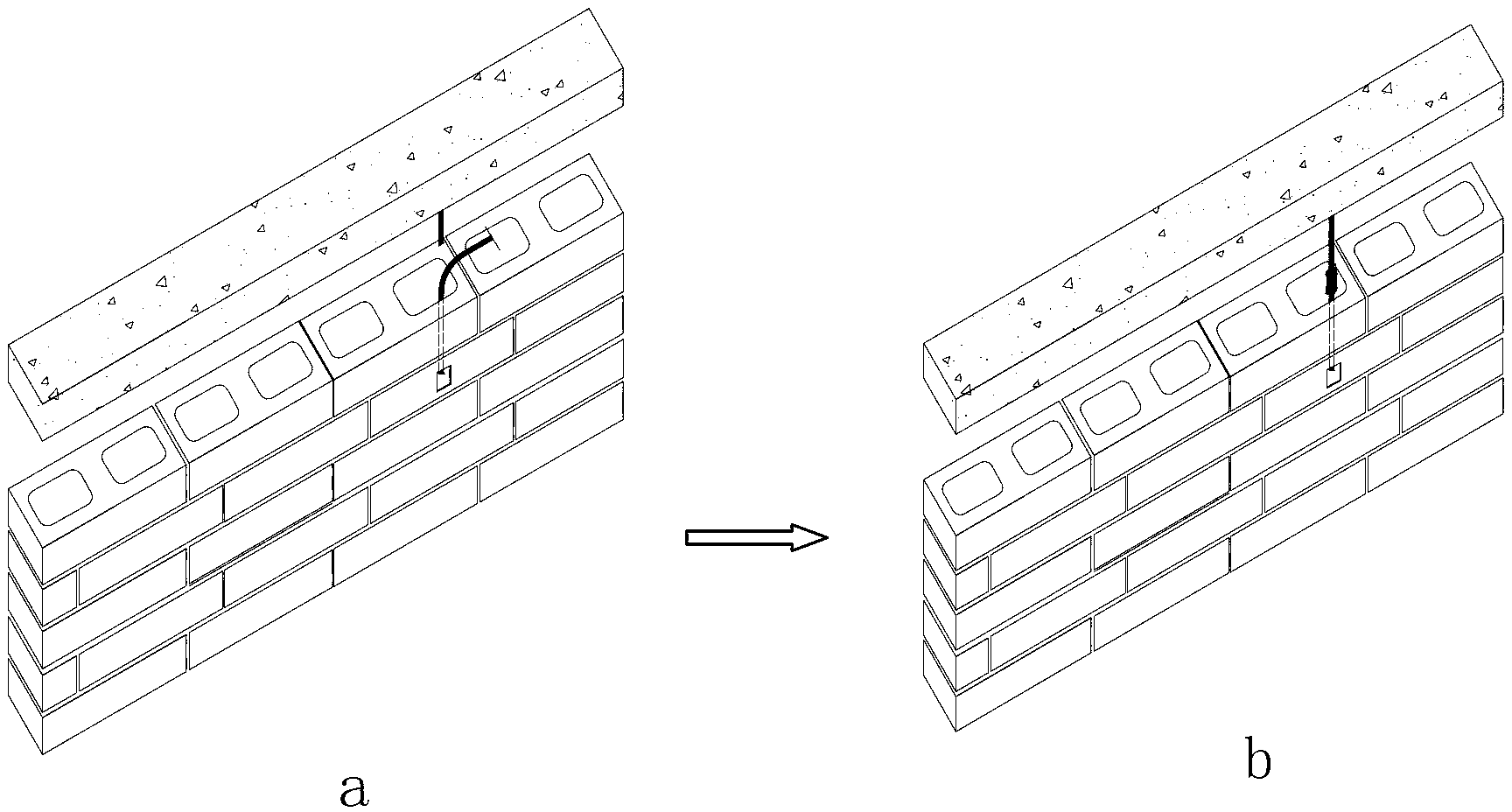

[0032] 2) The PVC wire pipes leading up from the bottom are connected to a certain height before the wall is built. When the wall is built, the hollow blocks are sequentially inserted into the wire pipes for masonry, so that the wire pipes are hidden in one time. In the cavity of the hollow block wall, and pre-embedded steel bars in sections to bind and fix the wire pipes (such as Figure 5 ), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com