Preparation method of low-pressure high-flux nanofiltration membrane

A technology of nanofiltration membrane and high low pressure, applied in the field of preparation of low pressure and high flux nanofiltration membrane, can solve problems such as complex process, and achieve the effects of high separation efficiency, large water flux and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

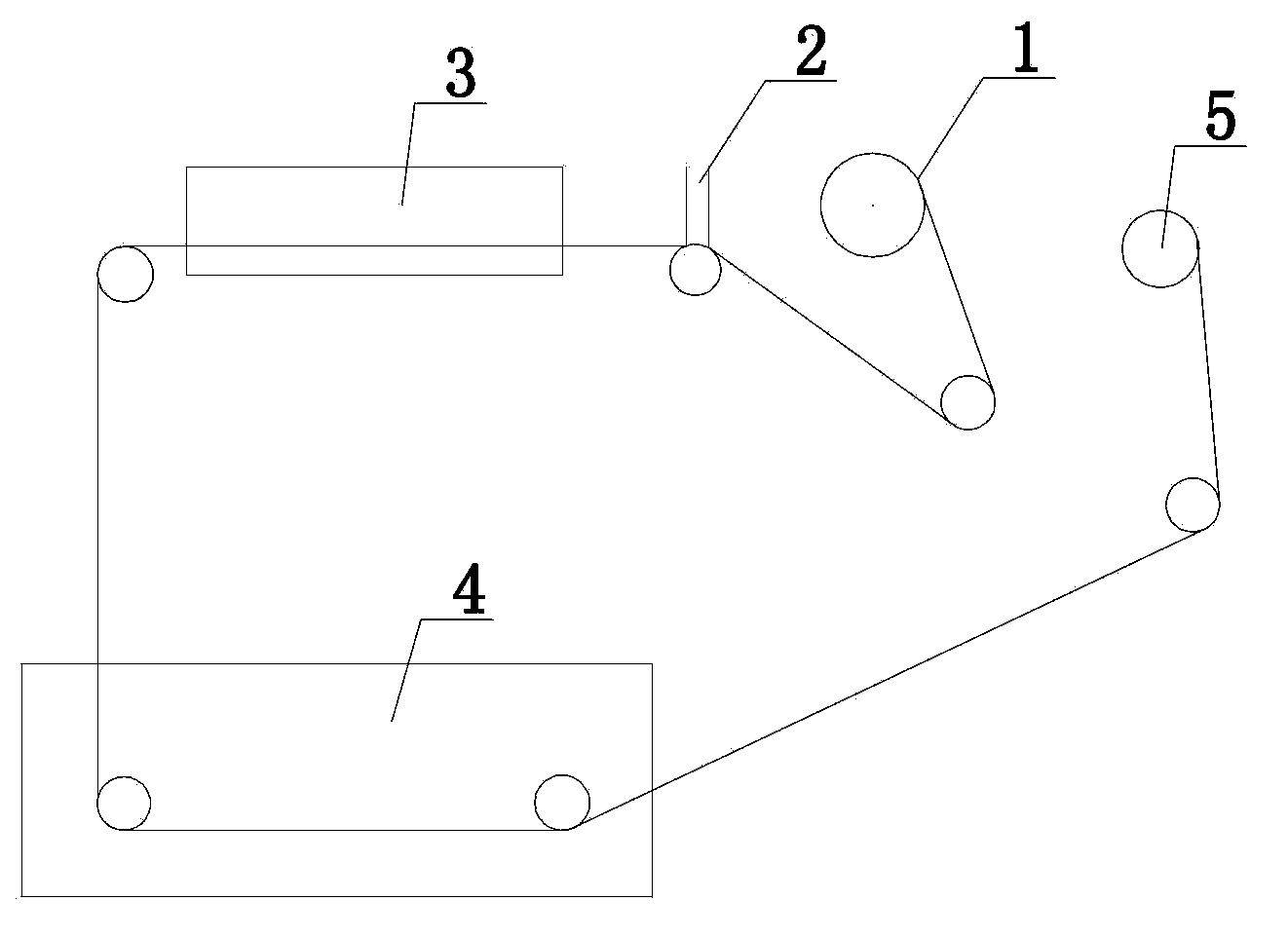

[0027] Dissolve 4 kg of lithium chloride and 4 kg of polyvinylpyrrolidone in 74 kg of N,N-dimethylacetamide, then add 18 kg of polyethersulfone, dissolve the mixture at 60°C at a constant temperature, and Degassing by heating at 50°C to obtain a casting solution. A certain amount of the prepared film casting solution was put into the trough 2, and the polyester non-woven fabric 1 was used as the support layer, and the thickness of the film was controlled to 0.25 mm by a feeler gauge. The non-woven fabric 1 passes through the trough 2 at a speed of 3 m / min driven by the motor 5, and the 0.25 mm thick casting liquid is scraped onto the non-woven fabric 1 by controlling the scraper in the trough 2. The relative humidity of the film-making room At 45%-50%, the temperature is 25°C-30°C; after coating the casting solution on the non-woven fabric 1, stay in the oven 3 at 90°C for 0.4 min, evaporate a part of the solvent, and then enter the gel tank 4 to solidify film forming. The p...

Embodiment 2

[0029] Dissolve 4 kg of lithium chloride and 4 kg of polyvinylpyrrolidone in 74 kg of N,N-dimethylacetamide, then add 18 kg of polyethersulfone, dissolve the mixture at a constant temperature of 60°C, and ℃ heating defoaming. A certain amount of casting solution was put into the trough 2, and the polyester non-woven fabric 1 was used as the support layer, and the thickness of the film was controlled to 0.25 mm by a feeler gauge. The non-woven fabric 1 passes through the trough 2 at a speed of 3 m / min driven by the motor 5, and the 0.25 mm thick casting liquid is scraped onto the non-woven fabric 1 by controlling the scraper in the trough 2. The relative humidity of the film-making room At 45%-50%, the temperature is 25°C-30°C; after coating the casting solution on the non-woven fabric 1, stay in the oven 3 at 90°C for 0.5 min, evaporate a part of the solvent, and then enter the gel tank 4 to solidify film forming. The prepared membrane was placed in tap water for more than 2...

Embodiment 3

[0031]Dissolve 6 kg of lithium chloride and 2 kg of polyvinylpyrrolidone in 74 kg of N,N-dimethylacetamide, then add 18 kg of polyethersulfone, dissolve the mixture at a constant temperature of 60°C, and ℃ heating defoaming. A certain amount of casting solution was put into the trough 2, and the polyester non-woven fabric 1 was used as the support layer, and the thickness of the film was controlled to 0.25 mm by a feeler gauge. The non-woven fabric 1 passes through the trough 2 at a speed of 3 m / min driven by the motor 5, and the 0.25 mm thick casting liquid is scraped onto the non-woven fabric 1 by controlling the scraper in the trough 2. The relative humidity of the film-making room At 45%-50%, the temperature is 25°C-30°C; after coating the casting solution on the non-woven fabric 1, stay in the oven 3 at 90°C for 0.4 min, evaporate a part of the solvent, and then enter the gel tank 4 to solidify film forming. The prepared membrane was placed in pure water for more than 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com