Vertical rotation pay-off stand

The technology of a vertical rotating and pay-off rack is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of inner wire rod extrusion, pulling down the pay-off rack, hidden dangers, etc. Achieving the effect of avoiding pressure line, facilitating production, convenient, efficient and smooth centralized pay-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

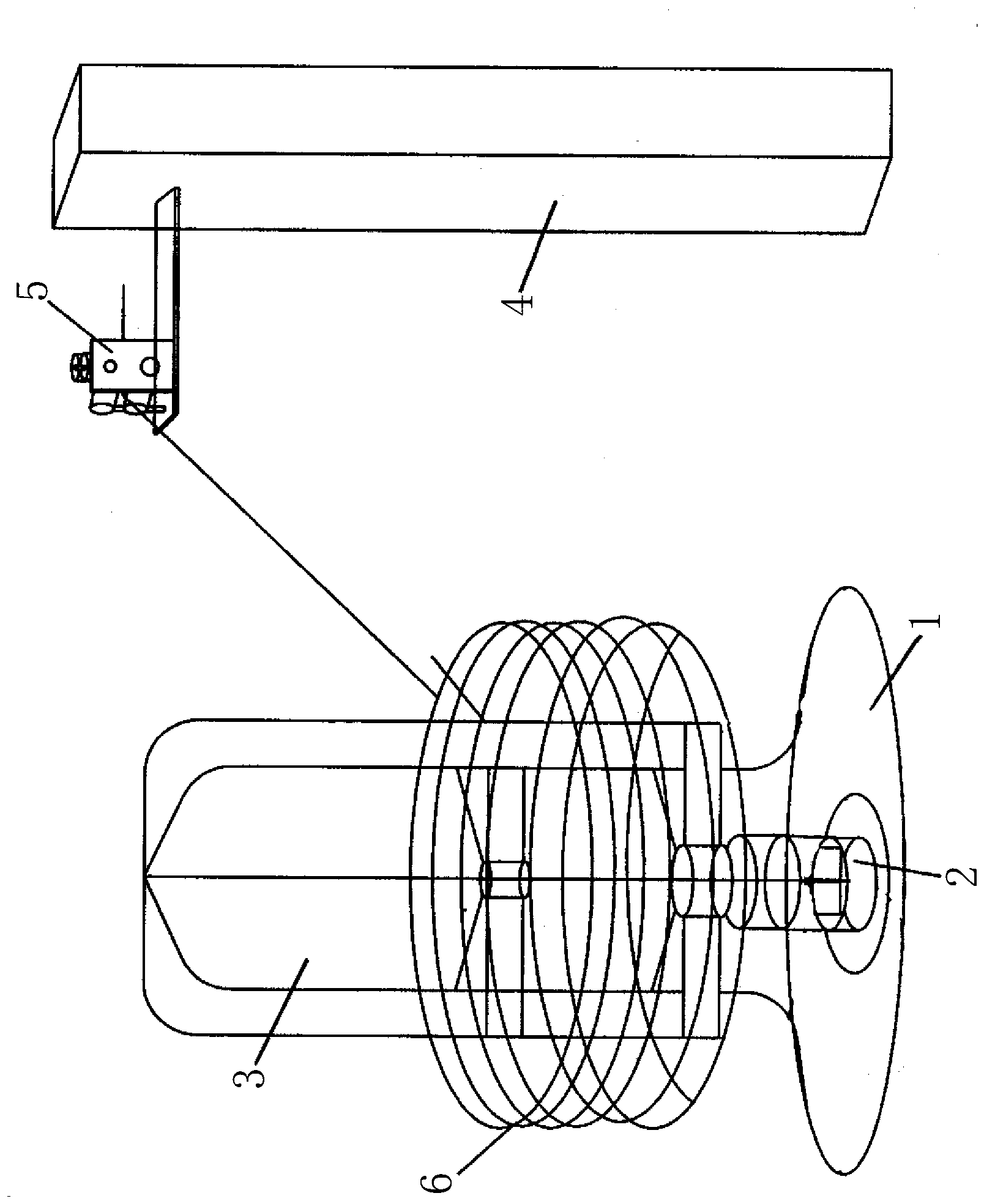

[0009] Such as figure 1 As shown, the present invention supports a pay-off frame 3 through a rotating shaft 2 in the middle of the chassis 1, a support 4 is arranged on one side of the pay-off frame 3, and a pull-out universal wheel 5 is provided at the upper end of the support 4. Through the above settings, the present invention is used for the pay-off of the bead wire rod 6, the bead wire wire rod 6 is connected to the production line via the drawing universal wheel 5, and the production line draws the bead wire wire rod 6 through the drawing universal wheel 5 , At the same time, the pay-off frame 3 realizes rotating and releasing the bead wire wire rod 6 under the action of the pulling force, which avoids the phenomenon of crimping and squeezing the wire, and improves the safety of production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com