Preparation method of immobilized ionic liquid used for ester exchange reaction

A technology of transesterification reaction and ionic liquid, which is applied in the preparation of organic carbonate, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficult catalyst recovery and high cost, achieve good immobilization effect, reduce preparation cost, and improve catalytic activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

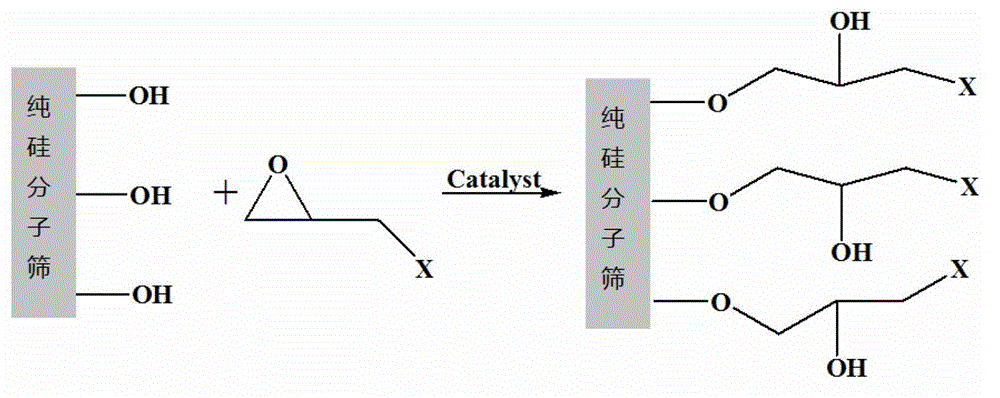

[0022] In the round bottom flask, add toluene, pure silicon molecular sieve MCM-41, epichlorohydrin and zinc chloride successively, wherein the mass ratio of pure silicon molecular sieve MCM-41 to toluene is 1:20, pure silicon molecular sieve MCM-41 and ring The mass ratio of oxychloropropane is 10:1, and the amount of zinc chloride is 2% of the mass of pure silicon molecular sieve MCM-41. The reaction was carried out under magnetic stirring at 80° C. for 6 hours to obtain a pure silicon molecular sieve whose surface hydroxyl groups were etherified.

[0023] Put the solid obtained in the above process into a round-bottomed flask, wash and dry it, then put it into a dry round-bottomed flask, and then add toluene and 1-methylimidazole in sequence, wherein the mass ratio of toluene to solid is 10:1, 1 - The mass ratio of methylimidazole to solid is 1:1, and heated to 80°C for 6 hours with magnetic stirring to obtain an immobilized ionic liquid catalyst supported by pure silicon m...

Embodiment 2

[0025] In the round bottom flask, add toluene, pure silicon molecular sieve MCM-48, epibromohydrin and ferric chloride successively, wherein the mass ratio of pure silicon molecular sieve MCM-48 to toluene is 1:50, pure silicon molecular sieve MCM-48 and ring The mass ratio of oxybromopropane is 5:1, and the amount of ferric chloride is 2% of the mass of pure silicon molecular sieve MCM-48. The reaction was carried out under magnetic stirring at 80° C. for 6 hours to obtain a pure silicon molecular sieve whose surface hydroxyl groups were etherified.

[0026] Put the solid obtained in the above process into a round bottom flask, wash and dry it, then put it into a dry round bottom flask, then add toluene and 1-ethylimidazole in sequence, wherein the mass ratio of toluene to solid is 10:1, 1 -The mass ratio of ethylimidazole to solid is 2:1, and heated to 80°C for 6 hours with magnetic stirring to obtain an immobilized ionic liquid catalyst supported by pure silicon molecular s...

Embodiment 3

[0028] Add toluene, pure silicon molecular sieve SBA-15, epibromohydrin and ferric chloride in turn in the round bottom flask, wherein the mass ratio of pure silicon molecular sieve SBA-15 to toluene is 1:30, pure silicon molecular sieve SBA-15 and ring The mass ratio of oxybromopropane is 6:1, and the amount of ferric chloride is 2% of the mass of pure silicon molecular sieve SBA-15. The reaction was carried out under magnetic stirring at 80° C. for 6 hours to obtain a pure silicon molecular sieve whose surface hydroxyl groups were etherified.

[0029] Put the solid obtained in the above process into a round-bottomed flask, wash and dry it, then put it into a dry round-bottomed flask, then add toluene and 1-propylimidazole in sequence, wherein the mass ratio of toluene to solid is 10:1, 1 - The mass ratio of propylimidazole to solid is 1:1, and heated to 80°C for 6 hours with magnetic stirring to obtain an immobilized ionic liquid catalyst supported by pure silicon molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com