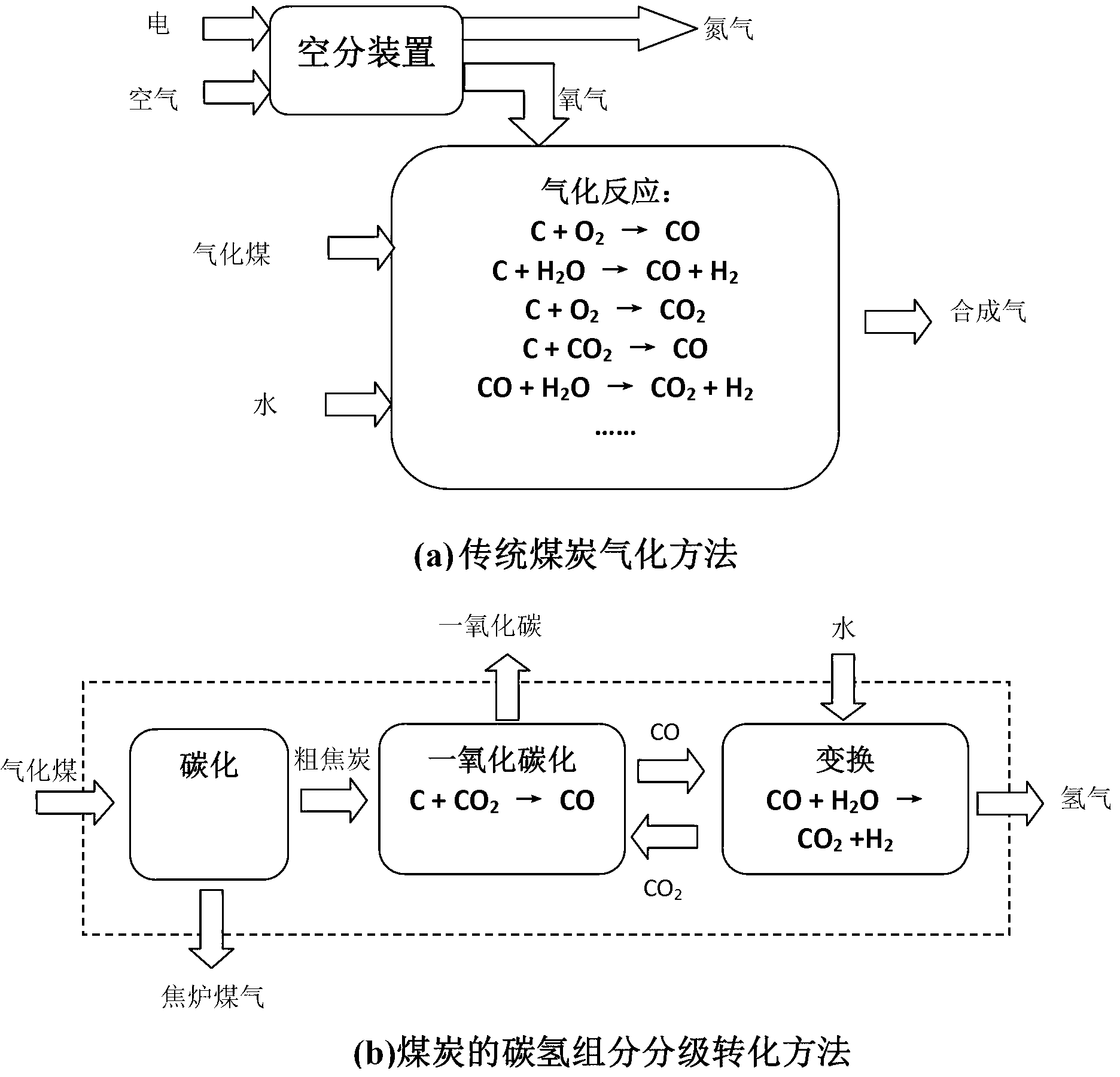

Gasification method for classification conversion of hydrocarbon components of coal

A technology of coal gasification and hydrocarbons, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of coal type limitation, high equipment investment cost, low gasification efficiency, etc., to reduce irreversibility and reduce equipment Effect of investment and gasification efficiency increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0040] Comparative example:

