Pressure-sharing structure of double-tower-type gas separation equipment

A technology of gas separation and pressure equalization structure, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of not achieving the pressure equalization effect, low product gas concentration, and low gas production volume, etc., and achieve pressure equalization Good effect, reasonable trachea arrangement, and the effect of increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings.

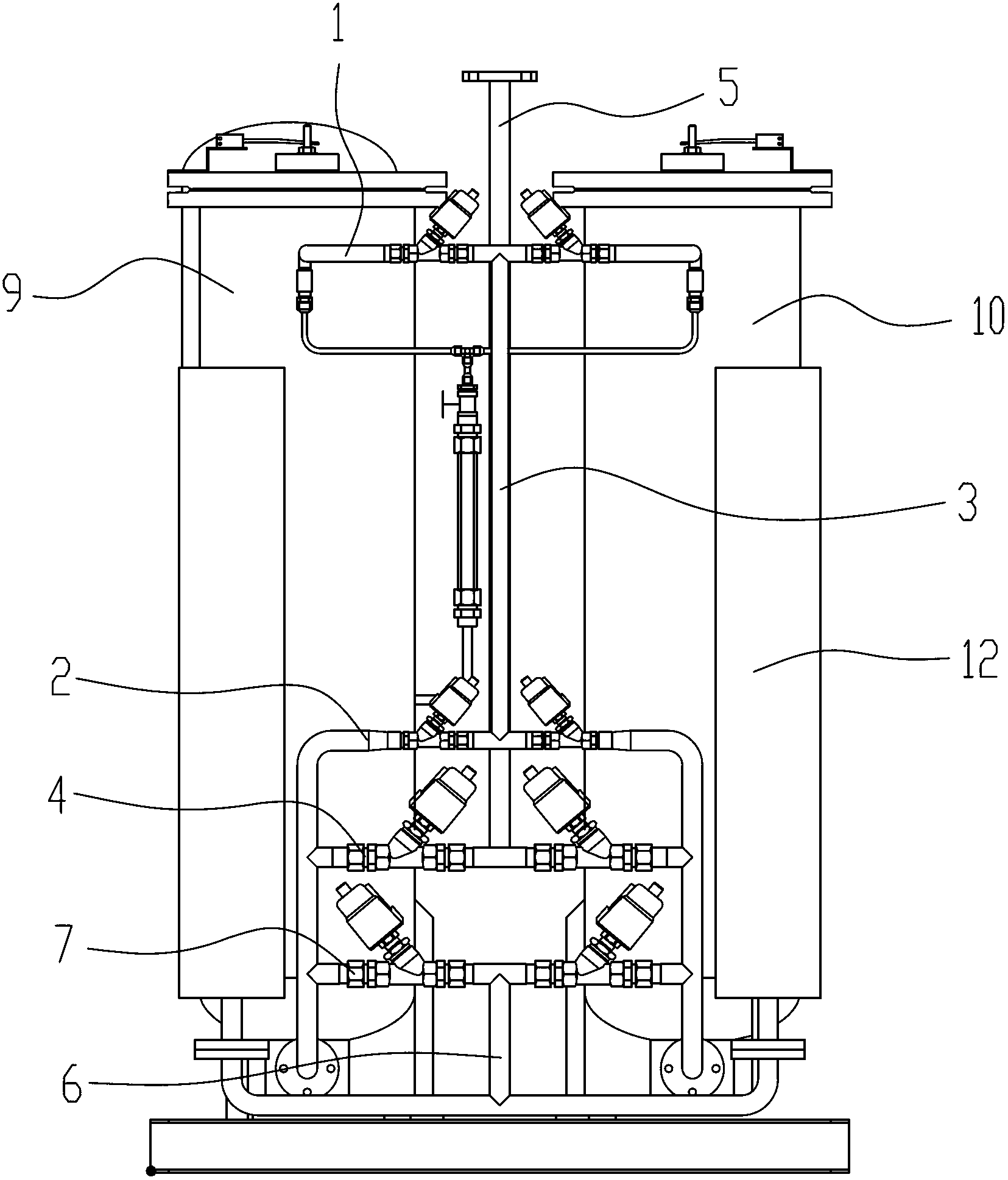

