Preparation method of high-polishing-rate rare-earth polishing powder

A technology of rare earth polishing powder and polishing rate, which is applied in the direction of polishing compositions containing abrasives, can solve the problems of high production costs, and achieve the effects of low cost, simple process and good polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

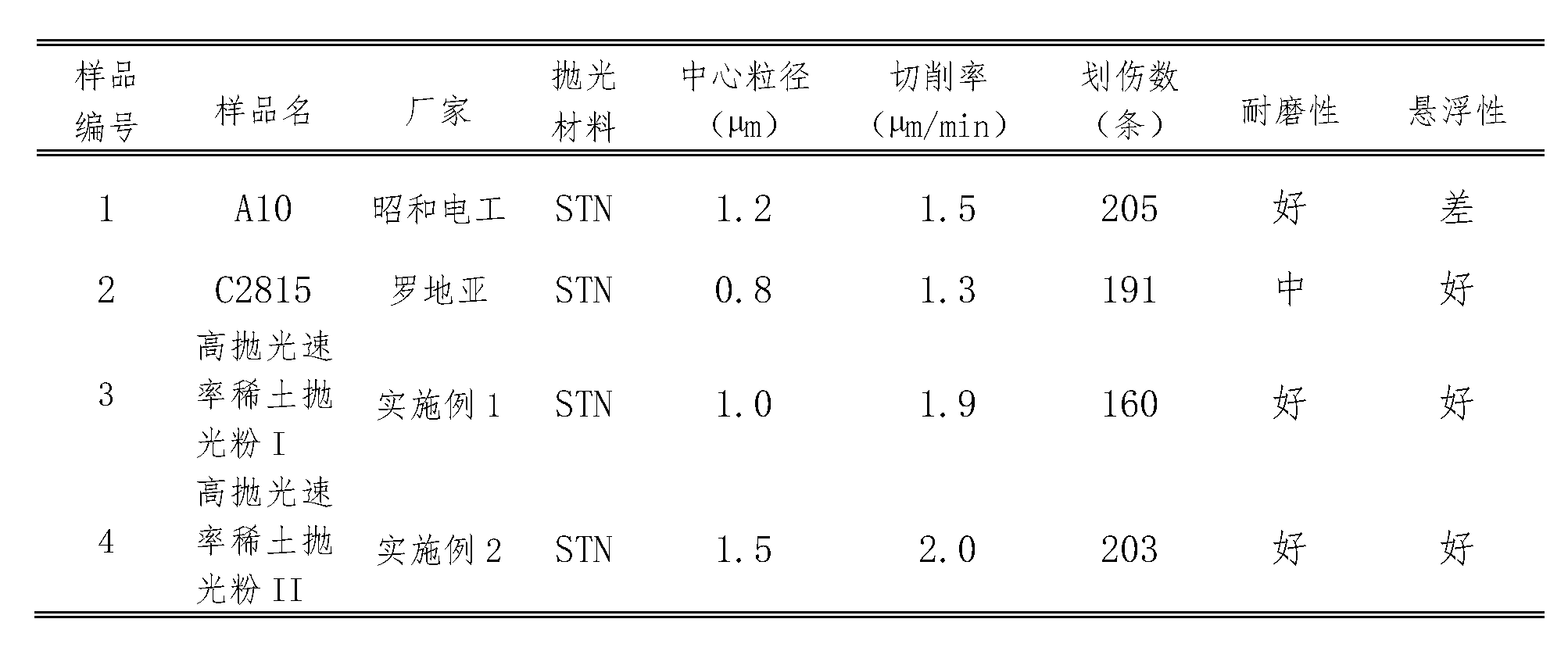

Embodiment 1

[0024] The preparation process of the present embodiment is as follows:

[0025] Add 4.5m to the reactor 3 Deionized water, and add 1000kg lanthanum cerium carbonate (in lanthanum cerium carbonate: the ratio of lanthanum cerium is 35:65 according to the oxide calculation, the central particle size is 18μm, and the rare earth oxide content is 45%) under stirring state, heated to 70 ℃, continue to stir for 1 hour, add 243.1kg of oxalic acid solution with a mass concentration of 10%, control the flow rate at 4L / min, and continue to react for 1 hour after the oxalic acid solution is added; ), rinse with deionized water until the conductivity of the filtrate is 2 / g of rare earth oxide microparticles to obtain 436kg of rare earth oxide microparticles; thereafter, the rare earth oxide microparticles obtained are packed into a mixer together with 2.80kg of sodium hexametaphosphate and 1.05kg of sodium chloride (this example uses 1m 3 Twin-screw conical mixer), mixing for 2 hours to ...

Embodiment 2

[0027] Add 4.5m to the reactor 3 Deionized water, and pour 1000kg lanthanum cerium praseodymium carbonate (in the lanthanum cerium praseodymium carbonate: the ratio of lanthanum cerium praseodymium according to oxide calculation is 29:69:2, central particle diameter 15 μ m, rare earth oxide content is 47 %), heated to 85°C, continued to stir for 4 hours, added 328.6kg of ammonium oxalate solution with a mass concentration of 20%, controlled the flow rate at 4L / min, and continued to react for 1 hour after adding the ammonium oxalate solution; (This example uses a PGZ1250N centrifuge), rinse with deionized water until the conductivity of the filtrate is 2 / g of rare earth oxide microparticles to obtain 441kg of rare earth oxide microparticles; thereafter, the obtained rare earth oxide microparticles are packed into a mixer together with 4.20kg of sodium polyacrylate and 0.25kg of sodium hydroxide (this example uses 1m 3 twin-screw conical mixer), and mix for 2 hours to obtain hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com