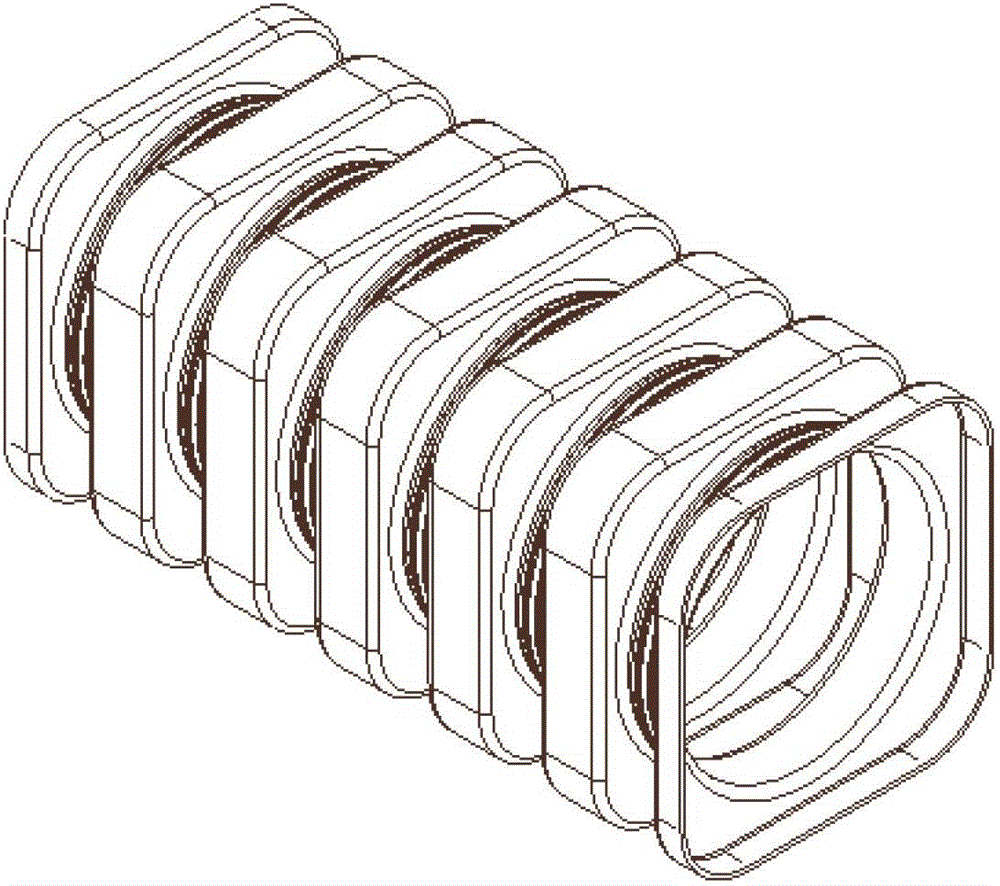

Forming mold of square single-wall corrugated pipe

A technology of single-wall bellows and forming molds, which is applied to household appliances, tubular objects, and other household appliances, etc. It can solve the problems of narrow vacuum channels, difficult processing, and poor product appearance quality, and achieves good vacuum effects and is easy to implement , to ensure the effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

