Method and system for coalbed methane liquefaction

A technology for coalbed methane and liquefaction equipment, which is applied in the directions of liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve problems such as increasing the complexity of the system, and achieve the effects of improving the utilization rate, expanding the mining range and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

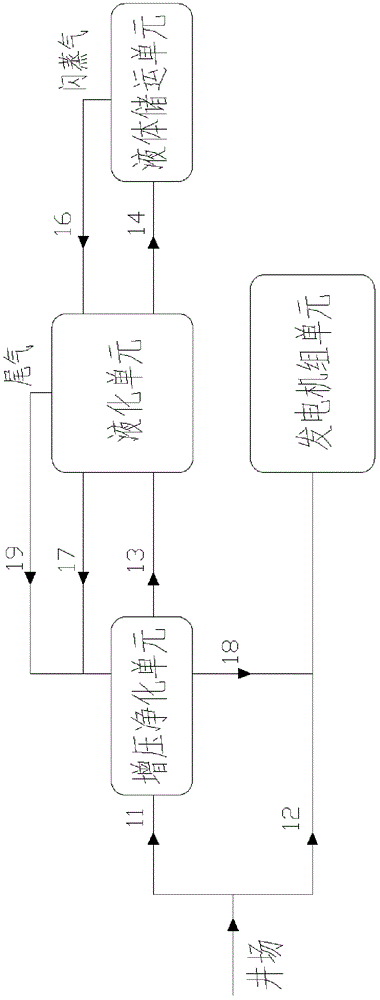

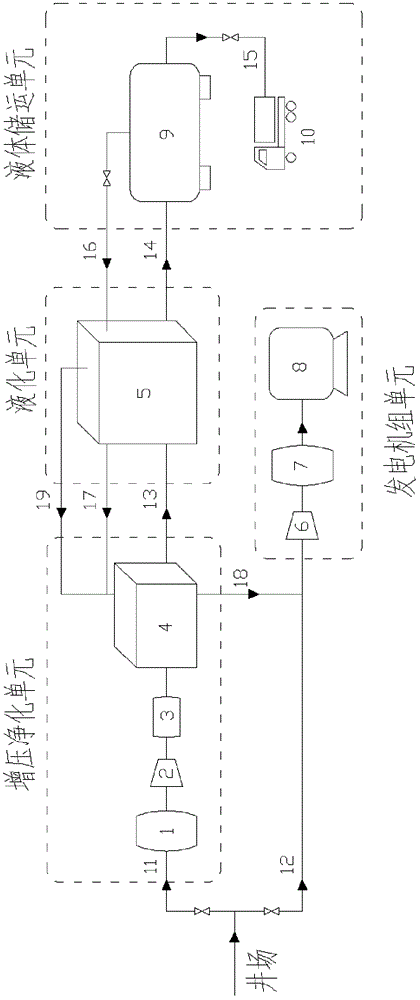

[0056] Such as figure 2 As shown, after the coalbed methane is extracted from the well site, the coalbed gas used for the liquefied part first enters the first surge tank 1 of the pressurization and purification unit through the pipeline 11, and then passes through the first booster 2 and the cooler in sequence 3 Carry out pressurization and cooling, and then remove water, acid gas and other impurities in the purification device 4 to become high-pressure normal temperature purified coalbed methane; after purification, normal temperature and high pressure (pressure can be between 1.0MPa and 1.2MPa) coalbed methane It enters the coalbed methane liquefaction device 5 through the pipeline 13, where it is cooled to become low-temperature liquefied coalbed methane. The liquefied low-temperature liquefied coalbed methane enters the liquefied coalbed methane storage tank 9 of the liquefied storage and transportation unit through the pipeline 14 for temporary storage, and waits for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com