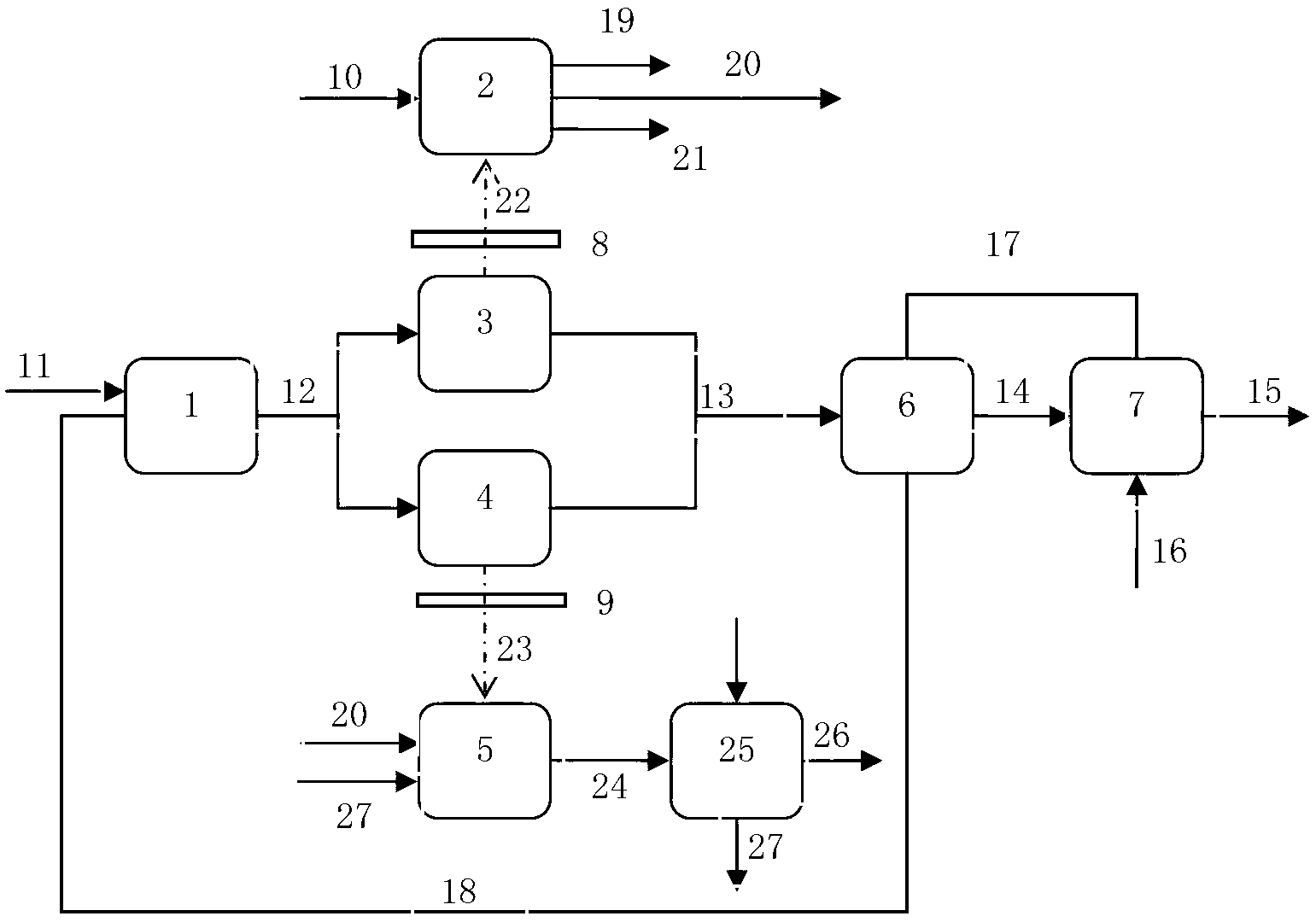

[0041] according to figure 2 As shown in the process flow of the hierarchical gasification of hydrocarbon components of coal supplied by external combustion, the operating conditions of the combustion unit 1 are: the pressure in the furnace is slightly positive, and the flue gas temperature is 1400-1700°C, according to the heat exchange cycle Moderate adjustment. In the new system, the exhaust gas temperature is 165℃. The carbonization unit refers to the actual test data of the coke oven (Table 3). The coking heat consumption per ton of coke produced is 3240MJ / t. Taking the temperature of the carbon monoxide production unit as 900°C, the carbon conversion rate is 0.95, and the heat exchange loss during the carbonization process and the carbon monoxide production unit process are both 5%.

