Composite modified asphalt of styrene butadiene styrene block polymer (SBS) and rubber powder and preparation method thereof

A technology of composite modified asphalt and rubber powder, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems that the effect of asphalt modification is not obvious, the effect of matrix asphalt modification is not very obvious, etc., and the construction process is reasonable and feasible , the effect of noise reduction is obvious, and the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

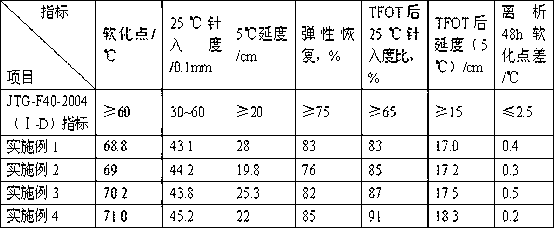

Examples

Embodiment 1

[0020] The present invention is to design a rubber powder / SBS composite modified asphalt, its components include stabilizer 3‰, activator 0.3‰, rubber powder 10%, SBS 2%, styrene-butadiene rubber filler oil 3%, the rest is matrix asphalt .

[0021] The rubber powder used in the present invention adopts tire rubber powder ground and pulverized at normal temperature, and uses bias tire powder or rubber powder with a higher content of natural rubber powder, and the rubber powder specification adopts 60 mesh. The stabilizer is a synthetic substance, the activator is sulfur powder, and the styrene-butadiene rubber filling oil is processed from furan formaldehyde.

[0022] Taking the above-mentioned rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0023] 1) Divide the base asphalt into two parts with equal mass. The first part is first preheated to 125±2°C, and 2% (the proportions refer to the percentage o...

Embodiment 2

[0027] The present invention is to design a rubber powder / SBS composite modified asphalt, its components include stabilizer 4‰, activator 0.3‰, rubber powder 10%, SBS 2%, styrene-butadiene rubber filler oil 3%, the rest is matrix asphalt .

[0028] The rubber powder used in the present invention adopts tire rubber powder ground and pulverized at normal temperature, and uses bias tire powder or rubber powder with a higher content of natural rubber powder, and the rubber powder specification adopts 60 mesh. The stabilizer is a synthetic substance, the activator is sulfur, and the styrene-butadiene rubber filler oil is processed from furan formaldehyde.

[0029] Taking the above-mentioned rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0030] 1) Divide the base asphalt into two parts with equal mass. The first part is first preheated to 125±2°C, and 2% (the proportions refer to the percentage of the to...

Embodiment 3

[0034] On the basis of implementation case 4, the optimized case design of the present invention is a rubber powder / SBS composite modified asphalt, and its components include stabilizer 4‰, activator 0.3‰, rubber powder 15%, SBS 2%, styrene-butadiene Rubber filling oil 3%, the rest is base asphalt.

[0035] The rubber powder used in the present invention adopts tire rubber powder ground and pulverized at normal temperature, and uses bias tire powder or rubber powder with a higher content of natural rubber powder, and the rubber powder specification adopts 60 mesh. The stabilizer is a synthetic substance, the activator is sulfur, and the styrene-butadiene rubber filler oil is processed from furan formaldehyde.

[0036] Taking the above-mentioned rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0037] 1) Divide the base asphalt into two parts with equal mass. The first part is first preheated to 125±2°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com