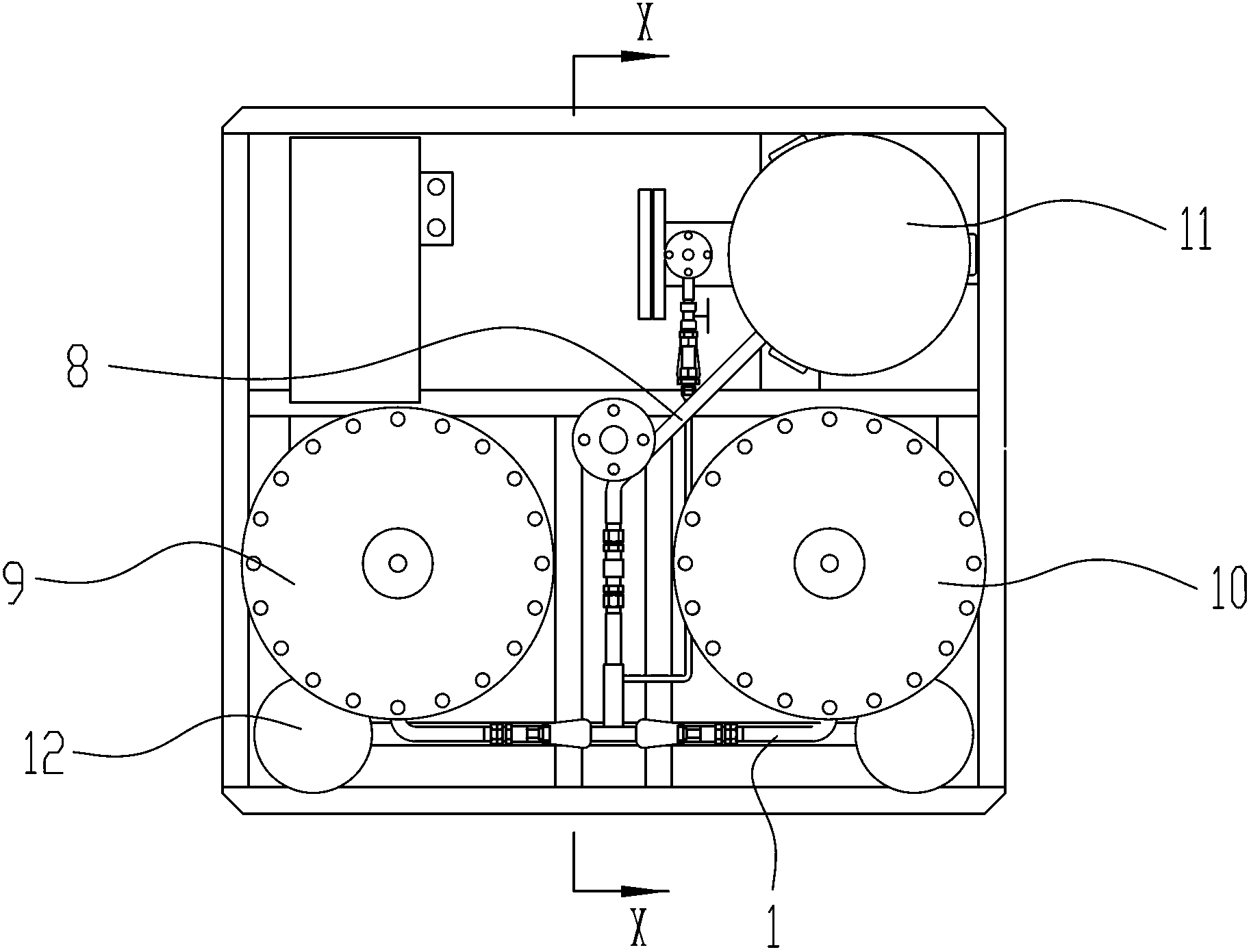

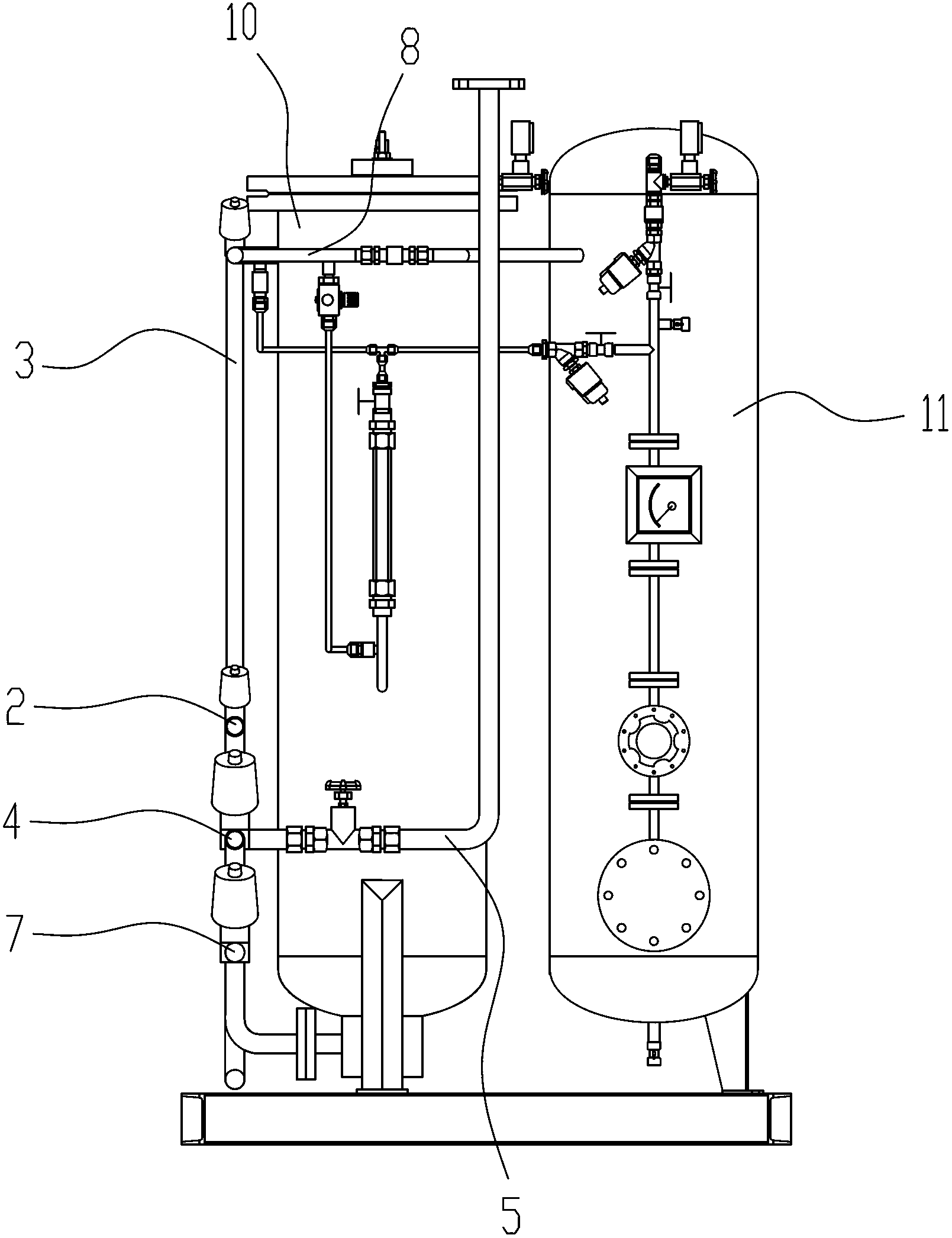

[0021] Such as Figure 1-Figure 4 As shown, the pressure equalization structure of a double-tower gas separation device described in this embodiment includes two adsorption towers, that is, tower A 9 and tower B 10 on the right side of tower A, and the upper ends of the tower body of the two adsorption towers are There is an airflow output port, and an airflow input port is opened at the lower end. The two adsorption towers form an airflow channel through a pressure equalization tube, and the output port of one tower is only connected with the input port of the other tower during pressure equalization.

[0022] The pressure equalizing pipe includes a first gas pipe 1 connected to the output ports of the two adsorption towers and a second gas pipe 2 connected to the input ports of the two adsorption towers. The first gas pipe 1 and the second gas pipe 2 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com