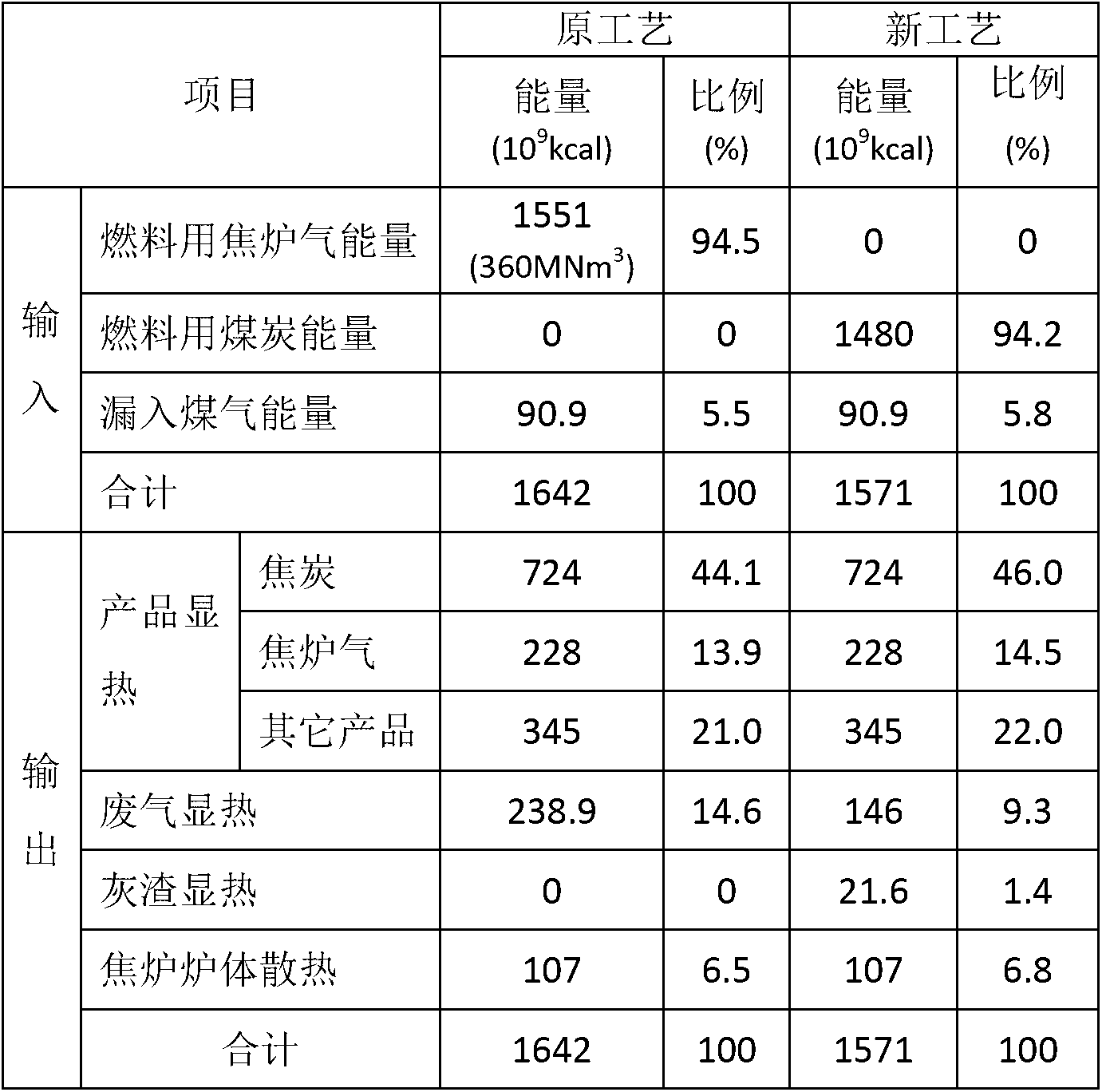

[0042] Table 1 shows the heat balance sheet of the coal carbonization unit. The coal carbonization unit in the new gasification can reduce fuel input by about 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com