Preparation method of menthol/SiO2 as tobacco flavor sustained-release material

A technology of menthol and slow-release materials, which is applied in the fields of tobacco, processed tobacco, essential oils/spices, etc., can solve the problems of loss, moisture and mildew, etc., and achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

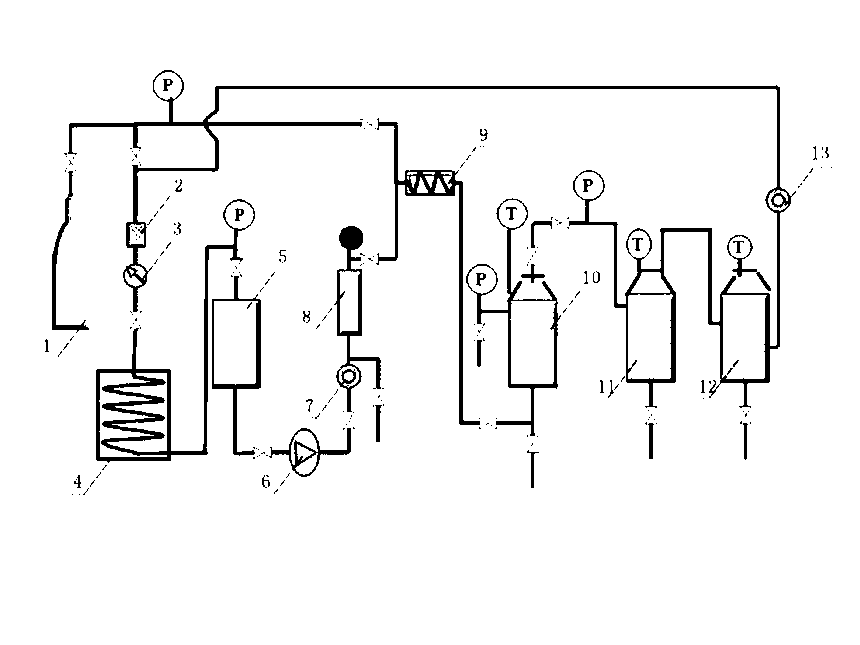

Image

Examples

Embodiment 1

[0027] 1. High Pore Volume Silica Particle Size Screening

[0028] Sieve the dried 1000 g high pore volume silicon dioxide product with a sample sieve, collect the product between 20-60 mesh, and set aside.

[0029] 2. Prepare materials

[0030] Weigh 200 grams of sieved (20-60 mesh) high-porosity silica material into a loading kettle, and weigh 400 grams of menthol into the dissolution kettle.

[0031] 3. Supercritical CO 2 preparation of

[0032] Turn on the CO 2 Cylinder 1 Valve, CO 2 The gas passes through the filter 2 to remove impurities, condenses into a liquid state through the refrigerator 4, enters the storage tank 5, and then pressurizes to 13 MPa through the high-pressure liquid pump 6, and then passes through the buffer tank 8 and then through the action of the heat exchanger 9, so that the CO 2 After the temperature is controlled at 35° C. to reach a supercritical state, it enters the dissolution kettle 10 .

[0033] 4. Supercritical CO of menth...

Embodiment 2

[0038] The operation steps are the same as in Example 1, except that the high-pressure liquid pump in step 3 is pressurized to 10 MPa, the cycle dissolution and load time in step 5 are changed to 10 hours, and the others remain unchanged.

[0039] Comparison of the effects of the two embodiments

[0040] 1. Determination of load

[0041] Adopt gas chromatograph to measure the menthol load capacity of gained product, embodiment 1 and embodiment 2 result are respectively: 1.67g menthol / gSiO 2 and 1.55 g menthol / gSiO 2 .

[0042] 2. Determination of Menthol Retention Rate

[0043] The product that the present invention obtains is that the nitrogen gas of 0.01Mpa is respectively purged 120min at the temperature of 25°C, 40°C, and 90°C with a pressure of 0.01Mpa, and measures its menthol retention rate. The test results of the two examples are basically the same, being respectively: 84.3% , 66.2%, 27.6%.

[0044] It can be drawn from the above two examples that: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com