Tower-type adsorption reactor and system and method thereof for removing heavy metal ions in water

A reactor and tower type technology, which is applied in the field of rapid removal of heavy metal ions in water source water, can solve the problems of large volume and subsequent environmental problems, and achieve the effect of large adsorption capacity, low power consumption and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

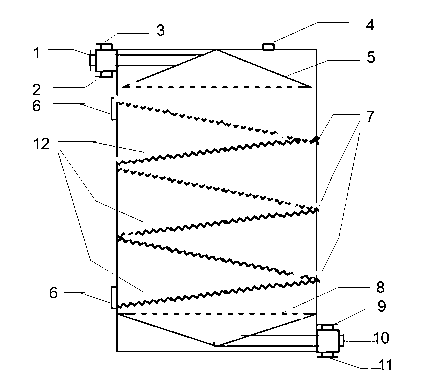

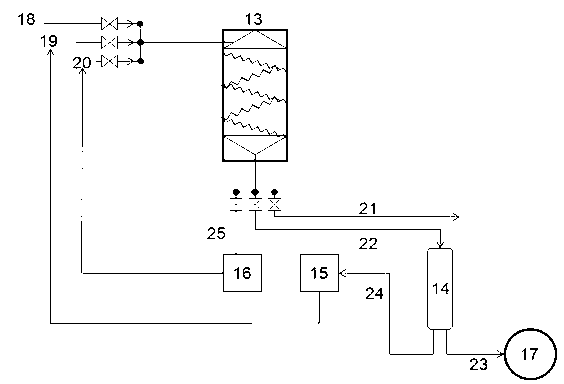

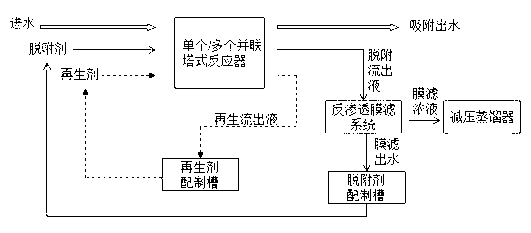

[0037] like figure 1 As shown, the tower adsorption reactor includes a tower body, a water distributor 5, a spiral porous pleated plate 7, a fiber adsorption material 12 and a water collector 8, and the water distributor 5 is located at the top of the tower, and the tower body has a spiral The porous pleated plate 7, the groove of the spiral porous pleated plate 7 is covered with fiber adsorption material 12, and the water collector 8 is at the bottom of the tower. The tower body is also provided with an observation window 6, and an air vent 4 is provided above the water distributor 5. A water inlet 1, a desorbent inlet 2 and a regeneration agent inlet 3 are respectively arranged on the top of the tower body, and are connected with the water distributor. The bottom of the tower is provided with a desorption effluent outlet 9, a water outlet 10 and a regeneration effluent outlet 11 respectively, and is connected with a water collector 8, and the tower body is circular. The sy...

Embodiment 2

[0049] The system used, influent water quality and operating conditions are the same as in Example 1, the tower body is square, but the influent flow rate is increased to 0.1 liters per second, and the effluent water quality after treatment is as follows Figure 8 . The results show that a single tower can continuously process 45,000 liters of water. Under the double-tower parallel mode, the two towers alternate adsorption-desorption regeneration, which can realize the uninterrupted operation of the system and effectively control the concentration of heavy metal ions in the adsorbed water to be lower than the concentration of heavy metal ions in the national drinking water hygiene standard. limit.

Embodiment 3

[0051] The system used, influent water quality and operating conditions are the same as in Example 1, but the thickness of the fiber material in the groove of the porous pleated plate is 0.04 meters, and the effluent water quality after treatment is as follows Figure 9 . The results show that a single tower can continuously process 43,000 liters of water. Under the double-tower parallel mode, the two towers alternate adsorption-desorption regeneration, which can realize the uninterrupted operation of the system and effectively control the concentration of heavy metal ions in the adsorbed water to be lower than the concentration of heavy metal ions in the national drinking water hygiene standard. limit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com