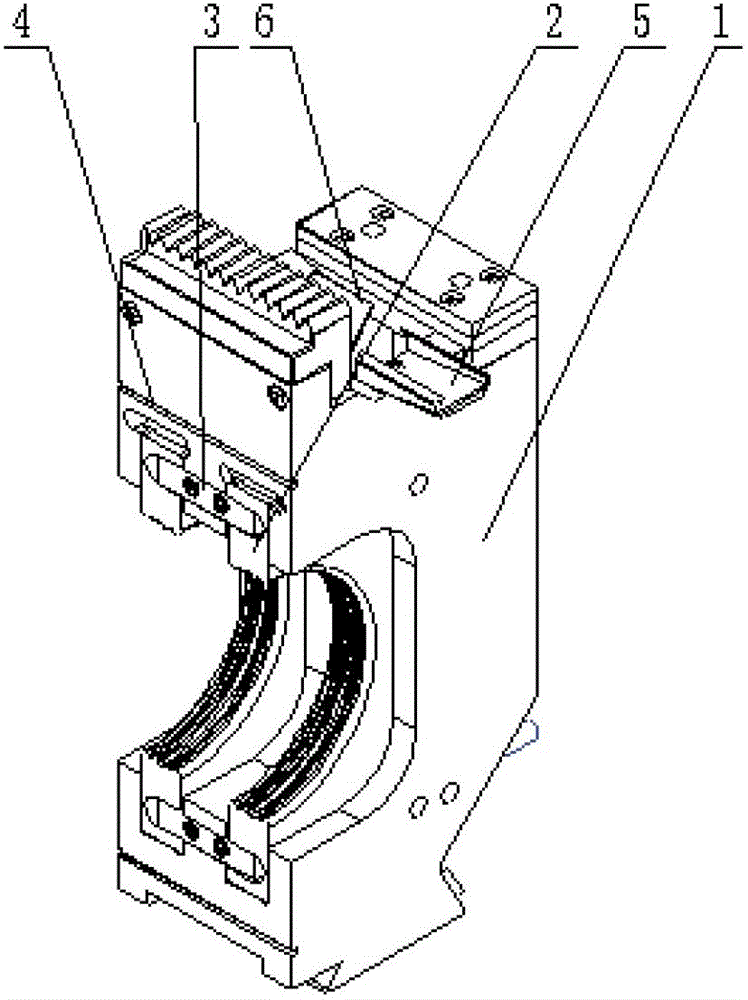

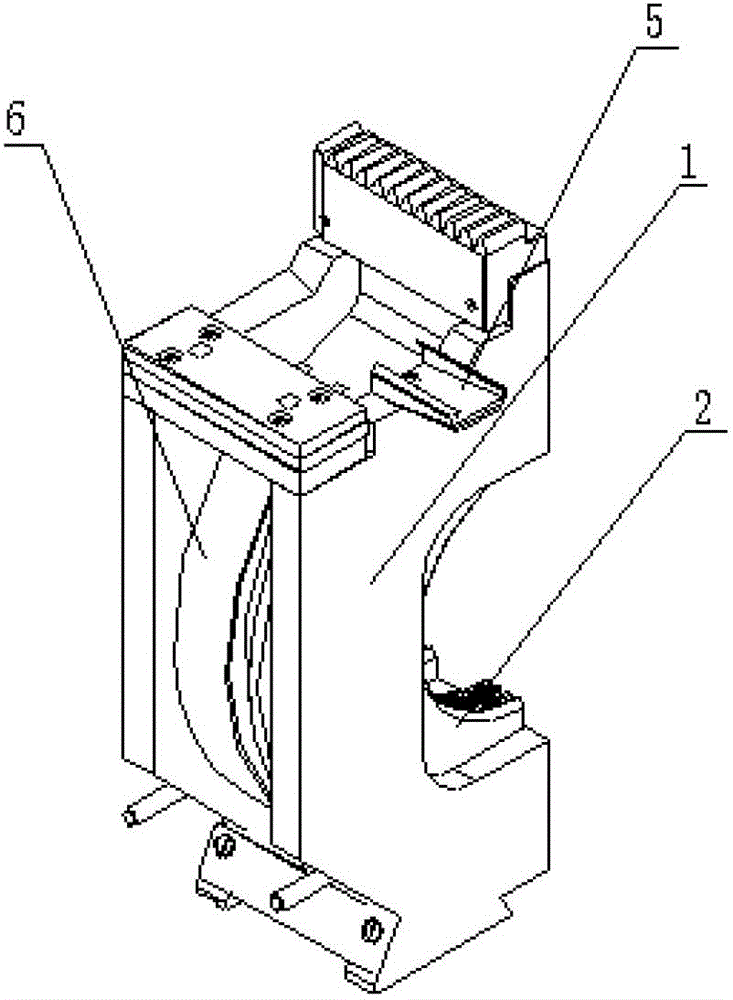

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] like figure 2 and image 3 Shown is the structural form of the square single-wall corrugated pipe forming die of the present invention. A split mold structure is adopted, a square hole 1a is milled out on the mold body 1, and a semi-circular groove 1b is turned out (see Figure 4 ) and then use the pressing block 3 to process the finished ring 2 (see Figure 5 ) is press-fitted in the semi-circular groove 1b of the mold body 1 to form the shape of a square single-wall bellows. Compared with the current monolithic structure, this split structure has simpler processing technology and shorter production period, and is suitable for mass production. A vacuum channel is processed on the mold body 1, and a vacuum groove is opened on the insert ring 2 to form a vacuum system. The vacuum system of this mold is easy to implement, the vacuum channel has a large space